Difference between revisions of "Plasma Clean (Gasonics 2000)"

Jump to navigation

Jump to search

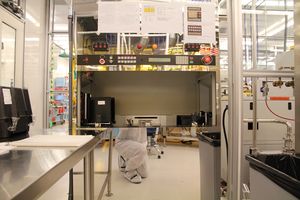

(Created page with "{{tool|{{PAGENAME}} |picture=Gasonics.jpg |type = Dry Etch |super= Mike Silva |phone=(805)839-3918x219 |location=Bay 5 |email=silva@ece.ucsb.edu |description = Aura 2000-LL Downs…") |

(mention tool removed, link to YES and Pan1 Ashing) |

||

| Line 9: | Line 9: | ||

|manufacturer = Gasonics |

|manufacturer = Gasonics |

||

|materials = |

|materials = |

||

| − | }} |

+ | }} |

| + | '''This tool has been removed. The [[Plasma Clean (YES EcoClean)|YES EcoClean]] and [[ICP Etch 1 (Panasonic E646V)|Panasonic ICP #1 Ashing]] are the process replacements.''' ''-- DJ 2023'' |

||

| ⚫ | |||

| + | |||

| ⚫ | |||

The Aura 2000 system is a microwave downstream asher used for the removal of resist and other organic materials. Samples are loaded onto 8” carrier wafers into the system. Samples can be heated from 100C to above 350C by heat lamps, while being exposed to microwave-cracked oxygen to remove organic materials. The microwave excitation of the oxygen is done downstream from the chamber and the reactive oxygen flows through a showerhead to expose the sample, thus completely eliminating ion bombardment. Resist etch rates of several microns per minute can be achieved and is also effective on fluorine and chlorine plasma exposed resist. |

The Aura 2000 system is a microwave downstream asher used for the removal of resist and other organic materials. Samples are loaded onto 8” carrier wafers into the system. Samples can be heated from 100C to above 350C by heat lamps, while being exposed to microwave-cracked oxygen to remove organic materials. The microwave excitation of the oxygen is done downstream from the chamber and the reactive oxygen flows through a showerhead to expose the sample, thus completely eliminating ion bombardment. Resist etch rates of several microns per minute can be achieved and is also effective on fluorine and chlorine plasma exposed resist. |

||

Latest revision as of 12:12, 23 February 2024

| ||||||||||||||||||||

This tool has been removed. The YES EcoClean and Panasonic ICP #1 Ashing are the process replacements. -- DJ 2023

About

The Aura 2000 system is a microwave downstream asher used for the removal of resist and other organic materials. Samples are loaded onto 8” carrier wafers into the system. Samples can be heated from 100C to above 350C by heat lamps, while being exposed to microwave-cracked oxygen to remove organic materials. The microwave excitation of the oxygen is done downstream from the chamber and the reactive oxygen flows through a showerhead to expose the sample, thus completely eliminating ion bombardment. Resist etch rates of several microns per minute can be achieved and is also effective on fluorine and chlorine plasma exposed resist.