Difference between revisions of "PECVD Recipes"

| (438 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

{{recipes|Vacuum Deposition}} |

{{recipes|Vacuum Deposition}} |

||

| + | |||

=[[PECVD 1 (PlasmaTherm 790)]]= |

=[[PECVD 1 (PlasmaTherm 790)]]= |

||

| − | *[https://docs.google.com/spreadsheets/d/1a0XrY6HuJ6L9niThZYI-u4XH69Hnbe3jkm1qKmrR8Rg/edit#gid=sharing Particulates in PECVD#1 2015] |

||

| − | *[https://docs.google.com/spreadsheets/d/1YNiof68Veeh08s_NtG5aCWUXW7GWDDU00HAimV_l8_g/edit#gid=sharing Particulates in PECVD#1 2017] |

||

| − | == SiN deposition (PECVD #1) == |

||

| − | *[[media:New PECVD1-SiO2-standard recipe 2014 SiO2 standard recipe.pdf|SiN Standard Recipe]] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dEN6LV93LXlnbUhIWU1adVZWMWlXYnc&usp=drive_web#gid=sharing SiN Data 2014] |

||

| − | *[https://docs.google.com/spreadsheets/d/1phx1WficlUEg0xSahaAq4zrRk6m9Eb0ausO8wcAmXqs/edit#gid=sharing SiN Data 2015] |

||

| − | *[https://docs.google.com/spreadsheets/d/1VNSNTqnbE4SFk0HyhBAy3GJzi0jRQEs8cgk1v2_Uam8/edit#gid=sharing SiN Data 2016] |

||

| − | *[https://docs.google.com/spreadsheets/d/1TG1X2wpl2fWaHEtAHtpZFBVSCk1BQeGJQ8LA2M2qBJ0/edit#gid=sharing SiN Data 2017] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dElmTXZyOEZsOFdrMVhNLWpKXzVmNWc&usp=sharing SiN 1000A Thickness uniformity 2014] |

||

| − | *[https://docs.google.com/spreadsheets/d/1-pET1Eojooso5UHk90W-5uYByDDdrCyRnggqewxTmVg/edit#gid=sharing SiN 1000A Thickness uniformity 2015] |

||

| − | *[https://docs.google.com/spreadsheets/d/1V_-KzsdR-2tSnJGtUdQWokmnNIY949t0vdQOp7RfCgc/edit#gid=sharing SiN 1000A Thickness uniformity 2016] |

||

| − | *[https://docs.google.com/spreadsheets/d/1tM-a4VBEqpxr2G8PGGLTbsR6BQBmvqXNRBw0mikAUS0/edit#gid=sharing SiN 1000A Thickness uniformity 2017] |

||

| + | ===[https://docs.google.com/spreadsheets/d/1fTDNXxpf4tgNYLIEs_jvehG1KvtXqqTRDBI7sHNAVvo/edit#gid=1270764394 PECVD 1 Process Control Plots] - Plots of all process control data=== |

||

| − | == SiO<sub>2</sub> deposition (PECVD #1) == |

||

| − | *[[media:New PECVD1-SiN-standard recipe 2014 SiN standard recipe.pdf|SiO<sub>2</sub> Standard Recipe]] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dEw0bjFEdTF2SUhRa25Ca0d0SzBha3c&usp=drive_web#gid=sharing SiO<sub>2</sub> Data 2014] |

||

| − | *[https://docs.google.com/spreadsheets/d/1JWNUcH8l90xif-0BhYKJee9nXxE4hnvvp6N2NtZLYXY/edit#gid=sharing SiO<sub>2</sub> Data 2015] |

||

| − | *[https://docs.google.com/spreadsheets/d/1F2pfsVnbUgaE9tsm8HZMlY6cyt-nhui0IpvGc6udhDU/edit#gid=sharing SiO<sub>2</sub> Data 2016] |

||

| − | *[https://docs.google.com/spreadsheets/d/1MblK5Zr5Skfw0s9Hdhqr_cCwN-nCgM-ofZnsAyvVRq8/edit#gid=sharing SiO<sub>2</sub> Data 2017] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dDQ3VEtZQVRpdVdlbGtIZHpTNmFzNmc&usp=drive_web#gid=sharing SiO<sub>2</sub> 1000A Thickness uniformity 2014] |

||

| − | *[https://docs.google.com/spreadsheets/d/1NQy-ADou6f2NBU-9jZG8KME1lOz0X5mh6HZV9_jPGes/edit#gid=sharing SiO<sub>2</sub> 1000A Thickness uniformity 2015] |

||

| − | *[https://docs.google.com/spreadsheets/d/1WUCm_dWpxKTjfFf1rNfLuxvwMxsyCYON_OZ3gb50L_s/edit#gid=sharing SiO<sub>2</sub> 1000A Thickness uniformity 2016] |

||

| − | *[https://docs.google.com/spreadsheets/d/1dpC_AkPD-etIH6fVuQqLfd4UMNQCEtcqhvmBpwbEncE/edit#gid=sharing SiO<sub>2</sub> 1000A Thickness uniformity 2017] |

||

| + | ==SiO<sub>2</sub> deposition (PECVD #1)== |

||

| + | *[https://docs.google.com/spreadsheets/d/1wloq6HJw5RQIvmeKcBn3xvE_917R6jF_K-btCHjsiIM/edit#gid= SiO<sub>2</sub><nowiki> [PECVD 1] Standard Recipe</nowiki>] |

||

| − | == OTHER recipes: LS SiN and SiO<sub>x</sub>N<sub>y</sub> deposition (PECVD #1) == |

||

| − | <!-- Placeholders - Not uploaded yet--> |

||

| − | *[[media:New PECVD1-LS SIN-Turner05recipe 2014 LS SIN recipe.pdf|LS SiN Standard Recipe]] |

||

| − | *[https://docs.google.com/spreadsheets/d/1Joz0az9TGZWQc4CiMQJZzLBbNFbx_hH2Oc0B4NNJmYk/edit#gid=sharing LS SiN Data 2014] |

||

| − | *[https://docs.google.com/spreadsheets/d/1xIzc2CufRYNSfAtsOXpw3IzHreeu42BWrLBV0kzP6kA/edit#gid=sharing LS SiN 1000A Thickness uniformity 2014] |

||

| − | *[[media:New PECVD1-LS SION-recipe 2014 LS SION recipe.pdf|SiO<sub>x</sub>N<sub>y</sub> Standard Recipe]] |

||

| − | *[https://docs.google.com/spreadsheets/d/1rixyzAAq6q08M5OwvZiDVoh3K8B566XKM-UZAQIAnsg/edit#gid=sharing SiO<sub>x</sub>N<sub>y</sub> Data 2014] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dEttR2JSTkRoamR0SUZ4bE5QUW9uS2c&usp=sharing SiO<sub>x</sub>N<sub>y</sub>1000A Thickness uniformity 2014] |

||

| + | *[https://docs.google.com/spreadsheets/d/1fTDNXxpf4tgNYLIEs_jvehG1KvtXqqTRDBI7sHNAVvo/edit#gid=0 SiO<sub>2</sub><nowiki> [PECVD 1] Current Process Control Data</nowiki>] |

||

| − | =[[PECVD 2 (Advanced Vacuum)]]= |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/Old_Deposition_Data_-_2021-12-15#SiO2_deposition_.28PECVD_.231.29 SiO<sub>2</sub><nowiki> [PECVD 1] Historical Data</nowiki>] - Oct. 2021 and earlier |

||

| − | *[https://docs.google.com/spreadsheets/d/1kj0SWxRpnPRoGld8k3sW-3yK1iPm3buTkvlJSN5YPV4/edit#gid=sharing Particulates in Advanced PECVD#2 2015 ] |

||

| − | *[https://docs.google.com/spreadsheets/d/1ICgt-fgTvNPbE_65x5jUsqy8JjHVv5WUvmE7g7VUbsI/edit#gid=sharing Particulates in Advanced PECVD#2 2017 ] |

||

| − | == SiO<sub>2</sub> deposition (PECVD #2) == |

||

| − | *[[media:New Adv PECVD OXIDE 300C standard recipe OXIDE Standard Recipe.pdf|Oxide Standard Recipe]] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dGJZaGtDTVRqa1BRdW5iU1N1Y01jd0E&usp=drive_web#gid=sharing Oxide Data 2014] |

||

| − | *[https://docs.google.com/spreadsheets/d/1d5boeJRWWgMqvQe6nVM7m8s3KAcS4Yp2L5CEU9svkX4/edit#gid=sharing Oxide Data 2015] |

||

| − | *[https://docs.google.com/spreadsheets/d/1XQRcTJdw9AIMPAUsH0n9Ic9Fe1_xGDSvAxD4gVc9FBw/edit#gid=sharing Oxide data 2016] |

||

| − | *[https://docs.google.com/spreadsheets/d/1vcaHwraMGNHuRxgWwGp78EJf4T3Jk182wxoCz_neuck/edit#gid=sharing Oxide Data 2017] |

||

| − | *[https://docs.google.com/spreadsheets/d/15SocIqWQvBKSvT5oCWoZAURLaaqb9KosxCN2rueZQN8/edit#gid=sharing New Data-300nm SiO<sub>2</sub> 2017] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dDRjSHEtYUZRUTg4azE2U0JGUTg2M1E#gid=sharing Oxide Thickness Uniformity 2014] |

||

| − | *[https://docs.google.com/spreadsheets/d/16pZHcGwesXB1mMPwntOudBIlPvRh6A6DI37DEwyYfPw/edit#gid=sharing Oxide Thickness Uniformity 2015] |

||

| − | *[https://docs.google.com/spreadsheets/d/10OEuANVNmHqWvx-92zibechIrHK5kgqSK4B_O_O3-YI/edit#gid=sharing Oxide Thickness Uniformity 2016] |

||

| − | *[https://docs.google.com/spreadsheets/d/19JjJYdFNFzO685Hp9hODVRFAYF5bP3IEYGTRGQjqLN4/edit#gid=sharing Oxide Thickness Uniformity 2017] |

||

| − | == |

+ | ==SiN deposition (PECVD #1)== |

| − | *[[media:New Adv PECVD-Nitride2 300C standard recipe Nitride2 Standard Recipe.pdf|Nitride2 Standard Recipe]] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dDE0R3FlenNPa2txNmRldTczMXZNNnc#gid=sharing Nitride2 Data 2014] |

||

| − | *[https://docs.google.com/spreadsheets/d/1SkYqOwgjUyMaFBPhuTjMvBTXu0KdQFNmITryF_OVi8o/edit#gid=sharing Nitride2 Data 2015] |

||

| − | *[https://docs.google.com/spreadsheets/d/1HJszgZyEZR9ZsiJpQM6pdsoQ6pWwI6brXasdmfDRoBQ/edit#gid=sharing Nitride2 Data 2016] |

||

| − | *[https://docs.google.com/spreadsheets/d/1f3JBEnr7lf0yIMlzlOYKv_bXlIDyXt8vec_rSVJIoOk/edit#gid=sharing Nitride2 Data 2017] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dERkYm85bGtYQVpjVk5GTGJuMkg2anc&usp=drive_web#gid=sharing Nitride2 Thickness Uniformity 2014] |

||

| − | *[https://docs.google.com/spreadsheets/d/14_dYQu3z31fF_oxsUUX8BmDucgv6B07xB3_zqP0HmvM/edit#gid=sharing Nitride2 Thickness Uniformity 2015] |

||

| − | *[https://docs.google.com/spreadsheets/d/1qBHs7uALM2OdE-yXOq4uZk6aUQEjZRjG1C6RcMEf0sk/edit#gid=sharing Nitride2 Thickness Uniformity 2016] |

||

| − | *[https://docs.google.com/spreadsheets/d/1WJcYzHUjLrWpys_i-Q96FN_lBDBufpXZKZVEX_gri_Q/edit#gid=sharing Nitride2 Thickness Uniformity 2017] |

||

| − | *[[media:SiNx_Films_by_PECVD2.pdf|SiNx Film Stress vs LF and HF Duration Time, and Gas Flowing-rate]] |

||

| + | *[https://docs.google.com/spreadsheets/d/1DGU745SeunYz4sLs1LpGKbtOYX-tQyBHEvVYcMxHRKE/edit#gid= Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 1] Standard Recipe</nowiki>] |

||

| − | ==LS SiN deposition (PECVD #2) == |

||

| + | *[https://docs.google.com/spreadsheets/d/1fTDNXxpf4tgNYLIEs_jvehG1KvtXqqTRDBI7sHNAVvo/edit#gid=98787450 Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 1] Current Process Control Data</nowiki>] |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/Old_Deposition_Data_-_2021-12-15#SiN_deposition_.28PECVD_.231.29 Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 1] Historical Data</nowiki>] - Oct. 2021 and earlier |

||

| + | ==Low Stress Si<sub>3</sub>N<sub>4</sub> (PECVD#1)== |

||

| − | *[[media:Adv PECVD-LS Nitride2 300C standard recipe .pdf|LS Nitride2 Standard Recipe]] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dEZvWVhzS1pHUXZkOGcyQWZ4LTNBWGc&usp=drive_web#gid=sharing LS Nitride2 Data 2014] |

||

| − | *[https://docs.google.com/spreadsheets/d/16Q6BrPoNiFP0elVoSGwXRfQdHXzAXOgiyqKmEw-4kII/edit#gid=sharing LS Nitride2 Data 2015] |

||

| − | *[https://docs.google.com/spreadsheets/d/1GZ58eFzD-T8DJ2Nsaj74u6cvawzsOI2DmMit6Z7vqys/edit#gid=sharing LS Nitride2 Data 2016] |

||

| − | *[https://docs.google.com/spreadsheets/d/1gGIWqkCnykPgBc3prhXExT7QcNjWm2HdbTtwugNqm18/edit#gid=sharing LS Nitride2 Data 2017] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dENSak1ZNnVaVTFEQTBzdDJMSDlDTFE&usp=drive_web#gid=1=sharing LS Nitride2 Thickness Uniformity 2014] |

||

| − | *[https://docs.google.com/spreadsheets/d/1LpkaOpr7oNoyvxFkineD7i9FspO6LweJMulvZHJM5Zc/edit#gid=sharing LS Nitride2 Thickness Uniformity 2015] |

||

| − | *[https://docs.google.com/spreadsheets/d/1FRzW9BaIPF2D3cxPgjLq8hbvrBHXDNkiW6DiPVKQBRM/edit#gid=sharing LS Nitride2 Thickness Uniformity 2016] |

||

| − | *[https://docs.google.com/spreadsheets/d/1vyrgvdEZFgnQUilpa5Ka2nOfowY8zlmJfbQ77EamNBg/edit#gid=sharing LS Nitride2 Thickness Uniformity 2017] |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/images/4/4a/New_PECVD1-LS_SIN-Turner05recipe_2014_LS_SIN_recipe.pdf Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 1] Standard Recipe</nowiki>] |

||

| − | == Amorphous-Si deposition (PECVD #2) == |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/Old_Deposition_Data_-_2021-12-15#Low-Stress_SiN_-_LS-SiN_.28PECVD.231.29 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 1] Historical Data</nowiki>] - 2021-10 and earlier |

||

| − | *[[media:03-Amorphous-Si-PECVD-2.pdf|Amorphous Si Deposition Recipe]] |

||

| − | *[[media:ASi_deposition_and_film_stress_using_AV_dep_tool.pdf|Amorphous Si Films and Their Stress]] |

||

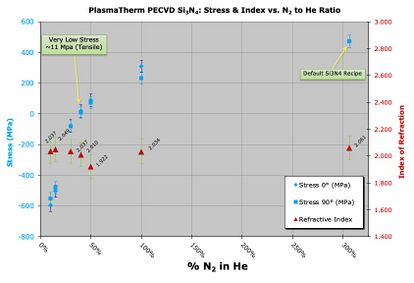

| + | :[[File:PECVD1 SiN Stress vs. N2 plot.jpg|alt=plot of SiN stress and Refractive Index vs. N2 flow. |none|thumb|414x414px|Example of Si<sub>3</sub>N<sub>4</sub> modified stress via. varying N<sub>2</sub> flow. Refractive index is relatively constant (one outlier), and stress varies continuously from tensile to compressive. ([[Demis D. John]] 2011, [https://engineering.ucsb.edu/people/daniel-blumenthal Blumenthal Group])]] |

||

| − | = [[ICP-PECVD (Unaxis VLR)]] = |

||

| − | ==SiN deposition (Unaxis VLR) == |

||

| − | === SiN (2% SiH<sub>4</sub>) === |

||

| − | {| border="1" class="wikitable" style="border: 1px solid #D0E7FF; background-color:#ffffff; text-align:center;" |

||

| − | |- bgcolor="#D0E7FF" |

||

| − | !width=350 align=center|50° (pinholes) |

||

| − | !width=350 align=center|100° (pinholes) |

||

| − | !width=350 align=center|250° |

||

| − | |-align=left |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-5W-50C-High-Stress.pdf|SiN Deposition Recipe (5W 50° High Stress)]] |

||

| − | *[[Media:PECVD2-SiN-Recipe-50W-50C-Medium-Stress.pdf|SiN Deposition Recipe (50W 50° Medium Stress)]] |

||

| − | *[[Media:PECVD2-SiN-Recipe-120W-50C-Low-Stress.pdf|SiN Deposition Recipe (120W 50° Low Stress)]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-5W-100C-High-Stress.pdf|SiN Deposition Recipe (5W 100° High Stress)]] |

||

| − | *[[Media:PECVD2-SiN-Recipe-50W-100C-Medium-Stress.pdf|SiN Deposition Recipe (50W 100° Medium Stress)]] |

||

| − | *[[Media:PECVD2-SiN-Recipe-120W-100C-Low-Stress.pdf|SiN Deposition Recipe (120W 100° Low Stress)]] |

||

| − | *[[Media:PECVD2-SiNx-l.s.-Comparison table-2% SiH4-100C-120W.pdf|Comparison Table SiNx (120W 100° Low Stress)]] |

||

| − | *[[Media:PECVD2-SiNx-medium-Comparison table-2% SiH4-100C-120W.pdf|Comparison Table SiNx (50W 100° Medium Stress)]] |

||

| − | *[[Media:PECVD2-SiNx -h.s.-Comparison table-2% SiH4-100C-120W.pdf|Comparison Table SiNx (5W 100° High Stress)]] |

||

| − | *[[Media:PECVD2-SiNx-medium stress-SEM-2% SiH4-100C-50W.pdf|SiNx SEM images (50W 100° Medium Stress)]] |

||

| − | *[[Media:PECVD2-SiNx-high stress-SEM-2% SiH4-100C-5W.pdf|SiNx SEM images (5W 100° High Stress)]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-5W-250C-High-Stress.pdf|SiN Deposition Recipe (5W 250° High Stress)]] |

||

| − | *[[Media:PECVD2-SiN-Recipe-50W-250C-Medium-Stress.pdf|SiN Deposition Recipe (50W 250° Medium Stress)]] |

||

| − | *[[Media:PECVD2-SiN-Recipe-120W-250C-Low-Stress.pdf|SiN Deposition Recipe (120W 250° Low Stress)]] |

||

| − | *[[Media:PECVD2-SiNx-l.s.-Comparison table-2% SiH4-100C-120W.pdf|Comparison Table SiNx (120W 250° Low Stress)]] |

||

| − | *[[Media:PECVD2-SiNx-medium-Comparison table-2% SiH4-100C-120W.pdf|Comparison Table SiNx (50W 250° Medium Stress)]] |

||

| − | *[[Media:PECVD2-SiNx -h.s.-Comparison table-2% SiH4-100C-120W.pdf|Comparison Table SiNx (5W 250° High Stress)]] |

||

| − | *[[Media:28-Very-low-pin-hole-density_SiNx_film_at_300_C.pdf|Very-Low-Pin-Hole-Density SiNx Recipe(25W 300°)]] |

||

| − | |- |

||

| − | |} |

||

| − | == |

+ | ==SiO<sub>x</sub>N<sub>y</sub> deposition (PECVD #1)== |

| − | {| border="1" class="wikitable" style="border: 1px solid #D0E7FF; background-color:#ffffff; text-align:center;" |

||

| − | |- bgcolor="#D0E7FF" |

||

| − | !width=350 align=center|50° (pinholes) |

||

| − | !width=350 align=center|100° (pinholes) |

||

| − | !width=350 align=center|250° |

||

| − | |-align=left |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-NoAr-5W-50C-High-Stress.pdf|SiN Deposition Recipe - No Ar (5W 50° High Stress)]] |

||

| − | *[[Media:41-High-stress_SiNx_at_50_C_using_Unaxis_ICP_deposition_tool.pdf|Film Properties of High-stress SiN<sub>x</sub> (No Ar, 5W, 50°)]] |

||

| − | *[[Media:PECVD2-SiN-Recipe-NoAr-50W-50C-Medium-Stress.pdf|SiN Deposition Recipe - No Ar (50W 50° Medium Stress)]] |

||

| − | *[[Media:36-Medium-stress_SiNx_using_Unaxis_ICP_deposition_tool-a.pdf|Film Properties of Medium-stress SiN<sub>x</sub> (No Ar, 50W, 50°)]] |

||

| − | *[[Media:PECVD2-SiN-Recipe-NoAr-120W-50C-Low-Stress.pdf|SiN Deposition Recipe - No Ar (120W 50° Low Stress)]] |

||

| − | *[[Media:40-Low-stress_SiNx_at_50_C_using_Unaxis_ICP_deposition_tool.pdf|Film Properties of Low-stress SiN<sub>x</sub> (No Ar, 120W, 50°)]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-NoAr-5W-100C-High-Stress.pdf|SiN Deposition Recipe - No Ar (5W 100° High Stress)]] |

||

| − | *[[Media:38-High-stress_SiNx_at_100_C_using_Unaxis_ICP_deposition_tool.pdf|Film Properties of high-stress SiN<sub>x</sub> (No Ar, 5W, 100°)]] |

||

| − | *[[Media:PECVD2-SiN-Recipe-NoAr-50W-100C-Medium-Stress.pdf|SiN Deposition Recipe - No Ar (50W 100° Medium Stress)]] |

||

| − | *[[Media:39-Medium-stress_SiNx_at_100C_using_Unaxis_ICP_deposition_tool.pdf|Film Properties of Medium-stress SiN<sub>x</sub> (No Ar, 50W, 100°)]] |

||

| − | *[[Media:PECVD2-SiN-Recipe-NoAr-120W-100C-Low-Stress.pdf|SiN Deposition Recipe - No Ar (120W 100° Low Stress)]] |

||

| − | *[[Media:37-Low-stress_SiNx_at_100_C_using_Unaxis_ICP_deposition_tool.pdf|Film Properties of Low-stress SiN<sub>x</sub> (No Ar, 120W, 100°)]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-NoAr-5W-250C-High-Stress.pdf|SiN Deposition Recipe - No Ar (5W 250° High Stress)]] |

||

| − | *[[Media:34-High-stress_SiNx_at_250_C_using_Unaxis_ICP_deposition_tool.pdf|Film Properties of High-stress SiN<sub>x</sub> (No Ar, 5W, 250°)]] |

||

| − | *[[Media:PECVD2-SiN-Recipe-NoAr-50W-250C-Medium-Stress.pdf|SiN Deposition Recipe - No Ar (50W 250° Medium Stress)]] |

||

| − | *[[Media:36-Medium-stress_SiNx_using_Unaxis_ICP_deposition_tool-a.pdf|Film Properties of Medium-stress SiN<sub>x</sub> (No Ar, 50W, 250°)]] |

||

| − | *[[Media:PECVD2-SiN-Recipe-NoAr-120W-250C-Low-Stress.pdf|SiN Deposition Recipe - No Ar (120W 250° Low Stress)]] |

||

| − | *[[Media:35-Low-stress_SiNx_at_250_C_using_Unaxis_ICP_deposition_tool.pdf|Film Properties of Low-stress SiN<sub>x</sub> (No Ar, 120W, 250°)]] |

||

| − | |- |

||

| − | |} |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/images/2/24/New_PECVD1-LS_SION-recipe_2014_LS_SION_recipe.pdf SiO<sub>x</sub>N<sub>y</sub> Standard Recipe] |

||

| − | === SiN (2% SiH<sub>4</sub> - No-Ar - Extra N<sub>2</sub>) === |

||

| + | *[https://docs.google.com/spreadsheets/d/1rixyzAAq6q08M5OwvZiDVoh3K8B566XKM-UZAQIAnsg/edit#gid=sharing SiO<sub>x</sub>N<sub>y</sub> Data 2014] - ''Rate, Index etc.'' |

||

| − | {| border="1" class="wikitable" style="border: 1px solid #D0E7FF; background-color:#ffffff; text-align:center;" |

||

| + | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dEttR2JSTkRoamR0SUZ4bE5QUW9uS2c&usp=sharing SiO<sub>x</sub>N<sub>y</sub>1000A Thickness uniformity 2014] |

||

| − | |- bgcolor="#D0E7FF" |

||

| − | !width=350 align=center|50° (pinholes) |

||

| − | !width=350 align=center|100° (pinholes) |

||

| − | !width=350 align=center|250° |

||

| − | |-align=left |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-NoAr-ExtraN2-120W-50C-Low-Stress.pdf|SiN Deposition Recipe - No Ar Extra N<sub>2</sub> (120W 50° Low Stress)]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-NoAr-ExtraN2-120W-100C-Low-Stress.pdf|SiN Deposition Recipe - No Ar Extra N<sub>2</sub> (120W 100° Low Stress)]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-NoAr-ExtraN2-120W-250C-Low-Stress.pdf|SiN Deposition Recipe - No Ar Extra N<sub>2</sub> (120W 250° Low Stress)]] |

||

| − | |- |

||

| − | |} |

||

| + | ==Standard Cleaning Procedure (PECVD #1)== |

||

| − | === SiN (100% SiH<sub>4</sub> ) === |

||

| + | The cleaning procedure is very important in order to have consistent result on this tool and also to keep particulate count low. After each deposition you should clean the tool following instructions carefully. The clean is done in two steps: |

||

| − | {| border="1" class="wikitable" style="border: 1px solid #D0E7FF; background-color:#ffffff; text-align:center;" |

||

| − | |- bgcolor="#D0E7FF" |

||

| − | !width=350 align=center|50° (pinholes) |

||

| − | !width=350 align=center|100° (pinholes) |

||

| − | !width=350 align=center|250° |

||

| − | |-align=left |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-Low stress SiNx-100%SiH4-120W-50C.pdf|SiN Deposition Recipe (120W 50° Low Stress)]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-Low stres SiNx-100% SiH4-120W-100C.pdf|SiN Deposition Recipe (120W 100° Low Stress)]] |

||

| − | *[[Media:PECVD2-SiN-Table-Low stres SiNx-100% SiH4-120W-100C.pdf|SiN Comparison Table 120W-100(250)C]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-Low stress SiNx-100% SiH4-120W-250C.pdf|SiN Deposition Recipe (120W 250° Low Stress)]] |

||

| − | *[[Media:PECVD2-SiN-Table-Low stres SiNx-100% SiH4-120W-100C.pdf|SiN Comparison Table 120W, 100(250)C ]] |

||

| − | |- align=left |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-Medium stress SiNx-100%SiH4-120W-50C.pdf|SiN Deposition Recipe (50W 50° Medium Stress)]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-Medium stres SiNx-100% SiH4-120W-100C.pdf|SiN Deposition Recipe (50W 100° Medium Stress)]] |

||

| − | *[[Media:PECVD2-SiN-Table-Low stres SiNx-100% SiH4-120W-100C.pdf|SiN Comparison Table 50W, 100(250)C]] |

||

| − | *[[Media:27-SiNx_Film_(Bias%3D50W)_Sidewall_Coverage.pdf|SiN SEM sidewall coverage]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiN-Recipe-Medium stress SiNx-100% SiH4-120W-250C.pdf|SiN Deposition Recipe (50W 250° Medium Stress)]] |

||

| − | *[[Media:PECVD2-SiN-Table-Low stres SiNx-100% SiH4-120W-100C.pdf|SiN ComparisonTable 50W, 100(250)C]] |

||

| − | |- |

||

| − | |} |

||

| + | #Wet cleaning (start cleaning by using a cleanroom wipe sprayed with DI. Wipe chamber sidewalls with it. Finish cleaning by using the cleanroom wipe sprayed with IPA. ) |

||

| − | ==SiO<sub>2</sub> deposition (Unaxis VLR) == |

||

| + | #Load the recipe for cleaning "CF4/O2 Clean" (edit the recipe and change ONLY time of cleaning). Follow instructions regarding a required time for cleaning. |

||

| − | === SiO<sub>2</sub> (2% SiH<sub>4</sub>) === |

||

| + | # |

||

| − | {| border="1" class="wikitable" style="border: 1px solid #D0E7FF; background-color:#ffffff; text-align:center;" |

||

| − | |- bgcolor="#D0E7FF" |

||

| − | !width=350 align=center|50° |

||

| − | !width=350 align=center|100° |

||

| − | !width=350 align=center|250° |

||

| − | |-align=left |

||

| − | | |

||

| − | *[[Media:PECVD2-SiO2Recipe-5W-50C.pdf|SiO<sub>2</sub> Deposition Recipe (5W 50°)]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiO2Recipe-5W-100C.pdf|SiO<sub>2</sub> Deposition Recipe (5W 100°)]] |

||

| − | *[[Media:SiO2 film Unaxis ICP vs PECVD I.pdf|SiO<sub>2</sub> film Unaxis ICP vs PECVD I]] |

||

| − | *[[Media:SEM pictures SiO2 100C.pdf|SiO<sub>2</sub> SEM pictures 100C]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiO2Recipe-5W-250C.pdf|SiO<sub>2</sub> Deposition Recipe (5W 250°)]] |

||

| − | *[[Media:SiO2 film Unaxis ICP vs PECVD I.pdf|SiO<sub>2</sub> film Unaxis ICP vs PECVD I]] |

||

| − | |- |

||

| − | |} |

||

| + | {| class="wikitable" |

||

| − | === SiO<sub>2</sub> (2% SiH<sub>4</sub> - No Ar) === |

||

| + | |+Table of Cleaning Times |

||

| − | {| border="1" class="wikitable" style="border: 1px solid #D0E7FF; background-color:#ffffff; text-align:center;" |

||

| + | !Film Dep'd |

||

| − | |- bgcolor="#D0E7FF" |

||

| + | !Cleaning Time |

||

| − | !width=350 align=center|50° |

||

| − | !width=350 align=center|100° |

||

| − | !width=350 align=center|250° |

||

| − | |-align=left |

||

| − | | |

||

| − | *[[Media:PECVD2-SiO2-Recipe-NoAr-50C.pdf|SiO<sub>2</sub> Deposition Recipe - No Ar (50°)]] |

||

| − | *[[Media:29-UnaxisPM3-SiO2-SiH4-O2-He.pdf|SiO<sub>2</sub> Film Properties-No Ar]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiO2-Recipe-NoAr-100C.pdf|SiO<sub>2</sub> Deposition Recipe - No Ar (100°)]] |

||

| − | *[[Media:29-UnaxisPM3-SiO2-SiH4-O2-He.pdf|SiO<sub>2</sub> Film Properties-No Ar]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiO2-Recipe-NoAr-250C.pdf|SiO<sub>2</sub> Deposition Recipe - No Ar (250°)]] |

||

| − | *[[Media:29-UnaxisPM3-SiO2-SiH4-O2-He.pdf|SiO<sub>2</sub> Film Properties-No Ar]] |

||

|- |

|- |

||

| + | |SiO<sub>2</sub> |

||

| − | |} |

||

| + | |TBD |

||

| − | |||

| + | |- |

||

| − | === SiO<sub>2</sub> (100% SiH<sub>4</sub> HDR) === |

||

| + | |Si<sub>3</sub>N<sub>4</sub> |

||

| − | {| border="1" class="wikitable" style="border: 1px solid #D0E7FF; background-color:#ffffff; text-align:center;" |

||

| + | |TBD |

||

| − | |- bgcolor="#D0E7FF" |

||

| − | !width=350 align=center|50° |

||

| − | !width=350 align=center|100° |

||

| − | !width=350 align=center|250° |

||

| − | |-align=left |

||

| − | | |

||

| − | *[[Media:SiO2 100% SiH4 HDR 50C.pdf|SiO<sub>2</sub> Deposition Recipe - HDR (50°)]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiO2-Recipe-100%SiH4-HDR-100C.pdf|SiO<sub>2</sub> Deposition Recipe - HDR (100°)]] |

||

| − | *[[Media:PECVD2-SiO2-HDR-100% SiH4.pdf|SiO<sub>2</sub> Comparison Table - HDR (100°)]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiO2-Recipe-100%SiH4-HDR-250C.pdf|SiO<sub>2</sub> Deposition Recipe - HDR (250°)]] |

||

| − | *[[Media:PECVD2-SiO2-HDR-100% SiH4.pdf|SiO<sub>2</sub> Comparison Table - HDR (250°)]] |

||

|- |

|- |

||

| + | |SiOxNy |

||

| + | |Same as XYZ |

||

|} |

|} |

||

| + | # |

||

| − | === SiO<sub>2</sub> (100% SiH<sub>4</sub> LDR) === |

||

| − | {| border="1" class="wikitable" style="border: 1px solid #D0E7FF; background-color:#ffffff; text-align:center;" |

||

| − | |- bgcolor="#D0E7FF" |

||

| − | !width=350 align=center|50° |

||

| − | !width=350 align=center|100° |

||

| − | !width=350 align=center|250° |

||

| − | |-align=left |

||

| − | | |

||

| − | *[[Media:PECVD2-SiO2-Recipe-100%SiH4-LDR-50C.pdf|SiO<sub>2</sub> Deposition Recipe - LDR (50°)]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiO2-Recipe-100%SiH4-LDR-100C.pdf|SiO<sub>2</sub> Deposition Recipe - LDR (100°)]] |

||

| − | *[[Media:PECVD2-SiO2-LDR-100% SiH4.pdf|SiO<sub>2</sub> Comparison Table - LDR (100°)]] |

||

| − | *[[Media:PECVD2-SiO2-SEM-LDR SiO2-100% SiH4-100C-15W.pdf|SiO<sub>2</sub> SEM sidewall coverage]] |

||

| − | | |

||

| − | *[[Media:PECVD2-SiO2-Recipe-100%SiH4-LDR-250C.pdf|SiO<sub>2</sub> Deposition Recipe - LDR (250°)]] |

||

| − | *[[Media:PECVD2-SiO2-LDR-100% SiH4.pdf|SiO<sub>2</sub> Comparison Table - LDR (250°)]] |

||

| − | |- |

||

| − | |} |

||

| + | ===[https://wiki.nanotech.ucsb.edu/w/images/7/72/PECVD1-cleaning.png Standard Cleaning Recipe (PECVD#1): "CF4/O2 Clean"]=== |

||

| − | === Amorphous Si (100%SiH<sub>4</sub> Ar He) === |

||

| + | Click the above link for a screenshot of the standard cleaning recipe, for which you will enter a custom time. The recipe is set up so that '''it will pop up a window for the cleaning time''' upon running the recipe - you do not need to edit the recipe before running it. |

||

| − | {| border="1" class="wikitable" style="border: 1px solid #D0E7FF; background-color:#ffffff; text-align:center;" |

||

| + | |||

| − | |- bgcolor="#D0E7FF" |

||

| + | =[[PECVD 2 (Advanced Vacuum)]]= |

||

| − | !width=350 align=center|90° |

||

| + | |||

| − | !width=350 align=center|250° |

||

| + | ===[https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=272916741 PECVD 2 Process Control Plots] - Plots of all process control data=== |

||

| − | |-align=left |

||

| + | |||

| − | | |

||

| + | ==SiO<sub>2</sub> deposition (PECVD #2)== |

||

| − | *[[Media:02-ICP-PECVD-a-Si_Film-90C.pdf|a-Si Deposition Recipe - 90°]] |

||

| + | |||

| − | | |

||

| + | *[https://docs.google.com/spreadsheets/d/1cYK-k669vf8YO2q2YCGa3gTdaDI3I3M-a9KR5RDlZWY/edit#gid= SiO<sub>2</sub><nowiki> [PECVD 2] New Standard Recipe</nowiki>] - "''STD SiO2 v2''" |

||

| − | *[[Media:01-ICP-PECVD-a-Si-Deposition_Recipe-250C.pdf|a-Si Deposition Recipe - 250°]] |

||

| + | *[https://docs.google.com/spreadsheets/d/1wCEcFj6ZMHR4QifngLXwz6dqbyf8hsVKu7bQbMS6EoA/edit#gid= SiO<sub>2</sub><nowiki> [PECVD 2] Old Standard Recipe</nowiki>] - "''STD SiO2''" |

||

| − | *[[Media:Amorphous_Silicon_Film_Deposition_using_12.5W_bias_on_SiO2-Si.pdf|Thick, Defects-free a-Si Film on SiO<sub>2</sub>/Si with a Lower Bias Power]] |

||

| + | *[https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=1313651154 SiO<sub>2</sub><nowiki> [PECVD 2] Current Process Control Data</nowiki>] |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/Old_Deposition_Data_-_2021-12-15#SiO2_deposition_.28PECVD_.232.29 SiO<sub>2</sub><nowiki> [PECVD 2] Historical Data</nowiki>] - Before Oct. 2021 |

||

| + | |||

| + | ==SiN deposition (PECVD #2)== |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/1JBXEfRGemFJK81RkHfxS0cTucb3viUL7hMGzmKRD5uU/edit#gid= Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] New Standard Recipe</nowiki>] - "''STD Si3N4 v3''" |

||

| + | *[https://docs.google.com/spreadsheets/d/1KS4HfhUJyYVep4H6CRAKpMRP5TA31F0qD-obQkKRnEI/edit#gid= Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Old Standard Recipe</nowiki>] - "''Nitride2''" |

||

| + | *[https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=773875841 Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Current Process Control Data</nowiki>] |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/Old_Deposition_Data_-_2021-12-15#SiN_deposition_.28PECVD_.232.29 Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Historical Data</nowiki>] - Before Oct. 2021 |

||

| + | |||

| + | ==Low-Stress SiN deposition (PECVD #2)== |

||

| + | ''Low-Stress Silicon Nitride, Si<sub>3</sub>N<sub>4</sub> (< ±100 MPa)'' |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/19VQ6ytYbZ5SsAiXzgWqwlyJUqgjWb8x_eyv7L8DvtwM/edit#gid= Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] New Standard Recipe</nowiki>] - "'' STD LS-Si3N4 v4 ''" |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/1DzzI7aE61R7c6gyk6cGBdm9FtGrApiNJ4AL90ll2C8k/edit#gid= Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Standard Recipe</nowiki>] - "'' Old LSNitride2 recipe ''" |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=584923738 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Current Process Control Data</nowiki>] |

||

| + | *[https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=203400760 Plots of Low-Stress Si<sub>3</sub>N<sub>4</sub> Process Control Data] |

||

| + | *[[Old Deposition Data - 2021-12-15#Low-Stress SiN deposition .28PECVD .232.29|Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Historical Data - Before Oct. 2021</nowiki>]] |

||

| + | *:''Old Versions of the recipe:'' |

||

| + | *:''[https://wiki.nanotech.ucsb.edu/wiki/images/a/a5/New_AdvPECVD-LS_Nitride2_300C_standard_recipe_LS_Nitride2_standard_recipe.pdf LS Nitride2 Standard Recipe 2014-5/9/2018]'' |

||

| + | *:''[https://wiki.nanotech.ucsb.edu/wiki/images/0/01/STD_LSNitride2_5-9-18.pdf STD LSNitride2 5/9/2018]'' |

||

| + | |||

| + | ==Amorphous-Si deposition (PECVD #2)== |

||

| + | |||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/images/9/9d/03-Amorphous-Si-PECVD-2.pdf Amorphous Si Deposition Recipe] |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/images/0/09/ASi_deposition_and_film_stress_using_AV_dep_tool.pdf Amorphous Si Film Characterization and Stress] |

||

| + | |||

| + | ==Standard Cleaning Procedure (PECVD #2)== |

||

| + | The cleaning procedure is very important in order to have consistent result on this tool and also to keep particulate count low. After each deposition you should clean the tool following instructions carefully. The clean is done in two steps: |

||

| + | |||

| + | #(If >29min dep time) Wet cleaning: Start cleaning by using a cleanroom wipe sprayed with DI. Wipe upper chamber sidewalls with it. Finish cleaning by using the cleanroom wipe sprayed with IPA & wiping again. |

||

| + | #Load the recipe for cleaning "STD CF<sub>4</sub>/O<sub>2</sub> Clean" (edit the recipe and change ONLY time of cleaning). Follow instructions regarding required time for cleaning. |

||

| + | |||

| + | ===[https://wiki.nanotech.ucsb.edu/w/images/3/34/PECVD2_photo_for_cleaning.png Standard Clean Recipe (PECVD#2): "STD CF4/O2 Clean"]=== |

||

| + | Click the above link for a screenshot of the standard cleaning recipe, for which you will enter a custom time. The recipe is set up so that it will pop up a window for the cleaning time upon running the recipe - you do not need to edit the recipe before running it. |

||

| + | |||

| + | |||

| + | '''Clean Times (PECVD#2''') |

||

| + | {| class="wikitable" |

||

| + | !Film Deposited |

||

| + | !Cleaning Time (Dry) |

||

|- |

|- |

||

| + | |SiO<sub>2</sub> |

||

| + | |1 min. clean for every 1 min. deposition |

||

| + | |- |

||

| + | |Si<sub>3</sub>N<sub>4</sub> |

||

| + | |1 min. clean for every 7 min of deposition |

||

| + | |- |

||

| + | |If > 29min total dep time |

||

| + | (Season + Dep) |

||

| + | |Wet Clean the Upper Lid/Chamber |

||

| + | DI water then Isopropyl Alcohol on chamber wall & portholes |

||

|} |

|} |

||

| + | |||

| + | =[[ICP-PECVD (Unaxis VLR)]]= |

||

| + | 2020-02: New recipes have been characterized for low particulate count and repeatability. Only staff-supplied recipes are allowed in the tool. Please follow the [[ICP-PECVD (Unaxis VLR)#Documentation|new procedures]] to ensure low particle counts in the chamber. |

||

| + | |||

| + | The system currently has '''Deuterated Silane (SiD<sub>4</sub>)''' installed - identical to the regular Silicon precursor SiH<sub>4</sub>, except that it significantly lowers optical absorption in the near-infrared due to shifted molecular vibrations/molecular weights. This gas is more expensive and thus more applicable to optical application than to general-purpose SiN films. |

||

| + | |||

| + | ==Process Control Data (Unaxis ICP-PECVD)== |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=417334948https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=417334948 ICP-PECVD Process Control Plots] - ''Plots of all Process Control data'' |

||

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=0 Low Deposition Rate SiO<sub>2</sub>] |

||

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1459210138 High Deposition Rate SiO<sub>2</sub>] |

||

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1670372499 Si<sub>3</sub>N<sub>4</sub>] |

||

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1517031044 Low Stress Si<sub>3</sub>N<sub>4</sub>] |

||

| + | |||

| + | ==Low Deposition Rate SiO<sub>2</sub> [ICP-PECVD]== |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/17ft9jrHcCFCp2830RsLwQq5lHuupWATXT91SreG8WYY/edit#gid=143856038 Low Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] - Standard Recipe</nowiki>] - "''SiO2 LDR250C''" |

||

| + | **[https://docs.google.com/spreadsheets/d/1wocoCPOOEDQcZbXJJNaZs1sr9dXBZpn1wUyglL8IQrI/edit#gid=1199123007 Old Recipe] - |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=0 Low Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] - Process Control Data</nowiki>] |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/Old_Deposition_Data_-_2021-12-15#SiO2_LDR_250C_Deposition_.28Unaxis_VLR.29 Low Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] - Historical Data</nowiki>] - before Oct. 2021 |

||

| + | |||

| + | ==High Deposition Rate SiO<sub>2</sub> [ICP-PECVD]== |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/13KUlUujEWSLOH54Ibd52YNJPZcAc7ELShI2RAqM6H-Y/edit#gid=117484667 High Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] - Standard Recipe</nowiki>] - "''SiO2 HDR250C''" |

||

| + | **[https://docs.google.com/spreadsheets/d/1OxHi5r9ifNvF8ODpIk6aoRevb4RdbbykwPVMm1g-yi4/edit#gid=1199123007 Old Recipe] |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1459210138 High Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] - Current Process Control Data</nowiki>] |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/Old_Deposition_Data_-_2021-12-15#SiO2_HDR_250C_Deposition_.28Unaxis_VLR.29 High Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] - Historical Data</nowiki>] |

||

| + | |||

| + | ==Si<sub>3</sub>N<sub>4</sub> [ICP-PECVD]== |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/1MffAE2S-Sga0o4botssPMi_P8C2ghxw4XiHwTnOn95Q/edit#gid=1111781219 Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] - Standard Recipe</nowiki>] - "''SiN 250C''" |

||

| + | **[https://docs.google.com/spreadsheets/d/1VrgS0cB2OcdZVTCnDAesgQCLRaAgEB_Iajc_OrhXOo0/edit#gid=1199123007 Old Recipe] |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1670372499 Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] - Current Process Control Data</nowiki>] |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/Old_Deposition_Data_-_2021-12-15#SiN_250C_deposition_.28Unaxis_VLR.29 Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] - Historical Data</nowiki>] - before Oct. 2021 |

||

| + | |||

| + | ==Low Stress Si<sub>3</sub>N<sub>4</sub> [ICP-PECVD]== |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/1JuQlCU-mozIUJx9z9aQdisIJyFhv1r9AWI8EWeOnsPo/edit#gid=82816489 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] - Standard Recipe</nowiki>] - "''SiN Low Stress 250C''" |

||

| + | **[https://docs.google.com/spreadsheets/d/1i2mE2K12EEulnCbO9KuU9PCcvHAmcGxTIXUF8x4IOWk/edit#gid=1199123007 Old Recipe] |

||

| + | |||

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1517031044 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] - Current Process Control Data</nowiki>] |

||

| + | |||

| + | ==Standard Cleaning Procedure [ICP-PECVD]== |

||

| + | You must edit the Post-Dep Clean recipe to correspond to your deposited thickness and material. See the [[ICP-PECVD (Unaxis VLR)#Documentation|Operating Procedure on the Unaxis Tool Page]] for details. |

||

| + | |||

| + | *SiNx etches at 20nm/min |

||

| + | *SiO<sub>2</sub> etches at 40nm/min |

||

| + | |||

| + | ===Standard Clean Recipe=== |

||

| + | ''To Be Added'' |

||

| + | |||

| + | ==General Recipe Notes (Unaxis VLR ICP-PECVD)== |

||

| + | |||

| + | *RF1 = Bias |

||

| + | *RF2 = ICP Power |

||

| + | *All recipes start with an Argon pre-clean with 0W bias (gentle), to improve adhesion/nucleation. |

||

| + | *Maximum SiO<sub>2</sub> Dep. thickness allowed: 800nm |

||

| + | **Above this thickness, you must run a chamber clean/season before depositing more onto your product wafer. |

||

Latest revision as of 10:28, 20 December 2023

Back to Vacuum Deposition Recipes.

PECVD 1 (PlasmaTherm 790)

PECVD 1 Process Control Plots - Plots of all process control data

SiO2 deposition (PECVD #1)

- SiO2 [PECVD 1] Current Process Control Data

- SiO2 [PECVD 1] Historical Data - Oct. 2021 and earlier

SiN deposition (PECVD #1)

- Si3N4 [PECVD 1] Standard Recipe

- Si3N4 [PECVD 1] Current Process Control Data

- Si3N4 [PECVD 1] Historical Data - Oct. 2021 and earlier

Low Stress Si3N4 (PECVD#1)

- Low Stress Si3N4 [PECVD 1] Standard Recipe

- Low Stress Si3N4 [PECVD 1] Historical Data - 2021-10 and earlier

Example of Si3N4 modified stress via. varying N2 flow. Refractive index is relatively constant (one outlier), and stress varies continuously from tensile to compressive. (Demis D. John 2011, Blumenthal Group)

Example of Si3N4 modified stress via. varying N2 flow. Refractive index is relatively constant (one outlier), and stress varies continuously from tensile to compressive. (Demis D. John 2011, Blumenthal Group)

SiOxNy deposition (PECVD #1)

- SiOxNy Standard Recipe

- SiOxNy Data 2014 - Rate, Index etc.

- SiOxNy1000A Thickness uniformity 2014

Standard Cleaning Procedure (PECVD #1)

The cleaning procedure is very important in order to have consistent result on this tool and also to keep particulate count low. After each deposition you should clean the tool following instructions carefully. The clean is done in two steps:

- Wet cleaning (start cleaning by using a cleanroom wipe sprayed with DI. Wipe chamber sidewalls with it. Finish cleaning by using the cleanroom wipe sprayed with IPA. )

- Load the recipe for cleaning "CF4/O2 Clean" (edit the recipe and change ONLY time of cleaning). Follow instructions regarding a required time for cleaning.

| Film Dep'd | Cleaning Time |

|---|---|

| SiO2 | TBD |

| Si3N4 | TBD |

| SiOxNy | Same as XYZ |

Standard Cleaning Recipe (PECVD#1): "CF4/O2 Clean"

Click the above link for a screenshot of the standard cleaning recipe, for which you will enter a custom time. The recipe is set up so that it will pop up a window for the cleaning time upon running the recipe - you do not need to edit the recipe before running it.

PECVD 2 (Advanced Vacuum)

PECVD 2 Process Control Plots - Plots of all process control data

SiO2 deposition (PECVD #2)

- SiO2 [PECVD 2] New Standard Recipe - "STD SiO2 v2"

- SiO2 [PECVD 2] Old Standard Recipe - "STD SiO2"

- SiO2 [PECVD 2] Current Process Control Data

- SiO2 [PECVD 2] Historical Data - Before Oct. 2021

SiN deposition (PECVD #2)

- Si3N4 [PECVD 2] New Standard Recipe - "STD Si3N4 v3"

- Si3N4 [PECVD 2] Old Standard Recipe - "Nitride2"

- Si3N4 [PECVD 2] Current Process Control Data

- Si3N4 [PECVD 2] Historical Data - Before Oct. 2021

Low-Stress SiN deposition (PECVD #2)

Low-Stress Silicon Nitride, Si3N4 (< ±100 MPa)

- Low Stress Si3N4 [PECVD 2] New Standard Recipe - " STD LS-Si3N4 v4 "

- Low Stress Si3N4 [PECVD 2] Standard Recipe - " Old LSNitride2 recipe "

- Low Stress Si3N4 [PECVD 2] Current Process Control Data

- Plots of Low-Stress Si3N4 Process Control Data

- Low Stress Si3N4 [PECVD 2] Historical Data - Before Oct. 2021

- Old Versions of the recipe:

- LS Nitride2 Standard Recipe 2014-5/9/2018

- STD LSNitride2 5/9/2018

Amorphous-Si deposition (PECVD #2)

Standard Cleaning Procedure (PECVD #2)

The cleaning procedure is very important in order to have consistent result on this tool and also to keep particulate count low. After each deposition you should clean the tool following instructions carefully. The clean is done in two steps:

- (If >29min dep time) Wet cleaning: Start cleaning by using a cleanroom wipe sprayed with DI. Wipe upper chamber sidewalls with it. Finish cleaning by using the cleanroom wipe sprayed with IPA & wiping again.

- Load the recipe for cleaning "STD CF4/O2 Clean" (edit the recipe and change ONLY time of cleaning). Follow instructions regarding required time for cleaning.

Standard Clean Recipe (PECVD#2): "STD CF4/O2 Clean"

Click the above link for a screenshot of the standard cleaning recipe, for which you will enter a custom time. The recipe is set up so that it will pop up a window for the cleaning time upon running the recipe - you do not need to edit the recipe before running it.

Clean Times (PECVD#2)

| Film Deposited | Cleaning Time (Dry) |

|---|---|

| SiO2 | 1 min. clean for every 1 min. deposition |

| Si3N4 | 1 min. clean for every 7 min of deposition |

| If > 29min total dep time

(Season + Dep) |

Wet Clean the Upper Lid/Chamber

DI water then Isopropyl Alcohol on chamber wall & portholes |

ICP-PECVD (Unaxis VLR)

2020-02: New recipes have been characterized for low particulate count and repeatability. Only staff-supplied recipes are allowed in the tool. Please follow the new procedures to ensure low particle counts in the chamber.

The system currently has Deuterated Silane (SiD4) installed - identical to the regular Silicon precursor SiH4, except that it significantly lowers optical absorption in the near-infrared due to shifted molecular vibrations/molecular weights. This gas is more expensive and thus more applicable to optical application than to general-purpose SiN films.

Process Control Data (Unaxis ICP-PECVD)

- ICP-PECVD Process Control Plots - Plots of all Process Control data

- Low Deposition Rate SiO2

- High Deposition Rate SiO2

- Si3N4

- Low Stress Si3N4

Low Deposition Rate SiO2 [ICP-PECVD]

- Low Deposition Rate SiO2 [ICP-PECVD] - Standard Recipe - "SiO2 LDR250C"

- Low Deposition Rate SiO2 [ICP-PECVD] - Process Control Data

- Low Deposition Rate SiO2 [ICP-PECVD] - Historical Data - before Oct. 2021

High Deposition Rate SiO2 [ICP-PECVD]

- High Deposition Rate SiO2 [ICP-PECVD] - Standard Recipe - "SiO2 HDR250C"

- High Deposition Rate SiO2 [ICP-PECVD] - Current Process Control Data

- High Deposition Rate SiO2 [ICP-PECVD] - Historical Data

Si3N4 [ICP-PECVD]

- Si3N4 [ICP-PECVD] - Standard Recipe - "SiN 250C"

- Si3N4 [ICP-PECVD] - Current Process Control Data

- Si3N4 [ICP-PECVD] - Historical Data - before Oct. 2021

Low Stress Si3N4 [ICP-PECVD]

- Low Stress Si3N4 [ICP-PECVD] - Standard Recipe - "SiN Low Stress 250C"

Standard Cleaning Procedure [ICP-PECVD]

You must edit the Post-Dep Clean recipe to correspond to your deposited thickness and material. See the Operating Procedure on the Unaxis Tool Page for details.

- SiNx etches at 20nm/min

- SiO2 etches at 40nm/min

Standard Clean Recipe

To Be Added

General Recipe Notes (Unaxis VLR ICP-PECVD)

- RF1 = Bias

- RF2 = ICP Power

- All recipes start with an Argon pre-clean with 0W bias (gentle), to improve adhesion/nucleation.

- Maximum SiO2 Dep. thickness allowed: 800nm

- Above this thickness, you must run a chamber clean/season before depositing more onto your product wafer.