Difference between revisions of "PECVD 2 (Advanced Vacuum)"

Jump to navigation

Jump to search

(→Recipes: mention historical data) |

|||

| (18 intermediate revisions by one other user not shown) | |||

| Line 19: | Line 19: | ||

* Recipes for SiO2, Si3N4 and Low-Stress Si3N4 can be found on the PECVD Recipes Page: |

* Recipes for SiO2, Si3N4 and Low-Stress Si3N4 can be found on the PECVD Recipes Page: |

||

** [[PECVD Recipes#PECVD 2 .28Advanced Vacuum.29|Recipes > Vacuum Deposition Recipes > PECVD Recipes > '''PECVD 2 - Advanced Vacuum''']] |

** [[PECVD Recipes#PECVD 2 .28Advanced Vacuum.29|Recipes > Vacuum Deposition Recipes > PECVD Recipes > '''PECVD 2 - Advanced Vacuum''']] |

||

| + | ** Historical Data is also shown here. |

||

* A list of all available deposited films can be found on the Vacuum Deposition Recipes page: |

* A list of all available deposited films can be found on the Vacuum Deposition Recipes page: |

||

** [[Vacuum Deposition Recipes|Recipes > Vacuum Deposition Recipes]] |

** [[Vacuum Deposition Recipes|Recipes > Vacuum Deposition Recipes]] |

||

| Line 27: | Line 28: | ||

== Documentation == |

== Documentation == |

||

| + | * |

||

| − | * Standard Operating Instrustions |

||

| + | * |

||

| ⚫ | |||

| + | * |

||

| − | * For particle count data |

||

| + | * |

||

| + | * |

||

| + | * |

||

| + | * |

||

| + | * |

||

| + | * |

||

| + | * |

||

| + | * [https://wiki.nanotech.ucsb.edu/w/images/2/2c/SOP_for_Advanced_Vacuum_PECVD.pdf Operating Instructions] |

||

| ⚫ | |||

| + | * For particle counting method, see the [[Wafer scanning process traveler|Surfscan Scanning Procedure]] |

||

Revision as of 10:03, 16 February 2021

| |||||||||||||||||||||

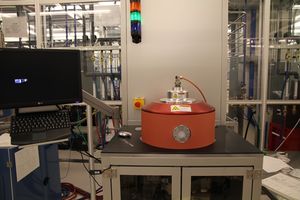

About

This open-load system is dedicated to PECVD of SiO2, SiNx, SiOxNy, and a-Si using Silane (2%SiH4, 98% He), N2O, NH3, and N2 gases. The sample electrode has a 270mm diameter useable area, allowing for multiple 4” wafer depositions in a single run. Standard operating temperature is 300C, but can be user changed for temps ranging anywhere from 250 to 350C. The system is equipped with a dual generator, dual frequency option for growth of low-stress Nitride films.

Recipes

- Recipes for SiO2, Si3N4 and Low-Stress Si3N4 can be found on the PECVD Recipes Page:

- Recipes > Vacuum Deposition Recipes > PECVD Recipes > PECVD 2 - Advanced Vacuum

- Historical Data is also shown here.

- A list of all available deposited films can be found on the Vacuum Deposition Recipes page:

See Also

Documentation

- Operating Instructions

- Wafer Coating Process Traveler

- For particle counting method, see the Surfscan Scanning Procedure