Difference between revisions of "Thermal Processing Recipes"

Jump to navigation

Jump to search

m (→1050°C Wet Oxidation: image adjust) |

m (→1050°C Dry Oxidation: correction to pressures) |

||

| Line 8: | Line 8: | ||

==== 1050°C Dry Oxidation ==== |

==== 1050°C Dry Oxidation ==== |

||

| − | * Partial Pressure = 1. |

+ | * Partial Pressure = 1.12 |

* <100>, 1050°C, 10Å Native Oxide, no dopants |

* <100>, 1050°C, 10Å Native Oxide, no dopants |

||

[[File:TyStar Thermal Oxidations - DryOx 1050°C 2018-04-09.png|frameless|300x300px]] |

[[File:TyStar Thermal Oxidations - DryOx 1050°C 2018-04-09.png|frameless|300x300px]] |

||

==== 1050°C Wet Oxidation ==== |

==== 1050°C Wet Oxidation ==== |

||

| − | * Partial Pressure = 1. |

+ | * Partial Pressure = 1.09 |

* <100>, 1050°C, 10Å Native Oxide, no dopants |

* <100>, 1050°C, 10Å Native Oxide, no dopants |

||

{| |

{| |

||

Revision as of 12:20, 9 April 2018

Tystar 8300

Thermal Oxidation of Silicon

Online calculators for thermal oxidation can be used to estimate the oxidation time for a desired oxidation thickness. Please see the Calculators + Utilities page for links to these oxidation calculators.

Using the Stanford Leland Jr. "Advanced Silicon Thermal Oxide Thickness Calculator", we have determined the following simulation parameters to predict oxidation times.

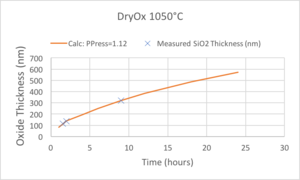

1050°C Dry Oxidation

- Partial Pressure = 1.12

- <100>, 1050°C, 10Å Native Oxide, no dopants

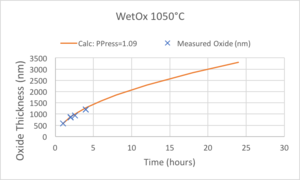

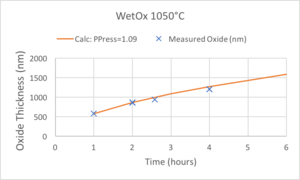

1050°C Wet Oxidation

- Partial Pressure = 1.09

- <100>, 1050°C, 10Å Native Oxide, no dopants

|

|

|---|

Wafer Substrate Bonding

Numerous research groups perform wafer bonding using either the Suss Wafer Bonder or a custom graphite fixture and any one of numerous ovens, such as the N2-purged Wafer Bonding Furnace (with glove box) or N2-purged Blue M oven.

The EVG Plasma Activation system and Goniometer allow for surface prep/inspection prior to bonding.