Tube Furnace Wafer Bonding (Thermco)

Jump to navigation

Jump to search

The printable version is no longer supported and may have rendering errors. Please update your browser bookmarks and please use the default browser print function instead.

|

About

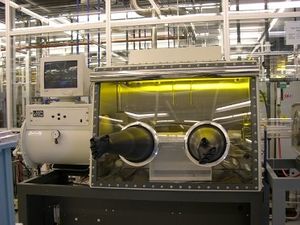

This wafer fusion furnace is a custom built unit designed for the fusion of different material types (such InP and Si) to create new heterostructures for novel electronic and optoelectronic devices. Custom made bonding fixtures are loaded into the furnace through a purged glove-box that is oxygen free to below 10 ppm with a dew point near -80°C. The furnace is nitrogen purged and can operate up from 200°C to 1200°C. Many different materials are allowed and maximum temperature is dependent on the materials themselves, to avoid contamination of the furnace.

Detailed Specifications

- Temperatures 200°C to 1200°C

- 4 inch diameter furnace

- Nitrogen ambient at atmospheric pressure

- Oxygen control in glove box to less than 10 ppm

- Dew point near -80°C

- Custom bonding fixtures of various materials allowed