Difference between revisions of "RIE 2 (MRC)"

(added SOP section) |

|||

| Line 11: | Line 11: | ||

|toolid=25 |

|toolid=25 |

||

}} |

}} |

||

| − | = |

+ | ==About== |

| Line 18: | Line 18: | ||

RIE of InP and related compounds can be achieved with a hydride-based process chemistry of methane/hydrogen with an etching mechanism due to a "reverse" metalorganic CVD reaction. Because both etching and deposition occur simultaneously, it is important to use the proper gas flows and to periodically remove any polymer reaction by-products deposited on the non-etched (mask) surfaces. (This system has an additional flow circuit in order to bleed in small amounts, <1 sccm, of O<sub>2</sub>). Alternatively, one can perform cyclic etching between MHA and O<sub>2</sub> to keep polymer formation to a minimum. With this technique selectivity is quite high and anisotropic etching can be achieved. While a metal, dielectric or photoresist may be used as a mask, photoresist should only be used at low bias voltages in order to avoid mask pattern distortions due to reflow. A precoat etch should be done before etching to condition the chamber. |

RIE of InP and related compounds can be achieved with a hydride-based process chemistry of methane/hydrogen with an etching mechanism due to a "reverse" metalorganic CVD reaction. Because both etching and deposition occur simultaneously, it is important to use the proper gas flows and to periodically remove any polymer reaction by-products deposited on the non-etched (mask) surfaces. (This system has an additional flow circuit in order to bleed in small amounts, <1 sccm, of O<sub>2</sub>). Alternatively, one can perform cyclic etching between MHA and O<sub>2</sub> to keep polymer formation to a minimum. With this technique selectivity is quite high and anisotropic etching can be achieved. While a metal, dielectric or photoresist may be used as a mask, photoresist should only be used at low bias voltages in order to avoid mask pattern distortions due to reflow. A precoat etch should be done before etching to condition the chamber. |

||

| − | = |

+ | ==Detailed Specifications== |

| − | *Etch gases include: CH<sub>4</sub>, H<sub>2</sub>, Ar and O<sub>2</sub> |

+ | *Etch gases include: CH<sub>4</sub>, H<sub>2</sub>, Ar and O<sub>2</sub> |

| − | *Low 1 E -6 ultimate chamber pressure |

+ | *Low 1 E -6 ultimate chamber pressure |

| − | *13.56 Mhz excitation frequency |

+ | *13.56 Mhz excitation frequency |

| − | *Sample size limited to approximately 2 inches |

+ | *Sample size limited to approximately 2 inches |

| − | *HeNe and IR laser monitoring for endpoint |

+ | *HeNe and IR laser monitoring for endpoint |

| − | *Automatic tuning network |

+ | *Automatic tuning network |

| − | *DC Bias or RF power control |

+ | *DC Bias or RF power control |

| − | *Masking materials include: Ni, SiON, photoresist (limited to low bias/power) |

+ | *Masking materials include: Ni, SiON, photoresist (limited to low bias/power) |

*Typical etch conditions for InGaAsP: |

*Typical etch conditions for InGaAsP: |

||

| − | **75 mT (CH<sub>4</sub>/H<sub>2</sub>/Ar : 4/20/10 sccm) |

+ | **75 mT (CH<sub>4</sub>/H<sub>2</sub>/Ar : 4/20/10 sccm) |

| − | **450v bias |

+ | **450v bias |

**~ 45 nm/min. etch rate |

**~ 45 nm/min. etch rate |

||

| + | |||

| + | == Procedures == |

||

| + | RIE #2 Standard Operating Procedure |

||

Revision as of 15:01, 11 September 2019

| |||||||||||||||||||||

About

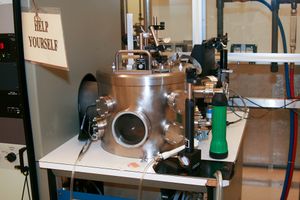

This is a Materials Research Corporation RIE-51 parallel plate, 13.56 Mhz system used primarily for the etching of InP with CH4/H2/Ar gases, although it can be used to etch As- and Sb-based III-V compounds and a variety of II-VI semiconductors as well. For Al-containing compounds and II-VI compounds, high bias power is required. Tool features include: six inch diameter water cooled cathode/substrate platform, pyrex cylinder for plasma confinement and gas flow control, adjustable cathode-anode spacing, fixed bias or power control and HeNe laser etch monitor with chart recorder. It is diffusion pumped and has no loadlock. Various etching applications have included: in-plane lasers/facets, InP-based HBTs, FET gate recessing, InP-based quantum microcavities, Bragg-Fresnel x-ray lenses and waveguides.

RIE of InP and related compounds can be achieved with a hydride-based process chemistry of methane/hydrogen with an etching mechanism due to a "reverse" metalorganic CVD reaction. Because both etching and deposition occur simultaneously, it is important to use the proper gas flows and to periodically remove any polymer reaction by-products deposited on the non-etched (mask) surfaces. (This system has an additional flow circuit in order to bleed in small amounts, <1 sccm, of O2). Alternatively, one can perform cyclic etching between MHA and O2 to keep polymer formation to a minimum. With this technique selectivity is quite high and anisotropic etching can be achieved. While a metal, dielectric or photoresist may be used as a mask, photoresist should only be used at low bias voltages in order to avoid mask pattern distortions due to reflow. A precoat etch should be done before etching to condition the chamber.

Detailed Specifications

- Etch gases include: CH4, H2, Ar and O2

- Low 1 E -6 ultimate chamber pressure

- 13.56 Mhz excitation frequency

- Sample size limited to approximately 2 inches

- HeNe and IR laser monitoring for endpoint

- Automatic tuning network

- DC Bias or RF power control

- Masking materials include: Ni, SiON, photoresist (limited to low bias/power)

- Typical etch conditions for InGaAsP:

- 75 mT (CH4/H2/Ar : 4/20/10 sccm)

- 450v bias

- ~ 45 nm/min. etch rate

Procedures

RIE #2 Standard Operating Procedure