Difference between revisions of "Stepper 3 (ASML DUV)"

(→Troubleshooting and Recovery: link to "ASML 5500: Choose Marks for Prealignment") |

m (moved/updated "service provider") |

||

| (17 intermediate revisions by 2 users not shown) | |||

| Line 2: | Line 2: | ||

|picture=ASML.jpg |

|picture=ASML.jpg |

||

|type = Lithography |

|type = Lithography |

||

| − | |super= |

+ | |super= Demis D. John |

| ⚫ | |||

| − | |phone=(805)839-2268 |

||

| ⚫ | |||

| − | |email=thibeault@ece.ucsb.edu |

||

|description = ASML PAS 5500/300 DUV Stepper |

|description = ASML PAS 5500/300 DUV Stepper |

||

| − | |manufacturer = |

+ | |manufacturer = [http://www.asml.com ASML] |

| + | |ToolType = Lithography |

||

| + | |recipe = Lithography |

||

|materials = |

|materials = |

||

|toolid=51 |

|toolid=51 |

||

}} |

}} |

||

| − | = |

+ | =About= |

| − | The ASML 5500 stepper is a 248nm DUV stepper for imaging dense features down to below 200nm and isolated line structures down to below 150nm. Overlay accuracy is better than 30nm. |

+ | The ASML 5500 stepper is a 248nm DUV stepper for imaging dense features down to below 200nm and isolated line structures down to below 150nm. Overlay accuracy is better than 30nm. |

| + | |||

| + | The system is configured for 4” wafers and, with staff support, mounted pieces down to 14mm in size can be exposed using a 4” wafer as a carrier. The system is designed for high throughput, so shooting multiple 4" wafers is extremely fast. Additionally, exposure jobs are highly programmable, allowing for very flexible exposures of multiple aligned patterns from multiple masks in a single session, allowing for process optimization of large vs. small features in a single lithography. |

||

The full field useable exposure area is limited to the intersection of a 31mm diameter circle and a rectangle of dimensions 22mm x 27mm. See the [[ASML 5500 Mask Making Guidelines|Mask Making Guidelines page]] for more info on exposure field sizes and how to order your mask plates. |

The full field useable exposure area is limited to the intersection of a 31mm diameter circle and a rectangle of dimensions 22mm x 27mm. See the [[ASML 5500 Mask Making Guidelines|Mask Making Guidelines page]] for more info on exposure field sizes and how to order your mask plates. |

||

| − | Resists Used (see [https://www.nanotech.ucsb.edu/wiki/index.php/Lithography_Recipes#Photolithography_Recipes PhotoLith. Recipes] for |

+ | Resists Used (see [https://www.nanotech.ucsb.edu/wiki/index.php/Lithography_Recipes#Photolithography_Recipes PhotoLith. Recipes] for full process info): |

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| − | * PMGI: Underlayer |

||

| ⚫ | |||

| ⚫ | |||

| + | |||

| ⚫ | |||

| + | *PMGI/LOL1000/LOL2000 - Underlayers |

||

AZ300MIF Developer for all processes |

AZ300MIF Developer for all processes |

||

| − | = |

+ | =Process Information= |

| − | *[https://www.nanotech.ucsb.edu/wiki/index.php/Lithography_Recipes#Photolithography_Recipes Process Page] |

+ | *[https://www.nanotech.ucsb.edu/wiki/index.php/Lithography_Recipes#Photolithography_Recipes '''Process Recipes Page'''] '''> "Stepper 3"''' - ''Established recipes and corresponding linewidths, photoresists etc.'' |

| + | *Sample size: 100 mm wafers with SEMI std. major flat |

||

| − | |||

| + | **''Piece-parts process is possible but difficult - contact staff for info'' |

||

| ⚫ | |||

| + | *Alignment Accuracy: < 50 nm |

||

| − | * [http://www.asml.com ASML] |

||

| + | *Minimum Feature Size: ≤150 nm isolated lines, ≤200 nm dense patterns |

||

| + | *Maximum Wafer Bow: approx. 100 µm. (4-inch diam.) |

||

| + | **''Near this value, and the job may fail or lose the wafer inside the machine due to wafer vacuum error.'' |

||

| + | *[[ASML Stepper 3 - UCSB Test Reticles|UCSB Test Reticles - Alignment Markers, Resolution Testing etc.]] |

||

=Operating Procedures= |

=Operating Procedures= |

||

| − | * [[media:ASML Job Set-Up Guide v2.pdf|Job Programming - Full]] |

||

| − | * [[media:ASML Job Set-Up Guide simple v1.pdf|Job Programming- Simplified -Full Wafers]] |

||

| ⚫ | |||

| + | *[[ASML Stepper 3 Standard Operating Procedure|Standard Operating Procedures]] |

||

| ⚫ | |||

| + | **''Exposing wafers, loading reticles, focus/exposure matrix'' |

||

| ⚫ | |||

| + | *[//www.nanotech.ucsb.edu/wiki/images/f/f7/ASML_Job_Set-Up_Guide_v2.pdf Job Programming - Full] |

||

| ⚫ | |||

| + | *[//www.nanotech.ucsb.edu/wiki/images/c/cd/ASML_Job_Set-Up_Guide_simple_v1.pdf Job Programming- Simplified -Full Wafers] |

||

| ⚫ | |||

| + | |||

| ⚫ | |||

| + | |||

| + | *[[ASML Stepper 3 Error Recovery, Troubleshooting and Calibration|Error Recovery, Troubleshooting and Calibration]] |

||

| + | **''Common errors/System Warnings, Wafer Handler Reset, System Calibration Verification'' |

||

| + | |||

| ⚫ | |||

| ⚫ | |||

| + | |||

| ⚫ | |||

| + | *[http://www.asml.com ASML] - ASML performs quarterly periodic maintenance and provides on-demand support. |

||

| − | * [[ASML 5500: Recovering from a Typo in Reticle ID]] |

||

| − | ** ''If you ran a job and got "Reticle Not Present" due to a typo in your job/layer/image's reticle ID.'' |

||

| − | * [[ASML 5500: Choose Marks for Prealignment]] |

||

| − | ** ''If your job aborted with "Alignment failure" on the P-Chuck, because it couldn't find the alignment marks, this is how to edit your job to use different alignment marks.'' |

||

Revision as of 17:34, 21 November 2019

| |||||||||||||||||||||

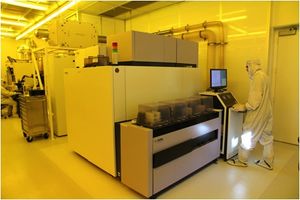

About

The ASML 5500 stepper is a 248nm DUV stepper for imaging dense features down to below 200nm and isolated line structures down to below 150nm. Overlay accuracy is better than 30nm.

The system is configured for 4” wafers and, with staff support, mounted pieces down to 14mm in size can be exposed using a 4” wafer as a carrier. The system is designed for high throughput, so shooting multiple 4" wafers is extremely fast. Additionally, exposure jobs are highly programmable, allowing for very flexible exposures of multiple aligned patterns from multiple masks in a single session, allowing for process optimization of large vs. small features in a single lithography.

The full field useable exposure area is limited to the intersection of a 31mm diameter circle and a rectangle of dimensions 22mm x 27mm. See the Mask Making Guidelines page for more info on exposure field sizes and how to order your mask plates.

Resists Used (see PhotoLith. Recipes for full process info):

- UV210-0.3 - Positive: 300nm nominal thickness

- UV6-0.8 - Positive: 800nm nominal thickness

- UV26-2.5 - Positive: 2.5um nominal thickness

- UVN2300-0.5 - Negative: 500nm nominal thickness

- DUV42P-6/DS-K101 - Bottom Anti-Reflective Coatings “BARC”

- PMGI/LOL1000/LOL2000 - Underlayers

AZ300MIF Developer for all processes

Process Information

- Process Recipes Page > "Stepper 3" - Established recipes and corresponding linewidths, photoresists etc.

- Sample size: 100 mm wafers with SEMI std. major flat

- Piece-parts process is possible but difficult - contact staff for info

- Alignment Accuracy: < 50 nm

- Minimum Feature Size: ≤150 nm isolated lines, ≤200 nm dense patterns

- Maximum Wafer Bow: approx. 100 µm. (4-inch diam.)

- Near this value, and the job may fail or lose the wafer inside the machine due to wafer vacuum error.

- UCSB Test Reticles - Alignment Markers, Resolution Testing etc.

Operating Procedures

- Standard Operating Procedures

- Exposing wafers, loading reticles, focus/exposure matrix

- Job Programming - Full

- Job Programming- Simplified -Full Wafers

- ASML 5500 Mask Making Guidelines

Troubleshooting and Recovery

- Error Recovery, Troubleshooting and Calibration

- Common errors/System Warnings, Wafer Handler Reset, System Calibration Verification

- ASML 5500: Recovering from an Error/Wafer Retrieval

- How to abort the job and recover your wafer.

Service Provider

- ASML - ASML performs quarterly periodic maintenance and provides on-demand support.