Difference between revisions of "Sputtering Recipes"

(→Sputter 4 (AJA ATC 2200-V): added Ru ; link to SiO2 Etching with Ruthenium Hardmask doc.) |

|||

| (48 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

{{recipes|Vacuum Deposition}} |

{{recipes|Vacuum Deposition}} |

||

{{rl|Atomic Layer Deposition Recipes|Pt deposition (ALD)}} |

{{rl|Atomic Layer Deposition Recipes|Pt deposition (ALD)}} |

||

| − | |||

| − | =[[Sputter 2 (SFI Endeavor)]]= |

||

| − | == Al Deposition (Sputter 2) == |

||

| − | *[[media:20-Al-Sputtering-Film-Sputter-2.pdf|Al Deposition Recipe]] |

||

| − | == AlN<sub>x</sub> Deposition (Sputter 2) == |

||

| − | *[[media:Sputter-2-AlN-Endeavor-rev1.pdf|AlN<sub>x</sub> Deposition Recipe]] |

||

| − | |||

| − | == Au Deposition (Sputter 2) == |

||

| − | *[[media:21-Au-Sputter-film-recipes-Sputter-2.pdf|Au Deposition Recipe]] |

||

| − | == TiO<sub>2</sub> Deposition (Sputter 2) == |

||

| − | *[[media:22-TiO2-Film-Sputter-2.pdf|TiO2<sub>2</sub> Deposition Recipe]] |

||

=[[Sputter 3 (AJA ATC 2000-F)]]= |

=[[Sputter 3 (AJA ATC 2000-F)]]= |

||

| − | The recipes below are given as starting points from data obtained in the nanofab. For critical depositions, calibrations are recommended. |

+ | The recipes below are given as starting points from data obtained in the nanofab. For critical depositions, calibrations are recommended. Please see the [https://signupmonkey.ece.ucsb.edu/cgi-bin/users/browse.cgi?tool_ID=20 SignupMonkey Page] for a list of currently installed targets. |

{| class="wikitable sortable" |

{| class="wikitable sortable" |

||

|- |

|- |

||

| − | ! |

+ | !Material!!P(mT)!!Pow(W)!!Sub(W)!!T(C)!!Ar!!N2!!O2!!Height-Tilt!!Rate(nm/min)!!Stress(MPa)!!Rs(uOhm-cm)!!n@633nm!!k@633nm |

| + | !Target Consumed Lower Limit!!Data Below!!Comment |

||

|- |

|- |

||

| + | |Au |

||

| − | | Si || 8 || 250 || 0 || 25 || 25 || 0 || 0 || 15-3 || 1.4 || - || - || - || - || no || Gerhard - ramp 2W/s - 3% Unif 4" wafer |

||

| + | | - |

||

| + | | - |

||

| + | | - |

||

| + | | - |

||

| + | | - |

||

| + | | - |

||

| + | | - |

||

| + | | - |

||

| + | | - |

||

| + | | - |

||

| + | | - |

||

| + | | - |

||

| + | | - |

||

| + | |Set: 200 W |

||

| + | Read: 400 VDC |

||

| + | |no |

||

| + | | |

||

|- |

|- |

||

| + | |Al2O3 |

||

| − | | SiO2 || 3 || 200 || 10 || 20 || 25 || 0 || 3 || 25-9 || 3.68 || - || - || 1.447 || - || yes || Brian |

||

| + | |3 |

||

| + | |200 (RF2) |

||

| + | |off |

||

| + | |20 |

||

| + | |30 |

||

| + | | |

||

| + | |1.5 |

||

| + | |1.52"-4mm |

||

| + | |5.32 |

||

| + | | |

||

| + | | |

||

| + | |1.6478 |

||

| + | |0 |

||

| + | | |

||

| + | |no |

||

| + | |Demis D. John |

||

|- |

|- |

||

| − | | |

+ | |Co||10(5)||200||0||20||25||0||0||25-9||2.3||-||-||-||- |

| + | | ||yes||Alex K |

||

|- |

|- |

||

| − | | |

+ | |Cr||5||200||0||20||25||0||0||44-4||6.84||-||-||-||- |

| + | | ||no||Brian |

||

|- |

|- |

||

| − | | |

+ | |Cu||1.5||50(395v)||0||20||25||0||0||25-9||4.15||-||-||-||- |

| + | | ||no||Ning |

||

|- |

|- |

||

| − | | |

+ | |Cu||5||150(~490v)||0||20||15||0||0||0.82"-9||8||-||-||-||- |

| + | | ||yes||Ning |

||

|- |

|- |

||

| − | | |

+ | |Fe||10(5)||200||0||20||25||0||0||25-9||1.25||-||-||-||- |

| + | | ||No||Alex K |

||

|- |

|- |

||

| − | | |

+ | |Mo||3||200||0||20||25||0||0||44-4||13.15||-||-||-||- |

| + | | ||yes||Ning |

||

|- |

|- |

||

| − | | |

+ | |Ni||5||150||0||20||25||0||0||44-4||5.23||-||-||-||- |

| + | | ||yes||Ning |

||

|- |

|- |

||

| − | | |

+ | |Ni||5||150||0||20||25||0||0||25-9||1.82||-||-||-||- |

| + | | ||yes||Ning |

||

|- |

|- |

||

| − | | |

+ | |Ni||5||75||0||20||25||0||0||44-4||2.50||-||-||-||- |

| + | | ||yes||Ning |

||

|- |

|- |

||

| − | | |

+ | |Ni||3||200||0||20||25||0||0||44-4||9.4||-||-||-||- |

| + | | ||yes||Ning |

||

|- |

|- |

||

| − | | |

+ | |Ni||1.5||50(399v)||0||20||25||0||0||25-9||0.96||-||-||-||- |

| + | | ||no||Ning |

||

|- |

|- |

||

| − | | |

+ | |Pt||3||50||0||20||25||0||0||0.82"-9||2.9||-||-||-||- |

| + | | ||no||Ning |

||

|- |

|- |

||

| − | | |

+ | |Si||8||250||0||25||25||0||0||15-3||1.4||-||-||-||- |

| + | | ||no||Gerhard - ramp 2W/s - 3% Unif 4" wafer |

||

|- |

|- |

||

| − | | |

+ | |SiN||3||200||10||20||25||3||0||25-9||1.56||-||-||1.992||- |

| + | | ||yes||Brian |

||

|- |

|- |

||

| − | | |

+ | |SiN||3||250||10||20||25||2.5||0||25-9||2.1||-||-||2.06||- |

| + | | ||yes||Brian |

||

|- |

|- |

||

| − | | |

+ | |SiO2||3||200||10||20||25||0||3||25-9||3.68||-||-||1.447||- |

| + | | ||yes||Brian |

||

|- |

|- |

||

| − | | |

+ | |SiO2||3||200||10||20||25||0||5||45-3||2.60||-||-||1.471||- |

| + | | ||yes||Brian |

||

|- |

|- |

||

| − | | |

+ | |SiO2||3||250||10||20||25||0||2.5||25-9||4.3||-||-||1.485||- |

| + | | ||yes||Brian |

||

|- |

|- |

||

| − | | |

+ | |Ta||5||150||0||20||25||0||0||44-4||9.47||-||-||-||- |

| + | | ||yes||Ning |

||

| + | |- |

||

| + | |Ta||5||75||0||20||25||0||0||44-4||5.03||-||-||-||- |

||

| + | | ||yes||Ning |

||

| + | |- |

||

| + | |Ti||3||100||0||20||25||0||0||25-9||1.34||-||-||-||- |

||

| + | | ||yes||Ning |

||

| + | |- |

||

| + | |SampleClean-NativeSiO2||10||0||18||20||25||0||0||44-4||-||-||-||-||- |

||

| + | | ||yes||150Volts 5 min |

||

|- |

|- |

||

|} |

|} |

||

| + | ==Height Conversion for Older Recipes== |

||

| − | == Fe and Co Deposition (Sputter 3) == |

||

| + | Old recipes using the manual Height setting in millimeters can be converted to the new programmatic settings in inches as follows: |

||

| − | *[[media:Fe and Co Films using Sputter-3.pdf|Fe and Co Deposition Recipe]] |

||

| + | {| class="wikitable" |

||

| + | !Old (mm) |

||

| + | !New (inches) |

||

| + | !Typical Gun Tilt (mm) |

||

| + | |- |

||

| + | |15 |

||

| + | | |

||

| + | | |

||

| + | |- |

||

| + | |25 |

||

| + | |0.82 |

||

| + | |9 |

||

| + | |- |

||

| + | |44 |

||

| + | |1.52 |

||

| + | |4 |

||

| + | |} |

||

| + | Interpolation plot [[:File:Sputter 3 - height conversion v1.PNG|can be found here.]] |

||

| − | == |

+ | ==Fe and Co Deposition (Sputter 3)== |

| − | *[[media:46-Mo Film using Sputter3.pdf|Mo Deposition Recipe]] |

||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/1/15/Fe_and_Co_Films_using_Sputter-3.pdf Fe and Co Deposition Recipe] |

||

| − | == Ni and Ta Deposition (Sputter 3) == |

||

| − | *[[media:24-Ni and Ta Films using Sputter-3.pdf|Ni and Ta Deposition Recipe]] |

||

| − | *[[media:Ni Sputtering Film using Sputter 3-a.pdf|Ni Sputtering Film Recipe-3mT-200W]] |

||

| − | == |

+ | ==Cu Deposition (Sputter 3)== |

| − | *[[media:SiO2-AJA-1-Reactive-Sputter-Uniformity-rev-1.pdf|SiO2 Uniformity Data]] |

||

| − | *[[media:SiO2-AJA-1-Reactive-Sputter-Power-Flow-AFM-Roughness-rev1.pdf|SiO2 Flow and Bias Variations Including AFM Data]] |

||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/5/5e/Cu_Film_using_Sputter-3.pdf Cu Deposition Recipe] |

||

| − | == SiN Deposition (Sputter 3) == |

||

| − | *[[media:SiN-AJA-1-Reactive-Sputtering-Power-Flow-AFM-Rate-Index-rev1.pdf|SiN Flow and RF Variations Including AFM Data]] |

||

| − | == |

+ | ==Mo Deposition (Sputter 3)== |

| + | |||

| − | *[[media:Ti Sputtering Film using Sputter 3.pdf|Ti Sputtering Film Recipe-3mT-100W]] |

||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/7/7f/46-Mo_Film_using_Sputter3.pdf Mo Deposition Recipe] |

||

| + | |||

| + | ==Ni and Ta Deposition (Sputter 3)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/b/b6/24-Ni_and_Ta_Films_using_Sputter-3.pdf Ni and Ta Deposition Recipe] |

||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/9/93/Ni_Sputtering_Film_using_Sputter_3-a.pdf Ni Sputtering Film Recipe-3mT-200W] |

||

| + | |||

| + | ==SiO2 Deposition (Sputter 3)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/e/ef/SiO2-AJA-1-Reactive-Sputter-Uniformity-rev-1.pdf SiO2 Uniformity Data] |

||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/b/b2/SiO2-AJA-1-Reactive-Sputter-Power-Flow-AFM-Roughness-rev1.pdf SiO2 Flow and Bias Variations Including AFM Data] |

||

| + | |||

| + | ==SiN Deposition (Sputter 3)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/f/fb/SiN-AJA-1-Reactive-Sputtering-Power-Flow-AFM-Rate-Index-rev1.pdf SiN Flow and RF Variations Including AFM Data] |

||

| + | |||

| + | ==Ti Deposition (Sputter 3)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/3/3b/Ti_Sputtering_Film_using_Sputter_3.pdf Ti Sputtering Film Recipe-3mT-100W] |

||

=[[Sputter 4 (AJA ATC 2200-V)]]= |

=[[Sputter 4 (AJA ATC 2200-V)]]= |

||

| − | The recipes below are given as starting points from data obtained in the nanofab. For critical depositions, calibrations are recommended. |

+ | The recipes below are given as starting points from data obtained in the nanofab. For critical depositions, calibrations are recommended. Please see [https://signupmonkey.ece.ucsb.edu/cgi-bin/users/browse.cgi?tool_ID=21 the SignupMonkey page] for a list of currently installed targets. |

{| class="wikitable sortable" |

{| class="wikitable sortable" |

||

|- |

|- |

||

| + | !Material!!P(mT) |

||

| − | ! Material !! P(mT) !! Pow(W) !! Sub(W) !! T(C) !! Ar !! N2 !! O2 !! Height-Tilt !! Rate(nm/min) !! Stress(MPa) !! Rs(uOhm-cm) !! n@633nm !! k@633nm !! Data Below !! Comment |

||

| + | !Power Source!!Pow(W)!!Sub(W)!!T(C)!!Ar!!N2!!O2!!Height-Tilt!!Rate(nm/min)!!Stress(MPa)!!Rs(uOhm-cm)!!n@633nm!!k@633nm!!Data Below!!Comment |

||

|- |

|- |

||

| + | |Al||5 |

||

| − | | W || 3 || 300 || 0 || 50 || 45 || 0 || 0 || H2.75-T5 || 11.5 || -150 to 150 || 11 || - || - || Yes || Jeremy Watcher |

||

| + | | ||200||0||20||45||0||0||H2.75-T5||4.4||-||-||-||-||Yes||Ning Cao |

||

|- |

|- |

||

| + | |Al2O3 |

||

| − | | TiW || 4.5 || 200 || 0 || 20 || 45 || 0 || 0 || H1-T10 || 4.7 || - || - || - || - || Yes || Ning Cao |

||

| + | |3 |

||

| + | |RF4-Sw1 |

||

| + | |200 |

||

| + | |0 |

||

| + | |20 |

||

| + | |30 |

||

| + | |0 |

||

| + | |1.5 |

||

| + | |H2.75-T5 |

||

| + | |5.1 |

||

| + | | |

||

| + | | |

||

| + | |1.64202 |

||

| + | |0 |

||

| + | |partial |

||

| + | |Demis D. John |

||

|- |

|- |

||

| + | |Au||5 |

||

| − | | TiW || 4.5 || 300 || 0 || 75 || 45 || 0 || 0 || H2.75-T5 || 9.5 || -150 to 150 || 60 || - || - || Yes || 10%Ti by Wt |

||

| + | | ||200||0||20||45||0||0||H1-T10||17.7||-||-||-||-||Yes||Ning Cao |

||

|- |

|- |

||

| + | |Au||10 |

||

| − | | TiN || 3 || 150 || 110V || 20 || 48.25 || 1.75 || 0 || H2.5-T5 || 2 || - || 60 || - || - || No || |

||

| + | | ||300||0||20||45||0||0||H2.75-T5||45.4||-||-||-||-||Yes||Ning Cao |

||

|- |

|- |

||

| + | |Cu |

||

| − | | TiO<sub>2</sub> || 3 || 250(RF:450V) || 0 || 20 || 45 || 0 || 3 || H2.75-T5 ||4.3|| - || || - || - || Yes || Ning Cao |

||

| + | |5 |

||

| + | | |

||

| + | |150 |

||

| + | |0 |

||

| + | |20 |

||

| + | |30 |

||

| + | |0 |

||

| + | |0 |

||

| + | |H0.82-T9 |

||

| + | |6.7 |

||

| + | | |

||

| + | | |

||

| + | | |

||

| + | | |

||

| + | |No (SEM available) |

||

| + | |Ning Cao |

||

|- |

|- |

||

| + | |Nb||4 |

||

| − | | Nb || 4 || 250 || 0 || 20 || 30 || 0 || 0 || H2.00-T7 || 7.5 || - || - || - || - || No || |

||

| + | | ||250||0||20||30||0||0||H2.00-T7||7.5||-||-||-||-||No|| |

||

|- |

|- |

||

| + | |Pt||5 |

||

| − | | Ti || 10 || 200 || 0 || 20 || 45 || 0 || 0 || H2.75-T5 || 2.3 || - || - || - || - || Yes || Ning Cao |

||

| + | | ||200||0||20||45||0||0||H2.75-T5||7.4||-||-||-||-||Yes||Ning Cao |

||

|- |

|- |

||

| + | |Pt||3 |

||

| − | | Au || 5 || 200 || 0 || 20 || 45 || 0 || 0 || H1-T10 || 17.7 || - || - || - || - || Yes || Ning Cao |

||

| + | | ||50(439V)||0||20||45||0||0||H2.75-T5||3.9||-||-||-||-||Yes||Ning Cao |

||

|- |

|- |

||

| + | |Ru |

||

| − | | Au || 10 || 300 || 0 || 20 || 45 || 0 || 0 || H2.75-T5 || 45.4 || - || - || - || - || Yes || Ning Cao |

||

| + | |3 |

||

| + | | |

||

| + | |200 |

||

| + | | |

||

| + | | |

||

| + | |45 |

||

| + | | |

||

| + | | |

||

| + | |H2.75-T4 |

||

| + | |~10 |

||

| + | | |

||

| + | | |

||

| + | | |

||

| + | | |

||

| + | |Yes |

||

| + | |Ning Cao |

||

|- |

|- |

||

| + | |Ti||10 |

||

| − | | Al || 5 || 200 || 0 || 20 || 45 || 0 || 0 || H2.75-T5 || 4.4 || - || - || - || - || Yes || Ning Cao |

||

| + | | ||200||0||20||45||0||0||H2.75-T5||2.3||-||-||-||-||Yes||Ning Cao |

||

|- |

|- |

||

| + | |TiN||3 |

||

| − | | Pt || 5 || 200 || 0 || 20 || 45 || 0 || 0 || H2.75-T5 || 7.4 || - || - || - || - || Yes || Ning Cao |

||

| + | | ||150||110V||20||48.25||1.75||0||H2.5-T5||2||-||60||-||-||No|| |

||

|- |

|- |

||

| + | |TiO<sub>2</sub>||3 |

||

| − | | Pt || 3 || 50(439V) || 0 || 20 || 45 || 0 || 0 || H2.75-T5 || 3.9 || - || - || - || - || Yes || Ning Cao |

||

| + | | ||250(RF:450V)||0||20||45||0||3||H2.75-T5||4.3||-|| ||-||-||Yes||Ning Cao |

||

| + | |- |

||

| + | |TiW||4.5 |

||

| + | | ||200||0||20||45||0||0||H1-T10||4.7||-||-||-||-||Yes||Ning Cao |

||

| + | |- |

||

| + | |TiW||4.5 |

||

| + | | ||300||0||75||45||0||0||H2.75-T5||9.5||-150 to 150||60||-||-||Yes||10%Ti by Wt |

||

| + | |- |

||

| + | |W||3 |

||

| + | | ||300||0||50||45||0||0||H2.75-T5||11.5||-150 to 150||11||-||-||Yes||Jeremy Watcher |

||

|- |

|- |

||

|} |

|} |

||

| − | == W-TiW Deposition (Sputter 4) == |

||

| − | *[[media:W-TiW-Sputtering-AJA-4-Data-Recipe-RevB.pdf|W-TiW Deposition Recipe]] |

||

| − | == |

+ | ==Au Deposition (Sputter 4)== |

| − | *[[media:Ti-Au-Sputtering-Films-AJA2-rev1.pdf|Ti-Au Deposition Recipe and SEM Cross-Sections]] |

||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/0/01/Au-Sputter4-5mT-200W-120s.pdf Au Film's AFM Step and Roughness] |

||

| − | == Pt Deposition (Sputter 4) == |

||

| − | *[[media:Pt-Sputter4.pdf|Pt Film's AFM Step and Roughness]] |

||

| − | == |

+ | ==Al Deposition (Sputter 4)== |

| − | *[[media:TiW-Sputter4-4.5mT-300W-300s.pdf|TiW Film's AFM Step and Roughness]] |

||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/1/17/Al-Sputter4-5mT-200W-30m.pdf Al Film SEM Profile] |

||

| − | == TiO<sub>2</sub> Deposition (Sputter 4) == |

||

| − | *[[media:TiO2 film using Sputter4.pdf|TiO<sub>2</sub> Film's Refractive Index Spectrum, Resistivity, AFM Roughness]] |

||

| − | == |

+ | ==Al2O3 Deposition (Sputter 4)== |

| − | *[[media:Au-Sputter4-5mT-200W-120s.pdf|Au Film's AFM Step and Roughness]] |

||

| + | *Rate: 5.134 nm/min |

||

| − | == Al Deposition (Sputter 4) == |

||

| + | *[https://en.wikipedia.org/wiki/Cauchy%27s_equation Cauchy] Refractive Index Params (fit from λ=190-1700nm, indicating transparency over this range) |

||

| − | *[[media:Al-Sputter4-5mT-200W-30m.pdf|Al Film SEM Profile]] |

||

| + | **A = 1.626 |

||

| + | **B = 5.980E-3 |

||

| + | **C = 1.622E-4 |

||

| + | ==Pt Deposition (Sputter 4)== |

||

| − | =[[Sputter 5 (Lesker AXXIS)]]= |

||

| + | |||

| − | '''NOTE: This tool has been replaced by a third AJA Sputter tool, nearly identical to Sputter #4 except that magnetic materials are allowed. Website updates pending.''' |

||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/a/ab/Pt-Sputter4.pdf Pt Film's AFM Step and Roughness] |

||

| − | '''-- 2017-11-02''' |

||

| + | |||

| + | == Ru Deposition (Sputter 4) == |

||

| + | * [https://wiki.nanotech.ucsb.edu/w/images/f/f6/SiO2_Etch%2C_Ru_HardMask_-_Fluorine_ICP_Etch_Process_-_Ning_Cao_2019-06.pdf Ruthenium Hardmask for SiO2 Etching - Full Process Traveler] by Ning Cao |

||

| + | ** Deposition Rate ~10nm/min |

||

| + | ** See [[ICP Etching Recipes#SiO2 Etching|Fluorine-ICP > SiO2 Etching]] page for more info. |

||

| + | |||

| + | ==Ti-Au Deposition (Sputter 4)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/8/89/Ti-Au-Sputtering-Films-AJA2-rev1.pdf Ti-Au Deposition Recipe and SEM Cross-Sections] |

||

| + | |||

| + | ==TiO<sub>2</sub> Deposition (Sputter 4)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/1/19/TiO2_film_using_Sputter4.pdf TiO<sub>2</sub> Film's Refractive Index Spectrum, Resistivity, AFM Roughness] |

||

| + | |||

| + | ==TiW Deposition (Sputter 4)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/7/78/TiW-Sputter4-4.5mT-300W-300s.pdf TiW Film's AFM Step and Roughness] |

||

| + | ==W-TiW Deposition (Sputter 4)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/c/cc/W-TiW-Sputtering-AJA-4-Data-Recipe-RevB.pdf W-TiW Deposition Recipe] |

||

| + | |||

| + | =[[Sputter 5 (AJA ATC 2200-V)]]= |

||

The recipes below are given as starting points from data obtained in the nanofab. For critical depositions, calibrations are recommended. |

The recipes below are given as starting points from data obtained in the nanofab. For critical depositions, calibrations are recommended. |

||

| + | |||

| + | Please see the [https://signupmonkey.ece.ucsb.edu/cgi-bin/users/browse.cgi?tool_ID=60 SignupMonkey] page for a list of currently installed targets. |

||

{| class="wikitable sortable" |

{| class="wikitable sortable" |

||

|- |

|- |

||

| + | !Material!!P(mT) |

||

| − | ! Material !! P(mT) !! Pow(W) !! Sub(V) !! T(C) !! Ar !! N2 !! O2 !! Height-Tilt !! Rate(nm/min) !! Stress(MPa) !! Rs(uOhm-cm) !! Rq(nm)!! n@633nm !! k@633nm !! LPDb/LPDa!! Data Below !! Comment |

||

| + | !Power Source!!Pow(W)!!Sub(V)!!T(C)!!Ar!!N2!!O2!!Height-Tilt!!Rate(nm/min)!!Stress(MPa)!!Rs(uOhm-cm)!!Rq(nm)!!n@633nm!!k@633nm!!LPDb/LPDa*!!Data Below!!Comment |

||

| + | |- |

||

| + | |Al |

||

| + | |5 |

||

| + | | |

||

| + | |250 |

||

| + | |0 |

||

| + | |20 |

||

| + | |45 |

||

| + | |0 |

||

| + | |0 |

||

| + | |H1-T10 |

||

| + | |2.5 |

||

| + | |22 |

||

| + | | |

||

| + | | |

||

| + | | |

||

| + | | |

||

| + | | |

||

| + | |No (SEM available) |

||

| + | |Ning |

||

| + | |- |

||

| + | |Al2O3 |

||

| + | |1.5 |

||

| + | |DC5-SW1 |

||

| + | |150 |

||

| + | | - |

||

| + | | - |

||

| + | |45 |

||

| + | | - |

||

| + | |5 |

||

| + | |H2.75-T5 |

||

| + | |5.3 |

||

| + | |? |

||

| + | |? |

||

| + | |? |

||

| + | |1.641 |

||

| + | | - |

||

| + | |? |

||

| + | |No |

||

| + | |Demis 2018-04-13 |

||

|- |

|- |

||

| + | |SiO2||3 |

||

| − | | SiO2 || 3 || 250 || 120 || 20 || 45 || 0 || 2 || H1.0-T10 || 2.32 || || - || - ||1.49 || - || 153/6384 || No || Biljana |

||

| + | | ||250||120||20||45||0||2||H1.0-T10||2.32|| ||-||-||1.49||-||153/6384||No||Biljana |

||

|- |

|- |

||

| + | |SiO2||3 |

||

| − | | SiO2 || 3 || 250 || 120 || 20 || 45 || 0 || 4.5 || H1.0-T10 || 2.29 || -515 || - || 0.210 || 1.49 || || 138/4445 || No ( AFM available) || Biljana |

||

| + | | ||250||120||20||45||0||4.5||H1.0-T10||2.29||-515||-||0.210||1.49|| ||138/4445||No ( AFM available)||Biljana |

||

|- |

|- |

||

| + | |SiO2||3 |

||

| − | | SiO2 || 3 || 250 || 120 || 20 || 45 || 0 || 6 || H1.0-T10 || 2.32|| || - || - || 1.49 || - || 27/1515 || Yes || Biljana |

||

| + | | ||250||120||20||45||0||6||H1.0-T10||2.32|| ||-||-||1.49||-||27/1515||Yes||Biljana |

||

|- |

|- |

||

|} |

|} |

||

| + | ''*LPD: light particle detection:'' |

||

| − | * |

+ | *''LPDb: light particle detection before deposition'' |

| − | * |

+ | *''LPDa: light particle detection after deposition'' |

| − | *LPDa- light particle detection after deposition |

||

| − | == SiO2 Deposition (Sputter 5) == |

||

| + | ==SiO2 Deposition (Sputter 5)== |

||

*[https://docs.google.com/spreadsheets/d/1kzrbXdUJNf_-FjLJd-PTrbGDhGCKNNxo_JaOXkSpAF8/edit#gid=Sputter#5 SiO2 film] |

*[https://docs.google.com/spreadsheets/d/1kzrbXdUJNf_-FjLJd-PTrbGDhGCKNNxo_JaOXkSpAF8/edit#gid=Sputter#5 SiO2 film] |

||

| Line 167: | Line 380: | ||

=[[Ion Beam Deposition (Veeco NEXUS)]]= |

=[[Ion Beam Deposition (Veeco NEXUS)]]= |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AuBs1GfMrpnXcEdXanZQNko3X0lUcHhVUlNyYnVDUkE&usp=sharing IBD Calibrations Spreadsheet] - Records of historical film depositions (rates, indices), Uniformity etc. |

+ | *[https://docs.google.com/spreadsheet/ccc?key=0AuBs1GfMrpnXcEdXanZQNko3X0lUcHhVUlNyYnVDUkE&usp=sharing IBD Calibrations Spreadsheet] - Records of historical film depositions (rates, indices), Uniformity etc. |

| + | **'''All users are required to enter their calibration deps (simple test deps only)''' |

||

*[https://docs.google.com/spreadsheets/d/1y704PRxvXf8bbqb79CrISnk2t0FeojYVJIjrAcBU2_w/edit#gid=sharing Particulates in SiO2 and Ta2O5 in 2015] |

*[https://docs.google.com/spreadsheets/d/1y704PRxvXf8bbqb79CrISnk2t0FeojYVJIjrAcBU2_w/edit#gid=sharing Particulates in SiO2 and Ta2O5 in 2015] |

||

| − | '''All users are required to enter their calibration deps (simple test deps only)''' |

||

==SiO{{sub|2}} deposition (IBD)== |

==SiO{{sub|2}} deposition (IBD)== |

||

| + | |||

| − | *[[media: New IBD SiO2 Standard Recipe.pdf |SiO<sub>2</sub> Standard Recipe]] |

||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/8/8d/New_IBD_SiO2_Standard_Recipe.pdf SiO<sub>2</sub> Standard Recipe] |

||

*[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dFRJLUZUdXB4WFA1S1BMMWQ4WndpTWc&usp=drive_web#gid=sharing SiO<sub>2</sub> Data December 2014] |

*[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dFRJLUZUdXB4WFA1S1BMMWQ4WndpTWc&usp=drive_web#gid=sharing SiO<sub>2</sub> Data December 2014] |

||

*[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dGNyV083bmpzMjZpZ0JFVWhoOUpaN3c#gid=sharing SiO<sub>2</sub> Thickness uniformity 2014] |

*[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dGNyV083bmpzMjZpZ0JFVWhoOUpaN3c#gid=sharing SiO<sub>2</sub> Thickness uniformity 2014] |

||

| Line 182: | Line 396: | ||

*[https://docs.google.com/spreadsheets/d/1dFI1B2WxS7oEGMPl2dlLtmiAin-6EKWSEj9hFezB4_w/edit#gid==sharing SiO<sub>2</sub> Thickness uniformity-1hr depositions 2016] |

*[https://docs.google.com/spreadsheets/d/1dFI1B2WxS7oEGMPl2dlLtmiAin-6EKWSEj9hFezB4_w/edit#gid==sharing SiO<sub>2</sub> Thickness uniformity-1hr depositions 2016] |

||

| + | ======SiO2 1hr deposition properties:====== |

||

| − | |||

| − | *SiO2 1hr depositions: |

||

*Dep.rate: ≈ 5.2 nm/min (users must calibrate this prior to critical deps) |

*Dep.rate: ≈ 5.2 nm/min (users must calibrate this prior to critical deps) |

||

*HF e.r.~350 nm/min |

*HF e.r.~350 nm/min |

||

| Line 190: | Line 403: | ||

*Refractive Index: ≈ 1.494 |

*Refractive Index: ≈ 1.494 |

||

*[[http://en.wikipedia.org/wiki/Cauchy's_equation Cauchy Parameters]] (350-2000nm): |

*[[http://en.wikipedia.org/wiki/Cauchy's_equation Cauchy Parameters]] (350-2000nm): |

||

| − | ** |

+ | **A = 1.480 |

| − | ** |

+ | **B = 0.00498 |

| − | ** |

+ | **C = -3.2606e-5 |

| + | |||

| + | ==Si<sub>3</sub>N<sub>4</sub> deposition (IBD)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/d/d3/IBD_SiNdeposition.pdf Si<sub>3</sub>N<sub>4</sub> Standard Recipe] |

||

| + | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dDE4RldRQnA1N1ptOUlHQVc3QjNXSkE#gid=sharing Si<sub>3</sub>N<sub>4</sub> Data December 2014] |

||

| + | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dEdsbWRhYW9mbFRLem56TjFFWjRwR1E#gid=sharing Si<sub>3</sub>N<sub>4</sub> Thickness uniformity 2014] |

||

| + | |||

| + | *Deposition Rate: ≈ 4.10 nm/min (users must calibrate this prior to critical deps) |

||

| + | *HF e.r.~11nm/min |

||

| + | *Stress ≈ -1590MPa (compressive) |

||

| + | *Refractive Index: ≈ 1.969 |

||

| + | *[[http://en.wikipedia.org/wiki/Cauchy's_equation Cauchy Parameters]] (350-2000nm): |

||

| + | **A = 2.000 |

||

| + | **B = 0.01974 |

||

| + | **C = 1.2478e-4 |

||

| + | |||

| + | ==SiO<sub>x</sub>N<sub>y</sub> deposition (IBD)== |

||

| + | These are some old (2010), initial characterizations only. A recipe improvement would be to increase the Assist O2+N2 = 60sccm total, increasing repeatability. Contact [[Demis D. John|Demis]] for more info. |

||

| + | {| |

||

| + | ![[File:IBD SiON Index @ 623nm vs. O2 Gas Flow - v3 - wiki.jpg|alt=plot showing varying refractive index between Si3N4 and SiO2|none|thumb|250x250px|IBD SiO<sub>x</sub>N<sub>y</sub>: Refractive Index vs. O2/N2 Flow.]] |

||

| + | ![[File:IBD SiON - Dep rate vs O2 flow - wiki.png|alt=Rate varies monotonically from 53-5 Å/min.|none|thumb|Dep. Rate of IBD SiO<sub>x</sub>N<sub>y</sub> vs. Assist O<sub>2</sub> flow.]] |

||

| + | |} |

||

==Ta{{sub|2}}O{{sub|5}} deposition (IBD)== |

==Ta{{sub|2}}O{{sub|5}} deposition (IBD)== |

||

| − | *[ |

+ | *[//wiki.nanotech.ucsb.edu/wiki/images/8/85/IBD_Ta2O5_deposition_details.pdf Ta{{sub|2}}O{{sub|5}} Standard Recipe] |

*[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dGhhUGdCR2JudkZJU3pBemR4bS1GWWc#gid=0=sharing Ta{{sub|2}}O{{sub|5}} Data December 2014] |

*[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dGhhUGdCR2JudkZJU3pBemR4bS1GWWc#gid=0=sharing Ta{{sub|2}}O{{sub|5}} Data December 2014] |

||

*[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dE5xbVFyUFZqdTdUN0JRSUNvMGFGb2c#gid=sharing Ta{{sub|2}}O{{sub|5}} Thickness uniformity 2014] |

*[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dE5xbVFyUFZqdTdUN0JRSUNvMGFGb2c#gid=sharing Ta{{sub|2}}O{{sub|5}} Thickness uniformity 2014] |

||

| Line 214: | Line 449: | ||

*Refractive Index: ≈ 2.172 |

*Refractive Index: ≈ 2.172 |

||

*[[http://en.wikipedia.org/wiki/Cauchy's_equation Cauchy Parameters]] (350-2000nm): |

*[[http://en.wikipedia.org/wiki/Cauchy's_equation Cauchy Parameters]] (350-2000nm): |

||

| − | ** |

+ | **A = 2.1123 |

| − | ** |

+ | **B = 0.018901 |

| − | ** |

+ | **C = -0.016222 |

| − | |||

| − | ==Si<sub>3</sub>N<sub>4</sub> deposition (IBD)== |

||

| − | *[[media:IBD SiNdeposition.pdf|Si<sub>3</sub>N<sub>4</sub> Standard Recipe]] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dDE4RldRQnA1N1ptOUlHQVc3QjNXSkE#gid=sharing Si<sub>3</sub>N<sub>4</sub> Data December 2014] |

||

| − | *[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dEdsbWRhYW9mbFRLem56TjFFWjRwR1E#gid=sharing Si<sub>3</sub>N<sub>4</sub> Thickness uniformity 2014] |

||

| − | |||

| − | *Deposition Rate: ≈ 4.10 nm/min (users must calibrate this prior to critical deps) |

||

| − | *HF e.r.~11nm/min |

||

| − | *Stress ≈ -1590MPa (compressive) |

||

| − | *Refractive Index: ≈ 1.969 |

||

| − | *[[http://en.wikipedia.org/wiki/Cauchy's_equation Cauchy Parameters]] (350-2000nm): |

||

| − | ** A = 2.000 |

||

| − | ** B = 0.01974 |

||

| − | ** C = 1.2478e-4 |

||

==TiO{{sub|2}} deposition (IBD)== |

==TiO{{sub|2}} deposition (IBD)== |

||

| + | |||

| − | *[[media:New IBD TiO2 deposition.pdf|TiO<sub>2</sub> Standard Recipe]] |

||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/3/3b/New_IBD_TiO2_deposition.pdf TiO<sub>2</sub> Standard Recipe] |

||

*[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dGVXVkM4dEdXaU15M09HNGhJbGUycVE#gid=sharing TiO<sub>2</sub> Data December 2014] |

*[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dGVXVkM4dEdXaU15M09HNGhJbGUycVE#gid=sharing TiO<sub>2</sub> Data December 2014] |

||

*[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dF9YSW9jTDJzY19MbmVEbUQtVzJVdVE#gid=sharing TiO<sub>2</sub> Thickness uniformity 2014] |

*[https://docs.google.com/spreadsheet/ccc?key=0AnwBU1s4JQo2dF9YSW9jTDJzY19MbmVEbUQtVzJVdVE#gid=sharing TiO<sub>2</sub> Thickness uniformity 2014] |

||

| Line 242: | Line 464: | ||

*Refractive Index: ≈ 2.259 |

*Refractive Index: ≈ 2.259 |

||

*[[http://en.wikipedia.org/wiki/Cauchy's_equation Cauchy Parameters]] (350-2000nm): |

*[[http://en.wikipedia.org/wiki/Cauchy's_equation Cauchy Parameters]] (350-2000nm): |

||

| − | ** |

+ | **A = 2.435 |

| − | ** |

+ | **B = -4.9045e-4 |

| − | ** |

+ | **C = 0.01309 |

*Absorbing < ~350nm |

*Absorbing < ~350nm |

||

| − | == |

+ | ==Al2O3 deposition (IBD)== |

| + | |||

| − | * Al2O3 standard recipe ( working on) |

||

| + | *Al2O3 standard recipe: 1_Al2O3_dep |

||

| − | * [https://docs.google.com/spreadsheets/d/14ko5HCZscOncxPpKi1ceREFa-Y1VKqnBN_o3j6izXTM/edit#gid= Al2O3 Data 2017] |

||

| + | |||

| − | * [https://docs.google.com/spreadsheets/d/1O5EniZONk8Mz0khUu8FNtRDAvRU8xz6y7Tt_kkPIjbE/edit#gid= Al2O3 Thickness uniformity 2017] |

||

| + | *[https://docs.google.com/spreadsheets/d/1Qwxa7rtq2kGeFUQxnjGFgtdCJP4uIX_bdUcCWFvO72g/edit#gid= Al2O3 Data 2018] |

||

| + | *[https://docs.google.com/spreadsheets/d/1rjwDQ0WJOIL7XWx2KWQ4fEPjNkr6GEmiXGmQXZnWFOI/edit#gid= Al2O3 Thickness uniformity 2018] |

||

*Deposition Rate: ≈ 2.05nm/min (users must calibrate this prior to critical deps) |

*Deposition Rate: ≈ 2.05nm/min (users must calibrate this prior to critical deps) |

||

*HF etch rate ~167nm/min |

*HF etch rate ~167nm/min |

||

| − | *Stress ≈ - |

+ | *Stress ≈ -332MPa (compressive) |

*Refractive Index: ≈ 1.656 |

*Refractive Index: ≈ 1.656 |

||

*[[http://en.wikipedia.org/wiki/Cauchy's_equation Cauchy Parameters]] (350-2000nm):( working on) |

*[[http://en.wikipedia.org/wiki/Cauchy's_equation Cauchy Parameters]] (350-2000nm):( working on) |

||

| − | ** |

+ | **A = |

| − | ** |

+ | **B = |

| − | ** |

+ | **C = |

*Absorbing < ~350nm |

*Absorbing < ~350nm |

||

| + | |||

| + | |||

| + | |||

| + | = [[Sputter 2 (SFI Endeavor)|<big><u>Sputter 2 (SFI Endeavor)</u></big>]] = |

||

| + | '''This Tool has been Disabled, and is not available for use any more! These recipes are displayed here for historical/reference purposes only.''' |

||

| + | |||

| + | ==Al Deposition (Sputter 2)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/0/05/20-Al-Sputtering-Film-Sputter-2.pdf Al Deposition Recipe] |

||

| + | |||

| + | ==AlN<sub>x</sub> Deposition (Sputter 2)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/8/8c/Sputter-2-AlN-Endeavor-rev1.pdf AlN<sub>x</sub> Deposition Recipe] |

||

| + | |||

| + | ==Au Deposition (Sputter 2)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/8/8a/21-Au-Sputter-film-recipes-Sputter-2.pdf Au Deposition Recipe] |

||

| + | |||

| + | ==TiO<sub>2</sub> Deposition (Sputter 2)== |

||

| + | |||

| + | *[//wiki.nanotech.ucsb.edu/wiki/images/c/c4/22-TiO2-Film-Sputter-2.pdf TiO2<sub>2</sub> Deposition Recipe] |

||

Revision as of 10:47, 12 January 2021

Back to Vacuum Deposition Recipes. R

Sputter 3 (AJA ATC 2000-F)

The recipes below are given as starting points from data obtained in the nanofab. For critical depositions, calibrations are recommended. Please see the SignupMonkey Page for a list of currently installed targets.

| Material | P(mT) | Pow(W) | Sub(W) | T(C) | Ar | N2 | O2 | Height-Tilt | Rate(nm/min) | Stress(MPa) | Rs(uOhm-cm) | n@633nm | k@633nm | Target Consumed Lower Limit | Data Below | Comment |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Au | - | - | - | - | - | - | - | - | - | - | - | - | - | Set: 200 W

Read: 400 VDC |

no | |

| Al2O3 | 3 | 200 (RF2) | off | 20 | 30 | 1.5 | 1.52"-4mm | 5.32 | 1.6478 | 0 | no | Demis D. John | ||||

| Co | 10(5) | 200 | 0 | 20 | 25 | 0 | 0 | 25-9 | 2.3 | - | - | - | - | yes | Alex K | |

| Cr | 5 | 200 | 0 | 20 | 25 | 0 | 0 | 44-4 | 6.84 | - | - | - | - | no | Brian | |

| Cu | 1.5 | 50(395v) | 0 | 20 | 25 | 0 | 0 | 25-9 | 4.15 | - | - | - | - | no | Ning | |

| Cu | 5 | 150(~490v) | 0 | 20 | 15 | 0 | 0 | 0.82"-9 | 8 | - | - | - | - | yes | Ning | |

| Fe | 10(5) | 200 | 0 | 20 | 25 | 0 | 0 | 25-9 | 1.25 | - | - | - | - | No | Alex K | |

| Mo | 3 | 200 | 0 | 20 | 25 | 0 | 0 | 44-4 | 13.15 | - | - | - | - | yes | Ning | |

| Ni | 5 | 150 | 0 | 20 | 25 | 0 | 0 | 44-4 | 5.23 | - | - | - | - | yes | Ning | |

| Ni | 5 | 150 | 0 | 20 | 25 | 0 | 0 | 25-9 | 1.82 | - | - | - | - | yes | Ning | |

| Ni | 5 | 75 | 0 | 20 | 25 | 0 | 0 | 44-4 | 2.50 | - | - | - | - | yes | Ning | |

| Ni | 3 | 200 | 0 | 20 | 25 | 0 | 0 | 44-4 | 9.4 | - | - | - | - | yes | Ning | |

| Ni | 1.5 | 50(399v) | 0 | 20 | 25 | 0 | 0 | 25-9 | 0.96 | - | - | - | - | no | Ning | |

| Pt | 3 | 50 | 0 | 20 | 25 | 0 | 0 | 0.82"-9 | 2.9 | - | - | - | - | no | Ning | |

| Si | 8 | 250 | 0 | 25 | 25 | 0 | 0 | 15-3 | 1.4 | - | - | - | - | no | Gerhard - ramp 2W/s - 3% Unif 4" wafer | |

| SiN | 3 | 200 | 10 | 20 | 25 | 3 | 0 | 25-9 | 1.56 | - | - | 1.992 | - | yes | Brian | |

| SiN | 3 | 250 | 10 | 20 | 25 | 2.5 | 0 | 25-9 | 2.1 | - | - | 2.06 | - | yes | Brian | |

| SiO2 | 3 | 200 | 10 | 20 | 25 | 0 | 3 | 25-9 | 3.68 | - | - | 1.447 | - | yes | Brian | |

| SiO2 | 3 | 200 | 10 | 20 | 25 | 0 | 5 | 45-3 | 2.60 | - | - | 1.471 | - | yes | Brian | |

| SiO2 | 3 | 250 | 10 | 20 | 25 | 0 | 2.5 | 25-9 | 4.3 | - | - | 1.485 | - | yes | Brian | |

| Ta | 5 | 150 | 0 | 20 | 25 | 0 | 0 | 44-4 | 9.47 | - | - | - | - | yes | Ning | |

| Ta | 5 | 75 | 0 | 20 | 25 | 0 | 0 | 44-4 | 5.03 | - | - | - | - | yes | Ning | |

| Ti | 3 | 100 | 0 | 20 | 25 | 0 | 0 | 25-9 | 1.34 | - | - | - | - | yes | Ning | |

| SampleClean-NativeSiO2 | 10 | 0 | 18 | 20 | 25 | 0 | 0 | 44-4 | - | - | - | - | - | yes | 150Volts 5 min |

Height Conversion for Older Recipes

Old recipes using the manual Height setting in millimeters can be converted to the new programmatic settings in inches as follows:

| Old (mm) | New (inches) | Typical Gun Tilt (mm) |

|---|---|---|

| 15 | ||

| 25 | 0.82 | 9 |

| 44 | 1.52 | 4 |

Interpolation plot can be found here.

Fe and Co Deposition (Sputter 3)

Cu Deposition (Sputter 3)

Mo Deposition (Sputter 3)

Ni and Ta Deposition (Sputter 3)

SiO2 Deposition (Sputter 3)

SiN Deposition (Sputter 3)

Ti Deposition (Sputter 3)

Sputter 4 (AJA ATC 2200-V)

The recipes below are given as starting points from data obtained in the nanofab. For critical depositions, calibrations are recommended. Please see the SignupMonkey page for a list of currently installed targets.

| Material | P(mT) | Power Source | Pow(W) | Sub(W) | T(C) | Ar | N2 | O2 | Height-Tilt | Rate(nm/min) | Stress(MPa) | Rs(uOhm-cm) | n@633nm | k@633nm | Data Below | Comment |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | 5 | 200 | 0 | 20 | 45 | 0 | 0 | H2.75-T5 | 4.4 | - | - | - | - | Yes | Ning Cao | |

| Al2O3 | 3 | RF4-Sw1 | 200 | 0 | 20 | 30 | 0 | 1.5 | H2.75-T5 | 5.1 | 1.64202 | 0 | partial | Demis D. John | ||

| Au | 5 | 200 | 0 | 20 | 45 | 0 | 0 | H1-T10 | 17.7 | - | - | - | - | Yes | Ning Cao | |

| Au | 10 | 300 | 0 | 20 | 45 | 0 | 0 | H2.75-T5 | 45.4 | - | - | - | - | Yes | Ning Cao | |

| Cu | 5 | 150 | 0 | 20 | 30 | 0 | 0 | H0.82-T9 | 6.7 | No (SEM available) | Ning Cao | |||||

| Nb | 4 | 250 | 0 | 20 | 30 | 0 | 0 | H2.00-T7 | 7.5 | - | - | - | - | No | ||

| Pt | 5 | 200 | 0 | 20 | 45 | 0 | 0 | H2.75-T5 | 7.4 | - | - | - | - | Yes | Ning Cao | |

| Pt | 3 | 50(439V) | 0 | 20 | 45 | 0 | 0 | H2.75-T5 | 3.9 | - | - | - | - | Yes | Ning Cao | |

| Ru | 3 | 200 | 45 | H2.75-T4 | ~10 | Yes | Ning Cao | |||||||||

| Ti | 10 | 200 | 0 | 20 | 45 | 0 | 0 | H2.75-T5 | 2.3 | - | - | - | - | Yes | Ning Cao | |

| TiN | 3 | 150 | 110V | 20 | 48.25 | 1.75 | 0 | H2.5-T5 | 2 | - | 60 | - | - | No | ||

| TiO2 | 3 | 250(RF:450V) | 0 | 20 | 45 | 0 | 3 | H2.75-T5 | 4.3 | - | - | - | Yes | Ning Cao | ||

| TiW | 4.5 | 200 | 0 | 20 | 45 | 0 | 0 | H1-T10 | 4.7 | - | - | - | - | Yes | Ning Cao | |

| TiW | 4.5 | 300 | 0 | 75 | 45 | 0 | 0 | H2.75-T5 | 9.5 | -150 to 150 | 60 | - | - | Yes | 10%Ti by Wt | |

| W | 3 | 300 | 0 | 50 | 45 | 0 | 0 | H2.75-T5 | 11.5 | -150 to 150 | 11 | - | - | Yes | Jeremy Watcher |

Au Deposition (Sputter 4)

Al Deposition (Sputter 4)

Al2O3 Deposition (Sputter 4)

- Rate: 5.134 nm/min

- Cauchy Refractive Index Params (fit from λ=190-1700nm, indicating transparency over this range)

- A = 1.626

- B = 5.980E-3

- C = 1.622E-4

Pt Deposition (Sputter 4)

Ru Deposition (Sputter 4)

- Ruthenium Hardmask for SiO2 Etching - Full Process Traveler by Ning Cao

- Deposition Rate ~10nm/min

- See Fluorine-ICP > SiO2 Etching page for more info.

Ti-Au Deposition (Sputter 4)

TiO2 Deposition (Sputter 4)

TiW Deposition (Sputter 4)

W-TiW Deposition (Sputter 4)

Sputter 5 (AJA ATC 2200-V)

The recipes below are given as starting points from data obtained in the nanofab. For critical depositions, calibrations are recommended.

Please see the SignupMonkey page for a list of currently installed targets.

| Material | P(mT) | Power Source | Pow(W) | Sub(V) | T(C) | Ar | N2 | O2 | Height-Tilt | Rate(nm/min) | Stress(MPa) | Rs(uOhm-cm) | Rq(nm) | n@633nm | k@633nm | LPDb/LPDa* | Data Below | Comment |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | 5 | 250 | 0 | 20 | 45 | 0 | 0 | H1-T10 | 2.5 | 22 | No (SEM available) | Ning | ||||||

| Al2O3 | 1.5 | DC5-SW1 | 150 | - | - | 45 | - | 5 | H2.75-T5 | 5.3 | ? | ? | ? | 1.641 | - | ? | No | Demis 2018-04-13 |

| SiO2 | 3 | 250 | 120 | 20 | 45 | 0 | 2 | H1.0-T10 | 2.32 | - | - | 1.49 | - | 153/6384 | No | Biljana | ||

| SiO2 | 3 | 250 | 120 | 20 | 45 | 0 | 4.5 | H1.0-T10 | 2.29 | -515 | - | 0.210 | 1.49 | 138/4445 | No ( AFM available) | Biljana | ||

| SiO2 | 3 | 250 | 120 | 20 | 45 | 0 | 6 | H1.0-T10 | 2.32 | - | - | 1.49 | - | 27/1515 | Yes | Biljana |

*LPD: light particle detection:

- LPDb: light particle detection before deposition

- LPDa: light particle detection after deposition

SiO2 Deposition (Sputter 5)

Ion Beam Deposition (Veeco NEXUS)

- IBD Calibrations Spreadsheet - Records of historical film depositions (rates, indices), Uniformity etc.

- All users are required to enter their calibration deps (simple test deps only)

- Particulates in SiO2 and Ta2O5 in 2015

SiO2 deposition (IBD)

- SiO2 Standard Recipe

- SiO2 Data December 2014

- SiO2 Thickness uniformity 2014

- SiO2 Data-15min depositions 2015

- SiO2 Thickness uniformity-15 min depositions 2015

- SiO2 Data-1hr depositions 2015

- SiO2 Thickness uniformity-1hr depositions 2015

- SiO2 Data-1hr depositions 2016

- SiO2 Thickness uniformity-1hr depositions 2016

SiO2 1hr deposition properties:

- Dep.rate: ≈ 5.2 nm/min (users must calibrate this prior to critical deps)

- HF e.r.~350 nm/min

- Stress ≈ -390MPa (compressive)

- Refractive Index: ≈ 1.494

- [Cauchy Parameters] (350-2000nm):

- A = 1.480

- B = 0.00498

- C = -3.2606e-5

Si3N4 deposition (IBD)

- Deposition Rate: ≈ 4.10 nm/min (users must calibrate this prior to critical deps)

- HF e.r.~11nm/min

- Stress ≈ -1590MPa (compressive)

- Refractive Index: ≈ 1.969

- [Cauchy Parameters] (350-2000nm):

- A = 2.000

- B = 0.01974

- C = 1.2478e-4

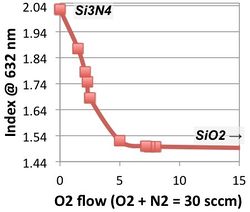

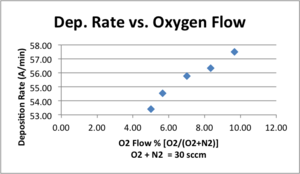

SiOxNy deposition (IBD)

These are some old (2010), initial characterizations only. A recipe improvement would be to increase the Assist O2+N2 = 60sccm total, increasing repeatability. Contact Demis for more info.

Ta2O5 deposition (IBD)

- Ta2O5 Data December-15 min depositions 2015

- Ta2O5 Thickness uniformity-15 min depositions 2015

- Ta2O5 Data December-1hr depositions 2015

- Ta2O5 Thickness uniformity-1hr depositions 2015

- Ta2O5 Data December-1hr depositions 2016

- Ta2O5 Thickness uniformity-1hr depositions 2016

- Ta2O5 1hr depositions:

- Deposition Rate: ≈ 7.8 nm/min (users must calibrate this prior to critical deps)

- HF e.r.~2 nm/min

- Stress ≈ -232MPa (compressive)

- Refractive Index: ≈ 2.172

- [Cauchy Parameters] (350-2000nm):

- A = 2.1123

- B = 0.018901

- C = -0.016222

TiO2 deposition (IBD)

- Deposition Rate: ≈ 1.29 nm/min (users must calibrate this prior to critical deps)

- HF etch rate ~5.34nm/min

- Stress ≈ -445MPa (compressive)

- Refractive Index: ≈ 2.259

- [Cauchy Parameters] (350-2000nm):

- A = 2.435

- B = -4.9045e-4

- C = 0.01309

- Absorbing < ~350nm

Al2O3 deposition (IBD)

- Al2O3 standard recipe: 1_Al2O3_dep

- Deposition Rate: ≈ 2.05nm/min (users must calibrate this prior to critical deps)

- HF etch rate ~167nm/min

- Stress ≈ -332MPa (compressive)

- Refractive Index: ≈ 1.656

- [Cauchy Parameters] (350-2000nm):( working on)

- A =

- B =

- C =

- Absorbing < ~350nm

Sputter 2 (SFI Endeavor)

This Tool has been Disabled, and is not available for use any more! These recipes are displayed here for historical/reference purposes only.