Difference between revisions of "Maskless Aligner (Heidelberg MLA150)"

(link to MLA150 recipes) |

(→Design Tools/Info: Added substrate template rules visual aid) |

||

| (23 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | {{WIP}} |

||

{{tool|{{PAGENAME}} |

{{tool|{{PAGENAME}} |

||

| − | |picture= |

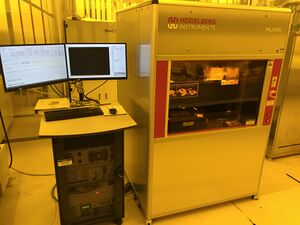

+ | |picture=MLA150_Heidelberg_Bay_6_Photo.jpg |

|type = Lithography |

|type = Lithography |

||

|super = Biljana Stamenic |

|super = Biljana Stamenic |

||

|location = Bay 6 |

|location = Bay 6 |

||

| − | |description = Maskless I-Line Photolithography |

+ | |description = Direct-Write (Maskless) I-Line Photolithography |

| − | |manufacturer = Heidelberg Instruments |

+ | |manufacturer = [https://heidelberg-instruments.com Heidelberg Instruments] |

|model = MLA150 |

|model = MLA150 |

||

| + | |toolid=32 |

||

|materials = I-Line Photoresists |

|materials = I-Line Photoresists |

||

}} |

}} |

||

==About== |

==About== |

||

| − | The MLA150 allows for arbitrary direct patterning of I-Line photoresists |

+ | The MLA150 allows for arbitrary direct-write patterning of I-Line photoresists from an uploaded CAD drawing/file (GDS, DXF, CIF etc.). The system uses a [https://en.wikipedia.org/wiki/Digital_micromirror_device digital micromirror device] ("DMD", an array of MEMS mirrors) for patterning the exposure light-field, to programmatically expose digitized patterns directly onto the sample - no glass photomasks/reticles are required. |

| + | |||

| + | Depending on the exposure options and write area, the MLA is able to expose a 100mm wafer in about 30min, and achieves minimum features sizes around 0.5µm, with overlay/alignment accuracy better than 200nm. |

||

| + | |||

| + | The system has a continuous, automatic autofocus, using pneumatic and optical detection. This potentially enables lithography on non-planar or curved substrates. |

||

| + | |||

| + | The software allows for custom drawings and aligment marks to be exposed onto any feature located on the microscope. |

||

| + | |||

| + | Greyscale lithography allows for photoresist profiles with repeatable slanted or tapered structures, via an 8-bit greyscale bitmap or layer-structured DXF file. |

||

| + | |||

| + | The high-aspect ratio (variable/long focal length) option enables vertical sidewalls on very thick (~100µm) photoresists. |

||

==Detailed Specifications== |

==Detailed Specifications== |

||

| + | *Maximum Writeable Area: 150 x 150mm |

||

| − | *Wafer size: |

||

| + | *Substrate size: 9-inch square or 200mm round down to 5-mm pieces |

||

| − | *Wafer / substrate thickness: |

+ | *Wafer / substrate thickness: Max. 9mm / Min. 0.1mm |

*Exposure optics: |

*Exposure optics: |

||

| + | **[https://en.wikipedia.org/wiki/Digital_micromirror_device Digital micromirror device (DMD)] |

||

| ⚫ | |||

| − | **Laser # |

+ | **Laser #1: 375nm |

| ⚫ | |||

| − | * Focus modes: |

||

| + | **Lens NA = 0.95 |

||

| − | * Alignment: |

||

| + | * Alignment Accuracy: Global ≤ 500nm; Local ("Field") ≤ 250nm |

||

| − | ** Modes? |

||

| + | * Linewidth variation: ≤100nm (relevant to stitched exposure fields) |

||

| − | ** Accuracy: |

||

| + | * Write Grid (Address Unit): |

||

| − | ** Repetability |

||

| + | ** High Quality Mode (std.): 40nm |

||

| + | ** Fast Mode: 100nm |

||

| − | *Additional manufacturer options |

+ | *Additional manufacturer options: |

| − | ** |

+ | **High-resolution option (Write Mode 1) |

| + | **Extended Focus Range |

||

| − | **Dual lasers? |

||

| + | ** Variable Focal Depth |

||

| − | **High-resolution option? |

||

| + | ** Optical (laser) Autofocus in addition to std. Pneumatic Autofocus |

||

| + | ** Greyscale Mode |

||

| + | ** (No backside alignment) |

||

| ⚫ | |||

| + | [[File:MLA150 Spatial Light Modulator Description.png|alt=Schematic of spatial light modulator exposure technique.|none|thumb|550x600px|Exposure method using a spatial light modulator and continuously moving stage. See [https://heidelberg-instruments.com/en/features-technologies/key-features/maskless-lithography.html HIMT] for more info.]] |

||

| + | === Operating Procedures === |

||

| − | * Uniformity: |

||

| + | *[https://wiki.nanotech.ucsb.edu/w/images/5/56/MLA150_SOP_Rev_I_%28LS%29.pdf MLA150 - Standard Operating Procedure] - updated Apr 26th 2021 |

||

| − | * Write speeds: |

||

| + | **''Includes File-upload procedure, CAD Conversion, Exposure and Alignment.'' |

||

| + | *[[MLA150 - Large Image GDS Generation|Large Image Patterning]] - one way to generate a GDS file out of an arbitrary image (eg. JPG, BMP, PNG etc.) |

||

| + | === Video Trainings === |

||

| + | '''Important:''' You must be <u>authorized by a supervisor</u> to use the tool! The video below is provided for reference only, and does not substitute training by NanoFab staff. |

||

| + | * [https://gauchocast.hosted.panopto.com/Panopto/Pages/Viewer.aspx?id=5813cf18-37cb-48f1-aee6-acd50055c65e Heidelberg MLA150 Training Video (v2, on GauchoSpace/Panopto)] |

||

| + | === [[MLA150 - Troubleshooting|<u>Troubleshooting & Known Bugs</u>]] === |

||

| ⚫ | |||

| + | * See the linked page for troubleshooting/recovery info and workarounds to known bugs. |

||

| − | *[[MLA150 - Standard Operating Procedure]] |

||

== Design Tools/Info == |

== Design Tools/Info == |

||

* [[MLA150 - Design Guidelines]] |

* [[MLA150 - Design Guidelines]] |

||

* [[MLA150 - CAD Files and Templates]] |

* [[MLA150 - CAD Files and Templates]] |

||

| + | * [https://wiki.nanotech.ucsb.edu/w/images/4/48/MLA150_Substrate_Template_Rules.pdf MLA150 - Substrate Template Guidelines] |

||

== Recipes == |

== Recipes == |

||

| − | * '''Recipes > Lithography >''' |

+ | * '''Recipes > Lithography >''' '''<u>[[Maskless Aligner Recipes#Maskless Aligner .28Heidelberg MLA150.29|Maskless Aligner MLA150]]</u>''' |

** ''Starting recipes for various I-Line photoresists'' |

** ''Starting recipes for various I-Line photoresists'' |

||

Revision as of 13:19, 19 July 2021

|

About

The MLA150 allows for arbitrary direct-write patterning of I-Line photoresists from an uploaded CAD drawing/file (GDS, DXF, CIF etc.). The system uses a digital micromirror device ("DMD", an array of MEMS mirrors) for patterning the exposure light-field, to programmatically expose digitized patterns directly onto the sample - no glass photomasks/reticles are required.

Depending on the exposure options and write area, the MLA is able to expose a 100mm wafer in about 30min, and achieves minimum features sizes around 0.5µm, with overlay/alignment accuracy better than 200nm.

The system has a continuous, automatic autofocus, using pneumatic and optical detection. This potentially enables lithography on non-planar or curved substrates.

The software allows for custom drawings and aligment marks to be exposed onto any feature located on the microscope.

Greyscale lithography allows for photoresist profiles with repeatable slanted or tapered structures, via an 8-bit greyscale bitmap or layer-structured DXF file.

The high-aspect ratio (variable/long focal length) option enables vertical sidewalls on very thick (~100µm) photoresists.

Detailed Specifications

- Maximum Writeable Area: 150 x 150mm

- Substrate size: 9-inch square or 200mm round down to 5-mm pieces

- Wafer / substrate thickness: Max. 9mm / Min. 0.1mm

- Exposure optics:

- Digital micromirror device (DMD)

- Laser #1: 375nm

- Laser #2: 405nm

- Lens NA = 0.95

- Alignment Accuracy: Global ≤ 500nm; Local ("Field") ≤ 250nm

- Linewidth variation: ≤100nm (relevant to stitched exposure fields)

- Write Grid (Address Unit):

- High Quality Mode (std.): 40nm

- Fast Mode: 100nm

- Additional manufacturer options:

- High-resolution option (Write Mode 1)

- Extended Focus Range

- Variable Focal Depth

- Optical (laser) Autofocus in addition to std. Pneumatic Autofocus

- Greyscale Mode

- (No backside alignment)

Documentation

Operating Procedures

- MLA150 - Standard Operating Procedure - updated Apr 26th 2021

- Includes File-upload procedure, CAD Conversion, Exposure and Alignment.

- Large Image Patterning - one way to generate a GDS file out of an arbitrary image (eg. JPG, BMP, PNG etc.)

Video Trainings

Important: You must be authorized by a supervisor to use the tool! The video below is provided for reference only, and does not substitute training by NanoFab staff.

Troubleshooting & Known Bugs

- See the linked page for troubleshooting/recovery info and workarounds to known bugs.

Design Tools/Info

Recipes

- Recipes > Lithography > Maskless Aligner MLA150

- Starting recipes for various I-Line photoresists