Difference between revisions of "Rapid Thermal Processor (AET RX6)"

(Created page with " Max temp/Time 1000C = 1 Hour 1100C = 10 min 1200C = 3 min 1300C = 10 seconds") |

|||

| Line 1: | Line 1: | ||

| + | {{tool|{{PAGENAME}} |

||

| + | |picture=PECVD1.jpg |

||

| + | |type = Vacuum Deposition |

||

| + | |super= Brian Lingg |

||

| + | |phone=(805)839-3918x210 |

||

| + | |location=Bay 3 |

||

| + | |email=lingg@ece.ucsb.edu |

||

| + | |description = PECVD Plasma Therm 790 For Oxides And Nitrides |

||

| + | |manufacturer = Plasma-Therm |

||

| + | |materials = |

||

| + | }} |

||

| + | = About = |

||

| + | Our rapid thermal annealer is manufactured by AET. Heating is achieved through two banks of heat lamps that deliver optical energy through the all-quartz chamber. With this unit, near atmospheric pressure anneals in Nitrogen, Forming Gas (10%H<sub>2</sub> / 90%N<sub>2</sub>), or Dry Air (~ 10%O<sub>2</sub> / ~ 90%N<sub>2</sub>) can be done to temperatures up to 1200°C for three minutes. An inner liner is used to prevent contamination to the main quartz chamber. A thermocouple and pyrometer are available for maintaining temperature control. The system can hold one 4-inch wafer or smaller substrates placed on top of a Silicon carrier wafer. Custom windows based control software has been added to the system by Sedona Visual Controls. All process parameters are monitored and stored. Typical anneals are done for: ohmic contact formation to semiconductors, implant activation, damage annealing, dopant activation, and film densification. A variety of materials can be annealed in the chamber, including Si, SiO<sub>2</sub>, Si<sub>3</sub>N<sub>4</sub>, GaAs, InP, GaSb, GaN, and metals. For materials that will decompose at the elevated temperatures, a dielectric anneal cap must be deposited on the wafer or an enclosed wafer holder must be used to prevent contamination of the chamber walls. |

||

| + | = Detailed Specifications = |

||

| + | *Temperatures of 1000°C for 20 min., 1100°C for 5 min., 1200°C for 1 min. Nitrogen, Forming Gas, Dry Air at flows up to 10000 lpm TC use for anneals up to 1000°C Pyrometer for temperatures above 400°C |

||

| ⚫ | |||

| + | *Windows-based process monitoring and control software by Sedona Visual Controls |

||

| ⚫ | |||

| ⚫ | |||

| + | |||

| − | 1100C = 10 min |

||

| + | {| border="1" class="wikitable" style="border: 1px solid #D0E7FF; background-color:#ffffff; text-align:center;" |

||

| − | 1200C = 3 min |

||

| + | |- |

||

| − | 1300C = 10 seconds |

||

| + | |width="100"|Temperature||width="75"|Time |

||

| + | |- |

||

| ⚫ | |||

| + | |- |

||

| + | |1100°C||10 min |

||

| + | |- |

||

| + | |1200°C ||3 min |

||

| + | |- |

||

| + | |1300°C|| 10 sec |

||

| + | |- |

||

| + | |} |

||

Revision as of 07:49, 2 July 2012

| ||||||||||||||||||||

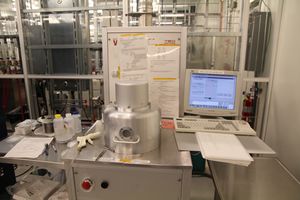

About

Our rapid thermal annealer is manufactured by AET. Heating is achieved through two banks of heat lamps that deliver optical energy through the all-quartz chamber. With this unit, near atmospheric pressure anneals in Nitrogen, Forming Gas (10%H2 / 90%N2), or Dry Air (~ 10%O2 / ~ 90%N2) can be done to temperatures up to 1200°C for three minutes. An inner liner is used to prevent contamination to the main quartz chamber. A thermocouple and pyrometer are available for maintaining temperature control. The system can hold one 4-inch wafer or smaller substrates placed on top of a Silicon carrier wafer. Custom windows based control software has been added to the system by Sedona Visual Controls. All process parameters are monitored and stored. Typical anneals are done for: ohmic contact formation to semiconductors, implant activation, damage annealing, dopant activation, and film densification. A variety of materials can be annealed in the chamber, including Si, SiO2, Si3N4, GaAs, InP, GaSb, GaN, and metals. For materials that will decompose at the elevated temperatures, a dielectric anneal cap must be deposited on the wafer or an enclosed wafer holder must be used to prevent contamination of the chamber walls.

Detailed Specifications

- Temperatures of 1000°C for 20 min., 1100°C for 5 min., 1200°C for 1 min. Nitrogen, Forming Gas, Dry Air at flows up to 10000 lpm TC use for anneals up to 1000°C Pyrometer for temperatures above 400°C

- Windows-based process monitoring and control software by Sedona Visual Controls

Max temp/Time

| Temperature | Time |

| 1000°C | 1 Hour |

| 1100°C | 10 min |

| 1200°C | 3 min |

| 1300°C | 10 sec |