Difference between revisions of "Surface Analysis (KLA/Tencor Surfscan)"

Jump to navigation

Jump to search

| (30 intermediate revisions by 2 users not shown) | |||

| Line 12: | Line 12: | ||

}} |

}} |

||

==About== |

==About== |

||

| − | This system uses a laser-based scattering method to count size and distribution of particles (or other scattering defects) on a flat wafer surface. |

+ | This system uses a laser-based scattering method to count size and distribution of particles (or other scattering defects) on a flat wafer surface. |

| + | |||

| + | It can scan wafers in size from 4 to 8 inches. Piece-parts are more difficult but can be scanned with a custom recipe. |

||

| + | |||

| + | 4-inch wafers are the most standard size to measure. |

||

| + | |||

| + | For measuring very low particle counts accurately, purchase "low particle count" (LPC) wafers from a Silicon wafer vendor, and keep the wafers in the case and clean at all times until use. |

||

==Documentation== |

==Documentation== |

||

| + | ===Operating Procedures=== |

||

| − | *[[KLA-Tencor Surfscan - Standard Operating Procedure|Standard Operating Procedure]] |

||

| − | *[https://wiki.nanotech.ucsb.edu/w/images/9/96/Surfscan-Operation-Manual.pdf Operations Manual] |

||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| − | *[[Errors]] |

||

| − | ==Standard Recipes== |

||

| + | *[https://wiki.nanofab.ucsb.edu/w/images/a/a2/SURFSCAN_6200_122123_for_8inch_wafers.pdf Surfscan 6200 8inch wafers] * |

||

| − | *[https://drive.google.com/drive/u/0/folders/135jBoHKLJ0uoLyD6NlHt_pgco8NJjdCs Standard Recipes] |

||

| + | *[https://wiki.nanofab.ucsb.edu/w/images/1/1a/SURFSCAN_6200_122023_for_6inch_wafers.pdf Surfscan 6200 6inch wafers] * |

||

| + | *[https://wiki.nanofab.ucsb.edu/w/images/9/9f/SURFSCAN_6200_122123_for_4inch_wafers.pdf Surfscan 6200 4inch wafers] * |

||

| + | *[https://wiki.nanofab.ucsb.edu/w/images/a/a7/SURFSCAN_6200_122123_small_substrates.pdf Surfscan 6200 [Small samples, and 2inch and 3inch wafers]] * |

||

| + | |||

| + | **''You must water-mount your small sample or wafer(2inch or 3 inch) to a 4-inch wafer.'' |

||

| ⚫ | |||

| + | |||

| + | *[https://wiki.nanofab.ucsb.edu/w/images/2/29/Wafer_Particle_Count-Process_Traveler.pdf Wafer Scanning Instructions] |

||

| + | **''This is the procedure Staff uses to calibrate particle counts on our deposition tools.'' |

||

| + | |||

| + | ===Other Documentation=== |

||

| + | |||

*[https://wiki.nanotech.ucsb.edu/w/images/9/96/Surfscan-Operation-Manual.pdf Operations Manual] |

*[https://wiki.nanotech.ucsb.edu/w/images/9/96/Surfscan-Operation-Manual.pdf Operations Manual] |

||

| ⚫ | |||

| + | |||

| ⚫ | |||

| + | *[[Surfscan Errors and Workarounds|Common Errors & Workarounds]] |

||

==Examples== |

==Examples== |

||

| − | <br /> |

||

{| class="wikitable" |

{| class="wikitable" |

||

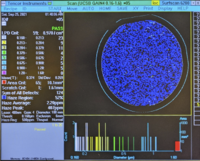

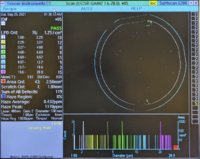

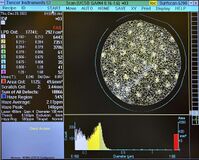

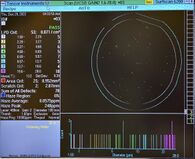

|+A low-particle 4-inch wafer example: |

|+A low-particle 4-inch wafer example: |

||

Latest revision as of 18:02, 2 February 2024

| ||||||||||||||||||||||||||

About

This system uses a laser-based scattering method to count size and distribution of particles (or other scattering defects) on a flat wafer surface.

It can scan wafers in size from 4 to 8 inches. Piece-parts are more difficult but can be scanned with a custom recipe.

4-inch wafers are the most standard size to measure.

For measuring very low particle counts accurately, purchase "low particle count" (LPC) wafers from a Silicon wafer vendor, and keep the wafers in the case and clean at all times until use.

Documentation

Operating Procedures

- Surfscan 6200 8inch wafers *

- Surfscan 6200 6inch wafers *

- Surfscan 6200 4inch wafers *

- Surfscan 6200 [Small samples, and 2inch and 3inch wafers] *

- You must water-mount your small sample or wafer(2inch or 3 inch) to a 4-inch wafer.

- Wafer Particle Count - Process Traveler

- Wafer Scanning Instructions

- This is the procedure Staff uses to calibrate particle counts on our deposition tools.

Other Documentation

- Operations Manual

- For detailed measurement info, it is highly recommended that you read the manual.

Examples

| Gain 4: Small Particles

(0.160µm – 1.60µm) |

Gain 2: Large Particles

(1.60µm – 28.0µm) |

|---|---|

|

|

| Gain 4: Small Particles

(0.160µm – 1.60µm) |

Gain 2: Large Particles

(1.60µm – 28.0µm) |

|---|---|

|

|