Difference between revisions of "Holographic Lith/PL Setup (Custom)"

(link to PL system page) |

(cusotme system, updated supervisor) |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 2: | Line 2: | ||

|picture=Holograph.jpg |

|picture=Holograph.jpg |

||

|type = Lithography |

|type = Lithography |

||

| − | |super= |

+ | |super= Demis D. John |

| − | |phone=(805) 839-5689 |

||

|location=Bay 6 |

|location=Bay 6 |

||

| + | |description = Custom Interference Lithography |

||

| − | |email=Ningcao@ece.ucsb.edu |

||

| − | | |

+ | |manufacturer = Custom-Built Free-Space Optics |

| − | |manufacturer = Kimmon |

||

|toolid=35 |

|toolid=35 |

||

}} |

}} |

||

| − | = |

+ | ==About== |

The interference lithography system (aka. Holography) at UCSB uses a 15mW, single-mode, 325 nm HeCd laser that is filtered and expanded by pinhole filters to produce the large area exposure beam. The system uses a simple mirror configuration with a fixed 90 degree angle between the mirror and sample. The entire mirror/sample assembly is rotated in 0.1 degree increments to change the grating pitch from ~ 200 nm to ~ 280 nm (35 to 55 degrees) over an ~ 2 cm x 2 cm exposure area. |

The interference lithography system (aka. Holography) at UCSB uses a 15mW, single-mode, 325 nm HeCd laser that is filtered and expanded by pinhole filters to produce the large area exposure beam. The system uses a simple mirror configuration with a fixed 90 degree angle between the mirror and sample. The entire mirror/sample assembly is rotated in 0.1 degree increments to change the grating pitch from ~ 200 nm to ~ 280 nm (35 to 55 degrees) over an ~ 2 cm x 2 cm exposure area. |

||

| − | [[Lithography Recipes#Chemicals Stocked .2B Datasheets|THMR-3600HP]] resist spin-coated to ~ |

+ | [https://wiki.nanofab.ucsb.edu/w/images/3/33/XHRiC-Anti-Reflective-Coating.pdf XHRiC] bottom anti-reflection coating (BARC) & [[Lithography Recipes#Chemicals Stocked .2B Datasheets|THMR-3600HP]] imaging resist spin-coated to ~80 nm thickness is used for grating exposure. 2-D gratings can be formed by rotating the sample and doing multiple exposures. Total exposure times are controlled by a manual shutter and are generally several minutes in length. |

A photoluminescence measurement setup is co-located on the optical table. Please see the page for the PL system for more info: |

A photoluminescence measurement setup is co-located on the optical table. Please see the page for the PL system for more info: |

||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| + | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| + | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| + | *Max sample size: ~1.5 inch square uniform exposure area |

||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| + | *Manual optics alignment. |

||

| + | *1-D and 2-D gratings possible, see recipes below. |

||

| + | |||

| + | ==Recipes== |

||

| + | |||

| + | *[[Lithography Recipes#Holography%20Recipes|Lithography Recipes > Holography Recipes]] - developed recipes for 1D (line/space) and 2D (pillars) gratings. |

||

Latest revision as of 20:48, 26 September 2023

|

About

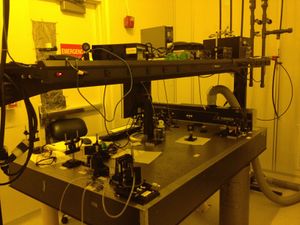

The interference lithography system (aka. Holography) at UCSB uses a 15mW, single-mode, 325 nm HeCd laser that is filtered and expanded by pinhole filters to produce the large area exposure beam. The system uses a simple mirror configuration with a fixed 90 degree angle between the mirror and sample. The entire mirror/sample assembly is rotated in 0.1 degree increments to change the grating pitch from ~ 200 nm to ~ 280 nm (35 to 55 degrees) over an ~ 2 cm x 2 cm exposure area.

XHRiC bottom anti-reflection coating (BARC) & THMR-3600HP imaging resist spin-coated to ~80 nm thickness is used for grating exposure. 2-D gratings can be formed by rotating the sample and doing multiple exposures. Total exposure times are controlled by a manual shutter and are generally several minutes in length.

A photoluminescence measurement setup is co-located on the optical table. Please see the page for the PL system for more info:

Detailed Specifications

- 15 mW single TEM mode HeCd laser (Kimmon)

- Max sample size: ~1.5 inch square uniform exposure area

- ~2 cm x 2 cm uniform exposure area

- Several-minute exposure times (manual shutter)

- Grating period adjustable from ~200 to ~280 nm with rotation stage

- Manual optics alignment.

- 1-D and 2-D gratings possible, see recipes below.

Recipes

- Lithography Recipes > Holography Recipes - developed recipes for 1D (line/space) and 2D (pillars) gratings.