Difference between revisions of "Wafer Bonder (SUSS SB6-8E)"

Jump to navigation

Jump to search

(Created page with "{{tool|{{PAGENAME}} |picture=WaferBonder.jpg |type = Lithography |super= Don Freeborn |phone=(805)839-3918x216 |location=Bay 7 |email=freeborn@ece.ucsb.edu |description = Karl Su…") |

|||

| Line 1: | Line 1: | ||

{{tool|{{PAGENAME}} |

{{tool|{{PAGENAME}} |

||

|picture=WaferBonder.jpg |

|picture=WaferBonder.jpg |

||

| − | |type = |

+ | |type = Packaging |

|super= Don Freeborn |

|super= Don Freeborn |

||

|phone=(805)839-3918x216 |

|phone=(805)839-3918x216 |

||

Revision as of 07:02, 11 July 2012

|

About

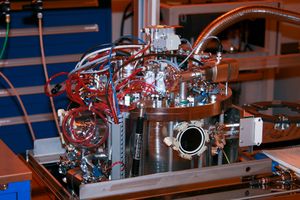

This is Karl-Suss model SB-6 substrate bonder. Wafer bonding of pieces to 6” wafers can be done at pressures from 5e-5 to 3e3 mBar and from 50°C to 550°C. This tool mates with the Karl-Suss MA-6 aligner to allow for aligned bonding. Forces up to 20 kN for a 150 mm wafer size are available. The system supports thermal compression as well as anodic bonding (up to 2000 V). The system is computer controlled with a windows environment allowing for multiple recipe steps and saving of recipes and data. The system is configured for manual loading of wafers.

Detailed Specifications

- Wafer bonding from 50°C to 550°C, +/- 5 degrees accuracy, +/- 3% uniformity

- Upper and lower heating of samples

- 5e-5 to 3e3 Torr environment bonding pressure, with Nitrogen

- Sample size: pieces to 6” wafers, aligned bonding by using MA/BA-6 aligner

- Anodic bonding to 2000 V

- Windows-based computer control