Difference between revisions of "Wafer Bonder (Logitech WBS7)"

(→About: links to applicable tools) |

Millerski w (talk | contribs) (Updated SOP) |

||

| (2 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | {{ |

+ | {{tool2|{{PAGENAME}} |

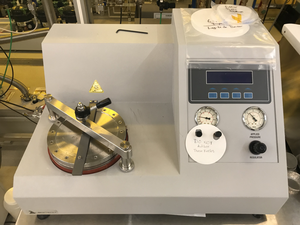

|picture=Logitech_WSBU-6_Wafer_Bonder_-_photo_-_800px.png |

|picture=Logitech_WSBU-6_Wafer_Bonder_-_photo_-_800px.png |

||

|type = Thermal Processing |

|type = Thermal Processing |

||

|super= Bill Millerski |

|super= Bill Millerski |

||

| + | |super2= Don Freeborn |

||

|phone=(805)839-3918x216 |

|phone=(805)839-3918x216 |

||

|location=Bay 5 |

|location=Bay 5 |

||

| Line 29: | Line 30: | ||

==Operation Procedures== |

==Operation Procedures== |

||

| + | |||

| + | * [https://wiki.nanofab.ucsb.edu/w/images/7/7a/Logitech_Wafer_Bonder_Operating_Instructions.pdf Wafer Bonder Operation Procedure] |

||

==Recipes== |

==Recipes== |

||

| + | ''Known working recipes for bonding wafers, and tips & tricks for developing your own:'' |

||

*Recipes > Packaging Recipes > [https://wiki.nanotech.ucsb.edu/w/index.php?title=Packaging_Recipes#Wafer_Bonder_.28Logitech_WBS7.29 Wafer Bonder (Logitech WBS7)] |

*Recipes > Packaging Recipes > [https://wiki.nanotech.ucsb.edu/w/index.php?title=Packaging_Recipes#Wafer_Bonder_.28Logitech_WBS7.29 Wafer Bonder (Logitech WBS7)] |

||

Latest revision as of 14:50, 30 October 2023

| ||||||||||||||||||||||||||

About

This tool is most often used for bonding samples to Silicon carrier wafers with CrystalBond wax.

This mounting method can be used for

- securing smaller parts for use on 100mm tools (such as the CMP)

- providing a carrier wafer for through-etching of Silicon wafers on the Bosch Etcher

- for dicing

- for lithography

A user can place the two wafers to be bonded in contact, with the adhesive in between (such as wax, photoresist etc.). A rubber membrane is lowered on top, creating a small vacuum chamber. The tool can then be programmed to heat the wafers and melt the wax/cure the adhesive, while vacuum is pulled in the chamber, which pulls the rubber membrane down onto the top wafer. This flattens the bond and evacuates bubbles from between the wafers, providing a planar bond.

We also have recipes for spin-coating the crystalbond wax, allowing for a uniform coating of the adhesive wax.

Detailed Specifications

- Substrate Size: 4"-6"

- Temperature Range: 20°C-188°C

Operation Procedures

Recipes

Known working recipes for bonding wafers, and tips & tricks for developing your own:

- Recipes > Packaging Recipes > Wafer Bonder (Logitech WBS7)