Difference between revisions of "PECVD Recipes"

| Line 221: | Line 221: | ||

| − | ==SiN 250C deposition (Unaxis VLR)== |

+ | == SiN 250C deposition (Unaxis VLR) == |

| + | ==== Historical Data ==== |

||

| + | |||

| − | === Thin-Film Properties === |

+ | ===== Thin-Film Properties ===== |

*[https://docs.google.com/spreadsheets/d/1VrgS0cB2OcdZVTCnDAesgQCLRaAgEB_Iajc_OrhXOo0/edit#gid=sharing SiN 250C 300nm Data-2020] |

*[https://docs.google.com/spreadsheets/d/1VrgS0cB2OcdZVTCnDAesgQCLRaAgEB_Iajc_OrhXOo0/edit#gid=sharing SiN 250C 300nm Data-2020] |

||

| − | === Uniformity Data === |

+ | ===== Uniformity Data ===== |

*[https://docs.google.com/spreadsheets/d/1YAx_Ix84xId8CAhDwZeFT7jLFUwg-BET9aBwg3DxUmQ/edit#gid=sharing Thickness Uniformity SiN 250C 300nm-2020] |

*[https://docs.google.com/spreadsheets/d/1YAx_Ix84xId8CAhDwZeFT7jLFUwg-BET9aBwg3DxUmQ/edit#gid=sharing Thickness Uniformity SiN 250C 300nm-2020] |

||

Revision as of 12:21, 21 April 2020

Back to Vacuum Deposition Recipes.

PECVD 1 (PlasmaTherm 790)

Historical Particulate Data

- Particulates(Gain4) in PECVD#1-OLD DATA 2015

- Particulates(Gain4) in PECVD#1-OLD DATA 2016

- Particulates(Gain4) in PECVD#1-OLD DATA 2017

- Particulates in PECVD#1 films 2017

- Particulates in PECVD#1 films 2018

- Particulates in PECVD#1 films 2019

- Particulates in PECVD#1 films 2020

SiN deposition (PECVD #1)

Historical Data

Thin-Film Properties

- SiN 100nm Data 2014

- SiN 100nm Data 2015

- SiN 100nm Data 2016

- SiN 100nm Data 2017

- SiN 300nm Data 2017

- SiN 300nm Data 2018

- SiN 300nm Data 2019

- SiN 300nm Data 2020

Uniformity Data

- SiN 100 nm Thickness uniformity 2014

- SiN 100 nm Thickness uniformity 2015

- SiN 100 nm Thickness uniformity 2016

- SiN 100 nm Thickness uniformity 2017

- SiN 300nm Thickness uniformity 2017

- SiN 300nm Thickness uniformity 2018

- SiN 300nm Thickness uniformity 2019

- SiN 300nm Thickness uniformity 2020

SiO2 deposition (PECVD #1)

Historical Data

Thin-Film Properties

- SiO2 100nm Data 2014

- SiO2 100nm Data 2015

- SiO2 100nm Data 2016

- SiO2 100nm Data 2017

- SiO2 300nm Data 2017

- SiO2 300nm Data 2018

- SiO2 300nm Data 2019

- SiO2 300nm Data 2020

Uniformity Data

- SiO2 100nm Thickness uniformity 2014

- SiO2 100 nm Thickness uniformity 2015

- SiO2 100 nmThickness uniformity 2016

- SiO2 100nm Thickness uniformity 2017

- SiO2 300nm Thickness uniformity 2017

- SiO2 300nm Thickness uniformity 2018

- SiO2 300nm Thickness uniformity 2019

- SiO2 300nm Thickness uniformity 2020

Low-Stress SiN - LS-SiN (PECVD#1)

SiOxNy deposition (PECVD #1)

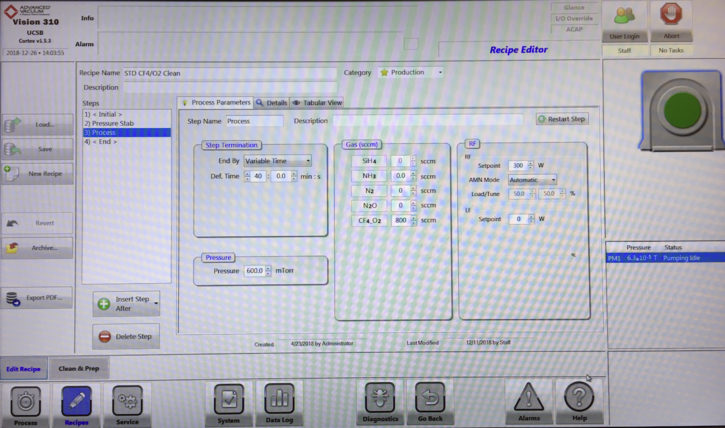

Cleaning Recipes (PECVD #1)

The cleaning procedure is very important in order to have consistent result on this tool and also to keep particulate count low. After each deposition you should clean the tool following instructions carefully. The clean is done in two steps:

- Wet cleaning (start cleaning by using a cleanroom wipe sprayed with DI. Wipe chamber sidewalls with it. Finish cleaning by using the cleanroom wipe sprayed with IPA. )

- Load the recipe for cleaning " CF4/O2 Clean" (edit the recipe and change ONLY time of cleaning). Follow instructions regarding a required time for cleaning.

" CF4/O2 Clean recipe"

PECVD 2 (Advanced Vacuum)

Historical Particulate Data

- Particulates (Gain4) in PECVD#2 2015

- Particulates (Gain4) in PECVD#2 2016

- Particulates (Gain4) in PECVD#2 2017

- Particulates in PECVD#2 films 2017

- Particulates in PECVD#2 films 2018

- Particulates in PECVD#2 films 2019

- Particulates in PECVD#2 films 2020

SiO2 deposition (PECVD #2)

Standard Recipe

Historical Data

Thin-Film Properties

- Oxide Data 2014

- Oxide Data 2015

- Oxide data 2016

- Oxide Data 2017

- Oxide Data 2018

- Oxide Data 2019

- Oxide Data 2020

Uniformity Data

- Oxide Thickness Uniformity 2014

- Oxide Thickness Uniformity 2015

- Oxide Thickness Uniformity 2016

- Oxide Thickness Uniformity 2017

- Oxide Thickness Uniformity 2018

- Oxide Thickness Uniformity 2019

- Oxide Thickness Uniformity 2020

SiN deposition (PECVD #2)

Standard Recipe

Historical Data

Thin-Film Properties

- Nitride2 Data 2014

- Nitride2 Data 2015

- Nitride2 Data 2016

- Nitride2 Data 2017

- Nitride2 Data 2018

- Nitride2 Data 2019

- Nitride2 Data 2020

Uniformity Data

- Nitride2 Thickness Uniformity 2014

- Nitride2 Thickness Uniformity 2015

- Nitride2 Thickness Uniformity 2016

- Nitride2 Thickness Uniformity 2017

- Nitride2 Thickness Uniformity 2018

- Nitride2 Thickness Uniformity 2019

- Nitride2 Thickness Uniformity 2020

Low-Stress SiN deposition (PECVD #2)

Low-Stress SilIcon Nitride (< 100 MPa)

Standard Recipe

- STD LS Nitride2 Recipe Parameters

- STD LS Nitride2 Recipe

- Old Versions:

Historical Data

Thin-Film Properties

- LS Nitride2 Data 2014

- LS Nitride2 Data 2015

- LS Nitride2 Data 2016

- LS Nitride2 Data 2017

- LS Nitride2 Data 2018

- LS Nitride2 Data 2019

- LS Nitride2 Data 2020

Uniformity Data

- LS Nitride2 Thickness Uniformity 2014

- LS Nitride2 Thickness Uniformity 2015

- LS Nitride2 Thickness Uniformity 2016

- LS Nitride2 Thickness Uniformity 2017

- LS Nitride2 Thickness Uniformity 2018

- LS Nitride2 Thickness Uniformity 2019

- LS Nitride2 Thickness Uniformity 2020

Amorphous-Si deposition (PECVD #2)

Cleaning Recipes (PECVD #2)

The cleaning procedure is very important in order to have consistent result on this tool and also to keep particulate count low. After each deposition you should clean the tool following instructions carefully. The clean is done in two steps:

- Wet cleaning (start cleaning by using a cleanroom wipe sprayed with DI. Wipe chamber sidewalls with it. Finish cleaning by using the cleanroom wipe sprayed with IPA. )

- Load the recipe for cleaning " STD CF4/O2 Clean" (edit the recipe and change ONLY time of cleaning). Follow instructions regarding a required time for cleaning.

" STD CF4/O2 Clean recipe"

ICP-PECVD (Unaxis VLR)

Historical Particulate Data

Sandard Recipes

SiN 250C deposition (Unaxis VLR)

Historical Data

Thin-Film Properties

Uniformity Data

SiN LS 250C Deposition (Unaxis VLR)

Thin-Film Properties

Uniformity Data

SiO2 250C Deposition (Unaxis VLR)

Thin-Film Properties

- SiO2 LDR 250C 300nm Data-2019

- SiO2 LDR 250C 300nm Data-2020

- SiO2 HDR 250C 300nm Data-2019

- SiO2 HDR 250C 300nm Data-2020

Uniformity Data

- Thickness Uniformity SiO2 LDR 250C 300nm-2019

- Thickness Uniformity SiO2 LDR 250C 300nm-2020

- Thickness Uniformity SiO2 HDR 250C 300nm-2019

- Thickness Uniformity SiO2 HDR 250C 300nm-2020

Cleaning Recipes (Unaxis VLR Dep)

You must edit the Post-Dep Clean recipe to correspond to your deposited thickness and material. See the Operating Procedure on the Unaxis Tool Page for details.

- SiNx etches at 20nm/min

- SiO2 etches at 40nm/min

" Post-Dep Clean" recipe

Add the picture of " Post-Dep Clean" recipe