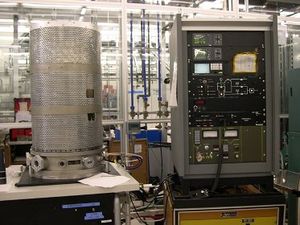

RIE 1 (Custom)

| ||||||||||||||||||||

About

The Reactive Ion Etcher #1 is a turbo-pumped plasma deposition system from Sputtered Films that has been modified by the UCSB Nanofabrication Research Facility for chlorine-based reactive ion etching @ 13.56 Mhz. Special features include: a very small volume sample loadlock (for low O2 partial pressure) with integral four inch sample holder and a HeNe laser etch monitor.

Typical materials that are etched with this system include: GaAs/AlGaAs, optical photoresists, and polymers such as polyimides. In addition, various optoelectronic devices such as in-plane lasers, vertical cavity surface emitting lasers (VCSELs), microlenses, FETs, Bragg Fresnel lenses are among the structures and devices that can be processed with this tool. This etcher is the preferred system for obtaining anisotropic etching (straight sidewalls) for the AlGaAs semiconductor system.

Detailed Specifications

- Temescal 10kV power supply

- Temescal 4-pocket series 260 e-beam source

- Electron beam controller with sweep rate and amplitude control

- Cryo-pumped system with ~ 1e-7 ultimate base pressure

- Automatic vacuum sequencing

- Crystal thickness monitoring

- Sample size: up to 3” x 3” pieces

- Oxygen bleed for maintaining oxide stoichiometry