Difference between revisions of "Stepper 2 (AutoStep 200)"

m (minor formatting) |

|||

| (40 intermediate revisions by 5 users not shown) | |||

| Line 2: | Line 2: | ||

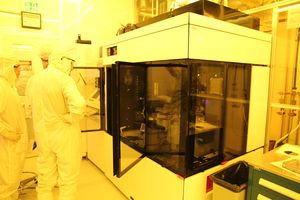

|picture=Stepper2.jpg |

|picture=Stepper2.jpg |

||

|type = Lithography |

|type = Lithography |

||

| − | |super= |

+ | |super= Biljana Stamenic |

|phone=(805)839-3918x213 |

|phone=(805)839-3918x213 |

||

|location=Bay 6 |

|location=Bay 6 |

||

| − | |email= |

+ | |email=stamenic@ucsb.edu |

|description = GCA 200 I-Line Wafer Stepper |

|description = GCA 200 I-Line Wafer Stepper |

||

|manufacturer = GCA |

|manufacturer = GCA |

||

| Line 12: | Line 12: | ||

}} |

}} |

||

| − | = |

+ | ==About== |

| − | Our GCA wafer stepper is an i-line (365 nm) step and repeat exposure tool for doing lithography that requires high resolution and/or critical alignment. The system has been modified to accept piece parts (down to |

+ | Our GCA wafer stepper is an i-line (365 nm) step and repeat exposure tool for doing lithography that requires high resolution and/or critical alignment. The system has been modified to accept piece parts (down to smaller than 10mm x 10mm) up to 6” diameter wafers using manual wafer loading. The maximum square die size is 14.8 mm x 14.8 mm. The system has an Olympus 2145 (N.A. = 0.45) lens that reduces the mask image by 5 x and gives an ultimate resolution of better than 0.5 um in the center of the lens field. The system can easily produce 0.7 um isolated lines across the entire field. The Autostep200 system has 3-point wafer leveling to improve focus uniformity across the field. Autofocus is used to determine the sample surface relative to the lens, making the focus stable and repeatable for different thickness of wafer. The stages are controlled by stepper motors and laser interferometers. Using the global, manual alignment, better than 0.25 um alignment error is achievable. Using the DFAS local alignment system, alignment error better than 0.15 um is achieved. With the 1000 W Hg arc lamp, we get about 420 mW/cm² of i-line intensity at the wafer. |

| − | The system is computer controlled with the capability to program and save a wide variety of exposure jobs. We also have unlimited phone support for system problems through a service contract. |

+ | The system is computer controlled with the capability to program and save a wide variety of exposure jobs. We also have unlimited phone support for system problems through a service contract. |

| + | |||

| − | =Detailed Specifications= |

+ | ==Detailed Specifications== |

| ⚫ | |||

| + | |||

| ⚫ | |||

*Maximum die size: ~ 15 mm x 15 mm |

*Maximum die size: ~ 15 mm x 15 mm |

||

| − | *Resolution: |

+ | *Resolution: 400-450 nm for R&D; 700 nm over entire 15 mm x 15 mm field |

| − | *Registration tolerance: 0. |

+ | *Registration tolerance: 0.25 µm global alignment; Max 0.15 µm local alignment (with care, you can achieve < 0.10 µm registration) |

| + | *Substrate size: ~ 10 x 10 mm up to 100 mm (150 mm possible, we don't provide the vacuum chuck for it). |

||

| − | *Minimum substrate size: ~ 10 x 10 mm |

||

*Computer programmable, recipes saved on hard disk |

*Computer programmable, recipes saved on hard disk |

||

| − | *Reticle alignment fiducials and global/local fiducials available |

+ | *Reticle alignment fiducials and global/local fiducials available - contact us for CAD files. |

| + | |||

| + | ==Process Information== |

||

| + | |||

| + | === Recipes === |

||

| + | *[https://signupmonkey.ece.ucsb.edu/wiki/index.php/Lithography_Recipes#Photolithography_Recipes Recipes > '''Photolithography Recipes'''] |

||

| + | |||

| + | ===Photoresists:=== |

||

| + | |||

| + | *The laboratory contains a variety of i-line compatible photoresists. See the [https://signupmonkey.ece.ucsb.edu/wiki/index.php/Lithography_Recipes#Photolithography_Recipes Photolith. Recipes Page] for detailed processing info (bakes/spins/exposure does etc.). Basic photoresists include: |

||

| + | **955CM-0.9 for 0.7-1.0 um thick positive processes. |

||

| + | **AZ5214E for 1.0 um thick image reversal (negative) process. |

||

| + | **SPR955CM-1.8 for 1.5-2.0 um thick positive processes. |

||

| + | **SPR220-3 for 2.5-5 um thick positive process. |

||

| + | **SPR220-7 for >5 um thick positive processes. |

||

| + | **AZnLOF5510 for <1.0um and AZnLOF 2020 for 1.5-3 um negative resist process. |

||

| + | **Shipley LOL-2000 is also used as an underlayer for high resolution lift-off processes. |

||

| + | |||

| + | ==Service Provider== |

||

| + | |||

| ⚫ | |||

| + | |||

| + | ==Operating Procedures== |

||

| + | *[[Stepper 2 (AutoStep 200) Operating Procedures|Standard Operating Procedure]] |

||

| − | =See Also= |

||

| + | *[[Stepper 2 (Autostep 200) - Job Programming|Programming a Job]] |

||

| ⚫ | |||

| + | *[[Autostep 200 Mask Making Guidance]] ('''''Work In Progress-not ready yet''''') |

||

| + | *[[Autostep 200 User Accessible Commands]] |

||

| + | *[[Autostep 200 Troubleshooting and Recovery|Troubleshooting and Recovery]] |

||

| + | *[[Autostep 200 Old training manual]] |

||

| + | == Staff Procedures == |

||

| − | =Documentation= |

||

| + | ''These procedures are for Staff use - contact staff if you think you need to run these!'' |

||

| − | * [[media:GCA-200-Training-Manual.pdf|Training Manual]] |

||

| + | * [[GCA Autostep200 - Startup-Shutdown Procedure|Shutdown + Startup Procedure]] |

||

Revision as of 07:14, 26 October 2020

|

About

Our GCA wafer stepper is an i-line (365 nm) step and repeat exposure tool for doing lithography that requires high resolution and/or critical alignment. The system has been modified to accept piece parts (down to smaller than 10mm x 10mm) up to 6” diameter wafers using manual wafer loading. The maximum square die size is 14.8 mm x 14.8 mm. The system has an Olympus 2145 (N.A. = 0.45) lens that reduces the mask image by 5 x and gives an ultimate resolution of better than 0.5 um in the center of the lens field. The system can easily produce 0.7 um isolated lines across the entire field. The Autostep200 system has 3-point wafer leveling to improve focus uniformity across the field. Autofocus is used to determine the sample surface relative to the lens, making the focus stable and repeatable for different thickness of wafer. The stages are controlled by stepper motors and laser interferometers. Using the global, manual alignment, better than 0.25 um alignment error is achievable. Using the DFAS local alignment system, alignment error better than 0.15 um is achieved. With the 1000 W Hg arc lamp, we get about 420 mW/cm² of i-line intensity at the wafer.

The system is computer controlled with the capability to program and save a wide variety of exposure jobs. We also have unlimited phone support for system problems through a service contract.

Detailed Specifications

- Lens: Olympus 2145: NA = 0.45; Depth of field = 1.2 um for 0.6 um process

- Maximum die size: ~ 15 mm x 15 mm

- Resolution: 400-450 nm for R&D; 700 nm over entire 15 mm x 15 mm field

- Registration tolerance: 0.25 µm global alignment; Max 0.15 µm local alignment (with care, you can achieve < 0.10 µm registration)

- Substrate size: ~ 10 x 10 mm up to 100 mm (150 mm possible, we don't provide the vacuum chuck for it).

- Computer programmable, recipes saved on hard disk

- Reticle alignment fiducials and global/local fiducials available - contact us for CAD files.

Process Information

Recipes

Photoresists:

- The laboratory contains a variety of i-line compatible photoresists. See the Photolith. Recipes Page for detailed processing info (bakes/spins/exposure does etc.). Basic photoresists include:

- 955CM-0.9 for 0.7-1.0 um thick positive processes.

- AZ5214E for 1.0 um thick image reversal (negative) process.

- SPR955CM-1.8 for 1.5-2.0 um thick positive processes.

- SPR220-3 for 2.5-5 um thick positive process.

- SPR220-7 for >5 um thick positive processes.

- AZnLOF5510 for <1.0um and AZnLOF 2020 for 1.5-3 um negative resist process.

- Shipley LOL-2000 is also used as an underlayer for high resolution lift-off processes.

Service Provider

- 3C Technical - The company that services the stepper.

Operating Procedures

- Standard Operating Procedure

- Programming a Job

- Autostep 200 Mask Making Guidance (Work In Progress-not ready yet)

- Autostep 200 User Accessible Commands

- Troubleshooting and Recovery

- Autostep 200 Old training manual

Staff Procedures

These procedures are for Staff use - contact staff if you think you need to run these!