Difference between revisions of "Nick test"

(Created page with "{{tool|{{PAGENAME}} |picture=PECVD1.jpg |type = Vacuum Deposition |super= Don Freeborn |phone=(805)839-7975 |location=Bay 3 |email=dfreeborn@ucsb.edu |description = PECVD Plas...") |

|||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | {{ |

+ | {{tool2|{{PAGENAME}} |

|picture=PECVD1.jpg |

|picture=PECVD1.jpg |

||

|type = Vacuum Deposition |

|type = Vacuum Deposition |

||

|super= Don Freeborn |

|super= Don Freeborn |

||

| + | |super2= Tony Bosch |

||

|phone=(805)839-7975 |

|phone=(805)839-7975 |

||

|location=Bay 3 |

|location=Bay 3 |

||

Latest revision as of 22:15, 23 August 2021

| ||||||||||||||||||||||||||||||

About

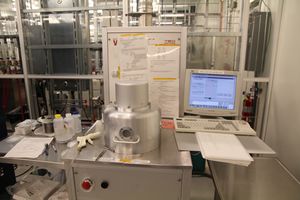

This is a Plasma-Therm model 790 plasma enhanced chemical vapor deposition system for depositing SiO2, Si3N4, or SiOxNy dielectric films. The system uses a capacitively-coupled 13.56 MHz source excitation to produce the plasma between two parallel aluminum plates. The gas is injected over the sample through a 6” diameter showerhead. The samples are placed on the system anode (to minimize ion damage) which is heated to 250-350°C. SiO2 is produced from SiH4/He 2%/98% and N2O at 250°C. The typical deposition rate is 400 A/min. at 300 mT pressure. The typical BOE etch rate of this oxide is about 400 nm/min. Si3N4 is produced from SiH4/He 2%/98% and NH3 at 250°C or 350°C. The more dense films are produced at 350°C. The stress of the nitride can be altered by adjusting the N2:He ratio of the deposition. CF4/O2 plasmas are used to clean the chamber between depositions.

These films are typically used for capacitor dielectrics, chemical passivation layers, electrical insulators, reactive ion etching masks, and optical anti-reflective coatings. The system is fully programmable with windows-based software and has a wide array of pre-defined thicknesses. Custom programs for dielectric stacks or different process parameters can be written and saved.

Detailed Specifications

- Gases used: NH3, N2O, 2%SiH4/He, N2,CF4 and O2

- ~ 10mT ultimate chamber pressure

- 13.56 Mhz excitation freq.

- Sample size: pieces to 6” wafers

- Automatic tuning network

- RF Power control

- Full computer operation

- Standard recipes for a variety of film thicknesses

Documentation

- Operating Instructions

- Wafer Coating Process Traveler

- For particle counting method, see the Surfscan Scanning Procedure

Recipes & Process Data

- Historical Characterization Data & Standard Recipes can be found at: Recipes > Deposition > PECVD1