Difference between revisions of "Automated Coat/Develop System (S-Cubed Flexi)"

Jump to navigation

Jump to search

(Added ToolTemplate - tool type and recepe) |

(added PR's and links to recipes) |

||

| Line 17: | Line 17: | ||

=Detailed Specifications= |

=Detailed Specifications= |

||

| − | * |

+ | *Wafer Size: 100mm (150mm possible but not set up) |

| + | *PR Coating Properties: |

||

| ⚫ | |||

| + | **Uniformity < 1.0% |

||

| ⚫ | |||

| + | **< 100 particles on 100mm wafer |

||

| ⚫ | |||

| ⚫ | |||

| + | **UV6-0.8 |

||

| + | **DS-K101-304 |

||

| + | **PMMA |

||

| + | **PMGI SF11 |

||

| + | **PMGI SF5 |

||

| ⚫ | |||

| + | **EBR100 |

||

| ⚫ | |||

| + | **AZ 300 MiF |

||

=Process Information= |

=Process Information= |

||

| + | *Recipe Page for S-Cubed Coater: [[Lithography Recipes#Automated%20Coat.2FDevelop%20System%20Recipes%20.28S-Cubed%20Flexi.29|Lithography Recipes > Automated Coat/Develop System Recipes (S-Cubed Flexi]]) |

||

| − | * TBD |

||

=Operating Procedures= |

=Operating Procedures= |

||

| + | *''To Be Added'' |

||

| − | * TBD |

||

Revision as of 16:00, 8 October 2019

| ||||||||||||||||||||

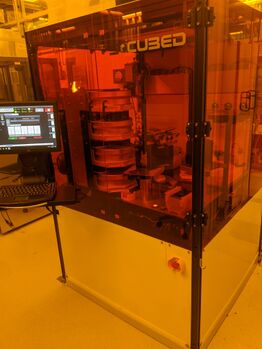

About

To Be Added

Detailed Specifications

- Wafer Size: 100mm (150mm possible but not set up)

- PR Coating Properties:

- Uniformity < 1.0%

- < 100 particles on 100mm wafer

- Photoresists/Underlayers Available:

- UV6-0.8

- DS-K101-304

- PMMA

- PMGI SF11

- PMGI SF5

- Solvents Available:

- EBR100

- Developers Available:

- AZ 300 MiF

Process Information

- Recipe Page for S-Cubed Coater: Lithography Recipes > Automated Coat/Develop System Recipes (S-Cubed Flexi)

Operating Procedures

- To Be Added