Difference between revisions of "Thermal Processing Recipes"

m (link to new goniometer page) |

(→Tystar 8300: added wafer cleaning) |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

==[[Tube Furnace (Tystar 8300)|Tystar 8300]]== |

==[[Tube Furnace (Tystar 8300)|Tystar 8300]]== |

||

| − | === |

+ | ===Thermal Oxidation of Silicon - Calculating Oxidation Times=== |

Online calculators for thermal oxidation can be used to estimate the oxidation time for a desired oxidation thickness. |

Online calculators for thermal oxidation can be used to estimate the oxidation time for a desired oxidation thickness. |

||

Please see the [[Calculators + Utilities]] page for links to these oxidation calculators. |

Please see the [[Calculators + Utilities]] page for links to these oxidation calculators. |

||

| Line 7: | Line 7: | ||

Using the [http://www.lelandstanfordjunior.com/thermaloxide.html Stanford Leland Jr. "Advanced Silicon Thermal Oxide Thickness Calculator"], we have determined the following simulation parameters (“partial pressure” in particular) to predict oxidation times. Please note, however, that doping level, impurity concentration and other factors can alter these calibrations, so you may need to calibrate the ''Partial Pressure'' yourself if you need higher accuracy. |

Using the [http://www.lelandstanfordjunior.com/thermaloxide.html Stanford Leland Jr. "Advanced Silicon Thermal Oxide Thickness Calculator"], we have determined the following simulation parameters (“partial pressure” in particular) to predict oxidation times. Please note, however, that doping level, impurity concentration and other factors can alter these calibrations, so you may need to calibrate the ''Partial Pressure'' yourself if you need higher accuracy. |

||

| + | A simpler but less accurate oxidation calculator can be found at the [https://cleanroom.byu.edu/oxidetimecalc/ BYU Thermal Oxidation Calculator]. |

||

| ⚫ | |||

| − | + | === Wafer Cleaning === |

|

| + | For Tube #2, Silicon wafer cleaning, the following process is recommended: |

||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| + | # If brand new wafers, they should be already relatively clean. Otherwise Acetone/ISO clean might be needed to remove particles - optional |

||

| ⚫ | |||

| + | # Use [[Wet Benches#Wafer Toxic Corrosive Benches|Bay 4 toxic corrosive bench]] to submerge wafers for 20min in PureStrip @ 60°C. Replenish if needed, since PureStrip degrades after a few days at 60°C. |

||

| ⚫ | |||

| + | # QDR - rinse. |

||

| ⚫ | |||

| + | # Transport to Bay 5 HF bench (keep in water - optional) - use Chemical Transport Container. |

||

| ⚫ | |||

| + | # Submerge in HF for 10min. |

||

| + | # Rinse in DI 3x at HF bench. Pure HF goes down special drain, while rinse water can go down normal drain. |

||

| + | # Dry with Nitrogen gun OR SRD "Spin Rinse Dryer" at Bay 5. |

||

| + | # Ready to load into Tystar quartz boats, run recipe on Tystar. |

||

| − | === |

+ | ===Thermal Oxidation Recipes=== |

| + | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| + | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| + | |||

| ⚫ | |||

| + | |||

| ⚫ | |||

| ⚫ | |||

| + | |||

| ⚫ | |||

| + | |||

| + | ====1050°C Wet Oxidation==== |

||

| + | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| + | |||

| ⚫ | |||

| + | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

{| |

{| |

||

| − | ![[File:TyStar_Thermal_Oxidations_-_WetOx_1050°C_2018-04-09.png|alt=plot of Measurements and Curve-Fitting for 1050°C Wet oxidations.|none|thumb|300x300px|Measurements and Curve-Fitting for 1050°C Wet oxidations.]] |

+ | ![[File:TyStar_Thermal_Oxidations_-_WetOx_1050°C_2018-04-09.png|alt=plot of Measurements and Curve-Fitting for 1050°C Wet oxidations.|none|thumb|300x300px|Measurements and Curve-Fitting for 1050°C Wet oxidations. '''''(Demis D. John, 2017-12)''''']] |

![[File:TyStar_Thermal_Oxidations_-_WetOx_1050°C_2018-04-09_zoom.png|alt=plot of Zoom-in on Measurements and Curve-Fitting for 1050°C Wet oxidations.|none|thumb|300x300px|Zoom-in on Measurements and Curve-Fitting for 1050°C Wet oxidations.]] |

![[File:TyStar_Thermal_Oxidations_-_WetOx_1050°C_2018-04-09_zoom.png|alt=plot of Zoom-in on Measurements and Curve-Fitting for 1050°C Wet oxidations.|none|thumb|300x300px|Zoom-in on Measurements and Curve-Fitting for 1050°C Wet oxidations.]] |

||

|} |

|} |

||

| − | ==== |

+ | ====AlGaAs Oxidation==== |

A recipe is available on Tube #1 for thermal oxidation of AlGaAs layers, at much lower temperatures than Tubes #2 & #3. There are special procedures for running this lower-temp. oxidation at shorter times, please contact [[Tony Bosch]] or the NanoFab process Group for more information. |

A recipe is available on Tube #1 for thermal oxidation of AlGaAs layers, at much lower temperatures than Tubes #2 & #3. There are special procedures for running this lower-temp. oxidation at shorter times, please contact [[Tony Bosch]] or the NanoFab process Group for more information. |

||

==Wafer Substrate Bonding== |

==Wafer Substrate Bonding== |

||

| − | === |

+ | ===Direct Bonding=== |

Numerous research groups perform direct wafer bonding (of various materials) using either the [[Wafer Bonder (SUSS SB6-8E)|Suss Wafer Bonder]], or a custom graphite fixture in conjunction with any one of [[Thermal Processing|numerous ovens]], such as the N2-purged [[Tube Furnace Wafer Bonding (Thermco)|Wafer Bonding Furnace]] (with glove box) or N2-purged [[High Temp Oven (Blue M)|Blue M oven]] or HeraTherm oven. |

Numerous research groups perform direct wafer bonding (of various materials) using either the [[Wafer Bonder (SUSS SB6-8E)|Suss Wafer Bonder]], or a custom graphite fixture in conjunction with any one of [[Thermal Processing|numerous ovens]], such as the N2-purged [[Tube Furnace Wafer Bonding (Thermco)|Wafer Bonding Furnace]] (with glove box) or N2-purged [[High Temp Oven (Blue M)|Blue M oven]] or HeraTherm oven. |

||

| Line 44: | Line 64: | ||

The [[Plasma Activation (EVG 810)|EVG Plasma Activation]] system and [[Goniometer (Rame-Hart A-100)|Goniometer]] allow for surface prep/inspection prior to bonding. |

The [[Plasma Activation (EVG 810)|EVG Plasma Activation]] system and [[Goniometer (Rame-Hart A-100)|Goniometer]] allow for surface prep/inspection prior to bonding. |

||

| − | === |

+ | ===Bonding with Intermediate/adhesive layer=== |

| − | The [[Wafer Bonder (Logitech WBS7)|Logitech Bonder]] allows wafer-bonding with a CrystalBond wax intermediate layer. Please see [[ |

+ | The [[Wafer Bonder (Logitech WBS7)|Logitech Bonder]] allows wafer-bonding with a CrystalBond wax or other intermediate layer, while applying pressure to the top surface to improve uniform wax distribution. Please see the '''''Recipes > Packaging > [[Packaging Recipes#Wafer Bonder .28Logitech WBS7.29|<u>Logitech Bonder</u>]]''''' page for recipes. |

| − | == |

+ | ==[[Tube Furnace AlGaAs Oxidation (Lindberg)]]== |

Oxidation of AlGaAs (high-Aluminum content >90%) is performed in this furnace, at temperatures between 200°C → 500°C. |

Oxidation of AlGaAs (high-Aluminum content >90%) is performed in this furnace, at temperatures between 200°C → 500°C. |

||

| Line 54: | Line 74: | ||

Recipes are available, please ask the NanoFab Process group staff. |

Recipes are available, please ask the NanoFab Process group staff. |

||

| − | == |

+ | ==[[Rapid Thermal Processor (SSI Solaris 150)]]== |

[[Category:Processing]] |

[[Category:Processing]] |

||

{{todo|Add starting recipes for RTP}} |

{{todo|Add starting recipes for RTP}} |

||

Latest revision as of 16:24, 30 January 2024

Tystar 8300

Thermal Oxidation of Silicon - Calculating Oxidation Times

Online calculators for thermal oxidation can be used to estimate the oxidation time for a desired oxidation thickness. Please see the Calculators + Utilities page for links to these oxidation calculators.

Using the Stanford Leland Jr. "Advanced Silicon Thermal Oxide Thickness Calculator", we have determined the following simulation parameters (“partial pressure” in particular) to predict oxidation times. Please note, however, that doping level, impurity concentration and other factors can alter these calibrations, so you may need to calibrate the Partial Pressure yourself if you need higher accuracy.

A simpler but less accurate oxidation calculator can be found at the BYU Thermal Oxidation Calculator.

Wafer Cleaning

For Tube #2, Silicon wafer cleaning, the following process is recommended:

- If brand new wafers, they should be already relatively clean. Otherwise Acetone/ISO clean might be needed to remove particles - optional

- Use Bay 4 toxic corrosive bench to submerge wafers for 20min in PureStrip @ 60°C. Replenish if needed, since PureStrip degrades after a few days at 60°C.

- QDR - rinse.

- Transport to Bay 5 HF bench (keep in water - optional) - use Chemical Transport Container.

- Submerge in HF for 10min.

- Rinse in DI 3x at HF bench. Pure HF goes down special drain, while rinse water can go down normal drain.

- Dry with Nitrogen gun OR SRD "Spin Rinse Dryer" at Bay 5.

- Ready to load into Tystar quartz boats, run recipe on Tystar.

Thermal Oxidation Recipes

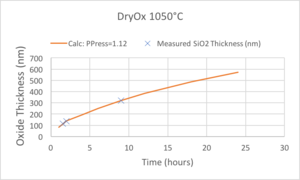

1050°C Dry Oxidation

- Recipe Name: DRY1050

- Tube #2 for Cleaned Silicon Only

- Tube #3 for processed silicon or other anneals.

Simulation Parameters

- Partial Pressure = 1.12 (best fit to measured data below)

- <100>, 1050°C, 10Å Native Oxide, no dopants

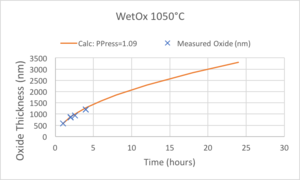

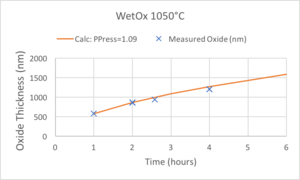

1050°C Wet Oxidation

- Recipe Name: WET1050

- Tube #2 for Cleaned Silicon Only

- Tube #3 for processed silicon or other anneals.

Simulation Parameters

- Partial Pressure = 1.09 (best fit to measured data below)

- <100>, 1050°C, 10Å Native Oxide, no dopants

AlGaAs Oxidation

A recipe is available on Tube #1 for thermal oxidation of AlGaAs layers, at much lower temperatures than Tubes #2 & #3. There are special procedures for running this lower-temp. oxidation at shorter times, please contact Tony Bosch or the NanoFab process Group for more information.

Wafer Substrate Bonding

Direct Bonding

Numerous research groups perform direct wafer bonding (of various materials) using either the Suss Wafer Bonder, or a custom graphite fixture in conjunction with any one of numerous ovens, such as the N2-purged Wafer Bonding Furnace (with glove box) or N2-purged Blue M oven or HeraTherm oven.

Il addition, the Fine-Tech Flip-Chip Bonder can perform aligned bonding of various-sized pieces. The Fine-Tech can do metal-to-metal thermo-compression bonding with ultrasonic assist.

The EVG Plasma Activation system and Goniometer allow for surface prep/inspection prior to bonding.

Bonding with Intermediate/adhesive layer

The Logitech Bonder allows wafer-bonding with a CrystalBond wax or other intermediate layer, while applying pressure to the top surface to improve uniform wax distribution. Please see the Recipes > Packaging > Logitech Bonder page for recipes.

Tube Furnace AlGaAs Oxidation (Lindberg)

Oxidation of AlGaAs (high-Aluminum content >90%) is performed in this furnace, at temperatures between 200°C → 500°C.

Maximum time is about 3 hours before the bubbler water temperature becomes uncontrolled.

Recipes are available, please ask the NanoFab Process group staff.

Rapid Thermal Processor (SSI Solaris 150)

| To Do: Add starting recipes for RTP |