Difference between revisions of "Lift-Off with DUV Imaging + PMGI Underlayer"

(initial process) |

(corrected typo) |

||

| (17 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| + | Developed by Demis D. John, ~2017-2019 |

||

| − | This process is intended for Deep-UV Exposure on the ASML DUV Stepper. PMGI is used as the underlayer. This process uses PMGI SF-5, which spins to about 130nm (maximum metal thickness ≈ 130nm/3 = 45nm) and undercuts laterally about 130-140nm (minimum gap between metals = (2 x 140nm) + 30nm ≈ 350nm). |

||

| + | This process is intended for Deep-UV Exposure on the ASML DUV Stepper. PMGI is used as the underlayer, which is exposed at the same time as the imaging resist. |

||

| + | Adjust spin speed or switch to a different PMGI formulation to tailor the underlayer thickness to your desired metal thickness. |

||

| − | == Tips == |

||

| − | Please see our [[https://www.nanotech.ucsb.edu/wiki/index.php/Lithography_Recipes#Lift-Off_Techniques Bi-Layer Lift-Off Tutorial]] to understand the limitations and requirements for good lift-off. |

||

| + | ==Tips== |

||

| − | * Remember that gaps in between adjacent metal traces can lift-off during the develop! |

||

| + | Please see our [https://wiki.nanotech.ucsb.edu/w/images/b/bc/Liftoff-Techniques.pdf Bi-Layer Lift-Off Tutorial] to understand the limitations and requirements for good lift-off. |

||

| + | *Remember that gaps in between adjacent metal traces can lift-off during the develop! |

||

| − | * Need underlayer thickness 2x to 3x the desired metal thickness. |

||

| − | * |

+ | *Need underlayer thickness approx. 2x the desired metal thickness. |

| + | *The underlayer will develop laterally from both sides which can lift-off the imaging resist, so: |

||

| − | ** Minimum gap between adjacent metals should then be: less than 0.5 * underlayer thickness. |

||

| + | **Minimum gap between adjacent metals should then be: ''greater than 0.5 * underlayer thickness'' |

||

| + | **Want at least 30-50nm of underlayer width left to support the imaging resist, so the PR doesn't fall over/collapse. |

||

| + | *Make sure to use a vertical evaporation line-of-sight such as [[E-Beam 4 (CHA)|EBeam4]] or [[E-Beam 1 (Sharon)|EBeam1]]. [[E-Beam 3 (Temescal)|EBeam3]] is not vertical unless special care is taken. |

||

| − | * Want at least 30-50nm of underlayer left so the PR doesn't fall over/collapse. |

||

| + | ===Process Limits=== |

||

| − | * Also make sure to use a very vertical evaporation - EBeam4 or EBeam1. EBeam3 is not vertical. |

||

| + | This process is written with PMGI SF-5 @ 4krpm, which spins to about 130nm |

||

| + | *<u>Maximum metal thickness</u> = 130nm/2 ≈ '''65nm''' (can possibly increase up to 130nm* 2/3 ≈ 85nm) |

||

| + | *Undercuts laterally about 130-140nm, so <u>minimum gap between metals</u> = (2 x 140nm) + ~30nm ≈ '''350nm''' |

||

| + | Adjust the PMGI layer thickness to adjust these process limits. |

||

| − | == Suggested process for Liftoff == |

||

| + | PMGI could be spun thicker, or double-spun to get thicker underlayers (develop time & undercut will increase accordingly). |

||

| − | De-H2O Bake (eg. 220°C, 1m+). Optionally Oxygen ash instead. |

||

| + | PMGI underlayer could be replaced with LOL1000/LOL2000, or another developable underlayer. |

||

| − | HMDS soak 10s+ |

||

| + | ==Suggested Process for Liftoff== |

||

| − | Spin PMGI SF-5 @ 4krpm (rcp 7) |

||

| + | {| class="wikitable" |

||

| + | |De-H2O Bake (eg. 220°C, 1m+) |

||

| + | - or - |

||

| + | Technics O2 ash (300mT, 100W), 15sec |

||

| + | |Oxygen ash is faster and more effective |

||

| + | |- |

||

| + | |Spin PMGI SF-5 @ 4krpm (rcp 7) |

||

| + | | |

||

| + | |- |

||

| + | |POLOS underside clean: 2000rpm, ACE/ISO/N2 |

||

| + | | |

||

| + | |- |

||

| + | |PMGI-Bake: 220°C, 3min (BrewerSci lift-pin hotplate). |

||

| + | |Can just place wafer directly onto hotplate surface. |

||

| + | Optionally can use lift-pins & Recipe "'''00 220deg, 3min Vac'''"; |

||

| − | + | --> To prevent wafer sliding: Enable Vacuum with overhead valve, only for wafer landing and then turn off. |

|

| + | |- |

||

| + | |Spin UV-6-0.8 @ rcp 6 (3.5krpm) |

||

| + | | |

||

| + | |- |

||

| + | |POLOS underside clean: 2000rpm, ACE/ISO/N2 |

||

| + | | |

||

| + | |- |

||

| + | |Soft-Bake = 135°C, 1min (builtin hotplate) |

||

| + | | |

||

| + | |- |

||

| + | |(check underside for particulates) |

||

| + | | |

||

| + | |- |

||

| + | |'''<u>ASML Exposure</u>''' |

||

| + | | |

||

| + | |- |

||

| + | |Default: Exp = 37.5mJ // foc = –0.10 |

||

| + | |Try this exposure dose but might need to do a FocArray (smaller Image Distribution eg. 5x5) to find proper exposure. |

||

| + | |- |

||

| + | |PEB = 135°C, 1.5min (built-in hotplate) |

||

| + | | |

||

| + | |- |

||

| + | |Dev (300MiF) = 50sec (CRITICAL time) |

||

| + | |Use cassette & H2O rinse dish prepared |

||

| + | --> not stirring, instead very slow/gentle lift/drop at various angles or gentle swish just to mix developer slightly. |

||

| + | |- |

||

| + | |DI rinse |

||

| + | |Very Gently! Dunk into prepared DI dish, and dump/fill gently 2x. Don’t allow direct hard water to hit PR surface. |

||

| + | |- |

||

| + | |PEii Technics O2: 30sec (100W/300mT) |

||

| + | |May increase feature size openings by ~50nm. |

||

| + | |- |

||

| + | |'''<u>Metal Evaporation</u>''' |

||

| + | (insert steps) |

||

| + | |EBeam#4 or EBeam#1 with vertical/4-inch holders (not planetary) |

||

| + | |- |

||

| + | |'''<u>Lift-off in NMP</u>''' |

||

| + | |Facing down or vertical. |

||

| + | Optional: going directly into continuous Ultrasonic can reduce residual particles. |

||

| + | |} |

||

| + | ==Data== |

||

| − | Spin UV-6-0.8 @ rcp 6 (3.5krpm) |

||

| + | • For PMGI Baked at 220°C for 3min, the PMGI dissolves in AZ 300MIF at a rate of approximately ~600nm/min. |

||

| + | ===Images / Examples=== |

||

| − | --> POLOS underside clean: 2000rpm, ACE/ISO/N2 |

||

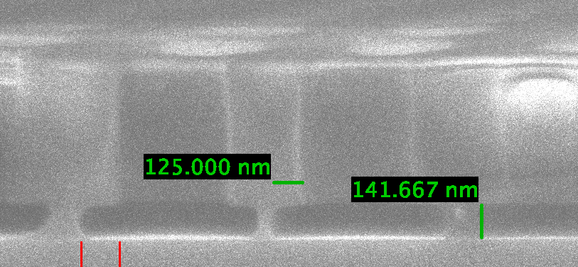

| + | [[File:PMGI+UV6 lift-off SEM - 2017-06-30 DJ.png|alt=SEM of PR cross-section|none|thumb|578x578px|SEM of holes in PR with above process. Top layer is UV6, 140nm underlayer is PMGI, substrate is Silicon. Lateral measurement of undercut is only approximate because circle may not have been cut through the exact diameter. (Demis D. John, 2017)]] |

||

| − | |||

| + | <br /> |

||

| − | Pre-Bake = 135°C, 1min (builtin hotplate) |

||

| − | |||

| − | (check underside for particulates) |

||

| − | |||

| − | ASML Exposure |

||

| − | |||

| − | -- Default: Exp = 37.5mJ // foc = –0.10 |

||

| − | |||

| − | (Try this exposure dose - might need to do a FocArray (smaller Image Distribution eg. 5x5) to find proper exposure. |

||

| − | |||

| − | PEB = 135°C, 1.5min (built-in hotplate) |

||

| − | |||

| − | Dev (300MiF) = 50sec (CRITICAL time) |

||

| − | |||

| − | --> with cassette & H2O dish prepared |

||

| − | |||

| − | --> not stirring, instead very slow/gentle lift/drop at various angles or gentle swish |

||

| − | |||

| − | DI rinse : very Gently! Dunk into prepared DI dish, and dump/fill gently 2x. Don’t allow direct hard water to hit PR surface. |

||

| − | |||

| − | PEii Technics O2: 30sec. May increase feature openings. |

||

| − | |||

| − | Metal Evaporation - EBeam#4 or EBeam#1 vertical/4-inch holder |

||

| − | |||

| − | Lift-off in NMP, facing down or vertical. |

||

Latest revision as of 16:32, 27 April 2022

Developed by Demis D. John, ~2017-2019

This process is intended for Deep-UV Exposure on the ASML DUV Stepper. PMGI is used as the underlayer, which is exposed at the same time as the imaging resist.

Adjust spin speed or switch to a different PMGI formulation to tailor the underlayer thickness to your desired metal thickness.

Tips

Please see our Bi-Layer Lift-Off Tutorial to understand the limitations and requirements for good lift-off.

- Remember that gaps in between adjacent metal traces can lift-off during the develop!

- Need underlayer thickness approx. 2x the desired metal thickness.

- The underlayer will develop laterally from both sides which can lift-off the imaging resist, so:

- Minimum gap between adjacent metals should then be: greater than 0.5 * underlayer thickness

- Want at least 30-50nm of underlayer width left to support the imaging resist, so the PR doesn't fall over/collapse.

- Make sure to use a vertical evaporation line-of-sight such as EBeam4 or EBeam1. EBeam3 is not vertical unless special care is taken.

Process Limits

This process is written with PMGI SF-5 @ 4krpm, which spins to about 130nm

- Maximum metal thickness = 130nm/2 ≈ 65nm (can possibly increase up to 130nm* 2/3 ≈ 85nm)

- Undercuts laterally about 130-140nm, so minimum gap between metals = (2 x 140nm) + ~30nm ≈ 350nm

Adjust the PMGI layer thickness to adjust these process limits.

PMGI could be spun thicker, or double-spun to get thicker underlayers (develop time & undercut will increase accordingly).

PMGI underlayer could be replaced with LOL1000/LOL2000, or another developable underlayer.

Suggested Process for Liftoff

| De-H2O Bake (eg. 220°C, 1m+)

- or - Technics O2 ash (300mT, 100W), 15sec |

Oxygen ash is faster and more effective |

| Spin PMGI SF-5 @ 4krpm (rcp 7) | |

| POLOS underside clean: 2000rpm, ACE/ISO/N2 | |

| PMGI-Bake: 220°C, 3min (BrewerSci lift-pin hotplate). | Can just place wafer directly onto hotplate surface.

Optionally can use lift-pins & Recipe "00 220deg, 3min Vac"; --> To prevent wafer sliding: Enable Vacuum with overhead valve, only for wafer landing and then turn off. |

| Spin UV-6-0.8 @ rcp 6 (3.5krpm) | |

| POLOS underside clean: 2000rpm, ACE/ISO/N2 | |

| Soft-Bake = 135°C, 1min (builtin hotplate) | |

| (check underside for particulates) | |

| ASML Exposure | |

| Default: Exp = 37.5mJ // foc = –0.10 | Try this exposure dose but might need to do a FocArray (smaller Image Distribution eg. 5x5) to find proper exposure. |

| PEB = 135°C, 1.5min (built-in hotplate) | |

| Dev (300MiF) = 50sec (CRITICAL time) | Use cassette & H2O rinse dish prepared

--> not stirring, instead very slow/gentle lift/drop at various angles or gentle swish just to mix developer slightly. |

| DI rinse | Very Gently! Dunk into prepared DI dish, and dump/fill gently 2x. Don’t allow direct hard water to hit PR surface. |

| PEii Technics O2: 30sec (100W/300mT) | May increase feature size openings by ~50nm. |

| Metal Evaporation

(insert steps) |

EBeam#4 or EBeam#1 with vertical/4-inch holders (not planetary) |

| Lift-off in NMP | Facing down or vertical.

Optional: going directly into continuous Ultrasonic can reduce residual particles. |

Data

• For PMGI Baked at 220°C for 3min, the PMGI dissolves in AZ 300MIF at a rate of approximately ~600nm/min.

Images / Examples