Difference between revisions of "Rapid Thermal Processor (SSI Solaris 150)"

(Text replacement - "www.nanotech.ucsb.edu/wiki/" to "wiki.nanotech.ucsb.edu/wiki/") |

|||

| (7 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | {{WIP}} <!-- this means "Work In Progress" ---> |

||

{{tool |

{{tool |

||

|super = Brian Lingg |

|super = Brian Lingg |

||

| Line 12: | Line 11: | ||

}} |

}} |

||

| − | == |

+ | ==About== |

| + | The Solaris 150 is a manual loading RTP system for R&D and pre-production. The Solaris 150 can process up to 152.4mm substrates at a temperature range from RT- 1250 degrees. The unique temperature measurement system of the Solaris requires virtually no calibration for different wafer types and backside emmissivity differences. |

||

| − | {{todo|insert basic info}} |

||

| + | The Solaris uses a unique PID process controller that ensures accurate temperature stability and uniformity. The system can accommodate four interlocked MFCs for gas mixing and forming gas processing. The Solaris is designed for silicon implant annealing and monitoring and compound semiconductor implant activation and ohmic alloying. |

||

| ⚫ | |||

| − | {{todo|list of specs, wafer sizes etc.}} |

||

| ⚫ | |||

| ⚫ | |||

| + | Wafer handling: Manual loading of wafer into the oven, single wafer processing. |

||

| ⚫ | |||

| + | |||

| ⚫ | |||

| + | Wafer sizes: 2", 3", 4", 5" and 6" wafers and pieces. |

||

| + | |||

| + | Ramp up rate: 10-200C per second, user-controllable. |

||

| + | |||

| + | Recommended steady state duration: 0-600 seconds per step. |

||

| + | |||

| + | Ramp down rate: Temperature Dependent, max 150°C per second. |

||

| + | |||

| + | Recommended steady state temperature range: 300C - 1250°C |

||

| + | |||

| + | Thermocouple temperature accuracy: + 2.5C |

||

| + | |||

| + | Temperature repeatability: + 3C or better at 1150C wafer-to-wafer. |

||

| + | |||

| + | Temperature uniformity: + 5C across a 6" (150 mm) wafer at 1150C. |

||

| + | |||

| ⚫ | |||

| + | |||

| ⚫ | |||

| ⚫ | |||

Revision as of 18:28, 6 April 2020

| |||||||||||||||||||||||

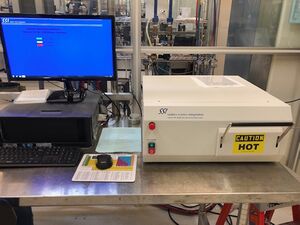

About

The Solaris 150 is a manual loading RTP system for R&D and pre-production. The Solaris 150 can process up to 152.4mm substrates at a temperature range from RT- 1250 degrees. The unique temperature measurement system of the Solaris requires virtually no calibration for different wafer types and backside emmissivity differences.

The Solaris uses a unique PID process controller that ensures accurate temperature stability and uniformity. The system can accommodate four interlocked MFCs for gas mixing and forming gas processing. The Solaris is designed for silicon implant annealing and monitoring and compound semiconductor implant activation and ohmic alloying.

Detailed Specificiations

Wafer handling: Manual loading of wafer into the oven, single wafer processing.

Wafer sizes: 2", 3", 4", 5" and 6" wafers and pieces.

Ramp up rate: 10-200C per second, user-controllable.

Recommended steady state duration: 0-600 seconds per step.

Ramp down rate: Temperature Dependent, max 150°C per second.

Recommended steady state temperature range: 300C - 1250°C

Thermocouple temperature accuracy: + 2.5C

Temperature repeatability: + 3C or better at 1150C wafer-to-wafer.

Temperature uniformity: + 5C across a 6" (150 mm) wafer at 1150C.