Difference between revisions of "Lift-Off with DUV Imaging + PMGI Underlayer"

Jump to navigation

Jump to search

(→Examples: insert SEM) |

(Minor updates to process) |

||

| Line 2: | Line 2: | ||

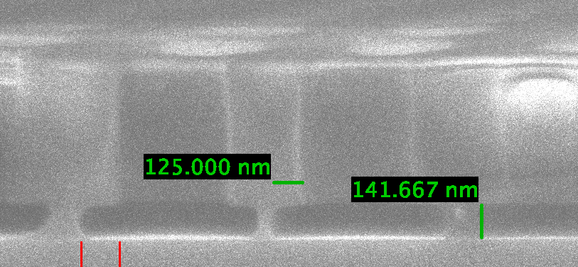

This process uses PMGI SF-5 @ 4krpm, which spins to about 130nm (maximum metal thickness = 130nm/3 ≈ 45nm) and undercuts laterally about 130-140nm (minimum gap between metals = (2 x 140nm) + 30nm ≈ 350nm). |

This process uses PMGI SF-5 @ 4krpm, which spins to about 130nm (maximum metal thickness = 130nm/3 ≈ 45nm) and undercuts laterally about 130-140nm (minimum gap between metals = (2 x 140nm) + 30nm ≈ 350nm). |

||

| + | |||

| + | Adjust spin speed or switch to a different PMGI formulation to tailor the underlayer thickness to your desired metal thickness. |

||

==Tips== |

==Tips== |

||

| Line 19: | Line 21: | ||

==Suggested Process for Liftoff== |

==Suggested Process for Liftoff== |

||

| − | *De-H2O Bake (eg. 220°C, 1m+). Optionally Oxygen ash instead. |

+ | *De-H2O Bake (eg. 220°C, 1m+). Optionally Oxygen ash instead (faster and more effective). |

| − | *HMDS soak 10s+ |

||

*Spin PMGI SF-5 @ 4krpm (rcp 7) |

*Spin PMGI SF-5 @ 4krpm (rcp 7) |

||

**--> POLOS underside clean: 2000rpm, ACE/ISO/N2 |

**--> POLOS underside clean: 2000rpm, ACE/ISO/N2 |

||

| − | *PMGI-Bake: 220°C, 3min (BrewerSci lift-pin hotplate). |

+ | *PMGI-Bake: 220°C, 3min (BrewerSci lift-pin hotplate). Can just place wafer directly onto hotplate surface. Optionally can use lift-pins & Recipe "'''''00 220deg, 3min Vac'''''"; Enable Vacuum with overhead valve, only for wafer landing and then turn off to prevent sliding. |

| − | **Recipe "'''''00 220deg, 3min Vac'''''". Enable Vacuum with overhead valve, only for wafer landing and then turn off. |

||

*Spin UV-6-0.8 @ rcp 6 (3.5krpm) |

*Spin UV-6-0.8 @ rcp 6 (3.5krpm) |

||

**--> POLOS underside clean: 2000rpm, ACE/ISO/N2 |

**--> POLOS underside clean: 2000rpm, ACE/ISO/N2 |

||

| Line 30: | Line 30: | ||

*(check underside for particulates) |

*(check underside for particulates) |

||

*ASML Exposure |

*ASML Exposure |

||

| − | ** |

+ | **Default: Exp = 37.5mJ // foc = –0.10 |

| − | * |

+ | **Try this exposure dose - might need to do a FocArray (smaller Image Distribution eg. 5x5) to find proper exposure. |

*PEB = 135°C, 1.5min (built-in hotplate) |

*PEB = 135°C, 1.5min (built-in hotplate) |

||

*Dev (300MiF) = 50sec (CRITICAL time) |

*Dev (300MiF) = 50sec (CRITICAL time) |

||

| − | **--> with cassette & H2O dish prepared |

+ | **--> with cassette & H2O rinse dish prepared |

| − | **--> not stirring, instead very slow/gentle lift/drop at various angles or gentle swish |

+ | **--> not stirring, instead very slow/gentle lift/drop at various angles or gentle swish just to mix developer slightly. |

*DI rinse : very Gently! Dunk into prepared DI dish, and dump/fill gently 2x. Don’t allow direct hard water to hit PR surface. |

*DI rinse : very Gently! Dunk into prepared DI dish, and dump/fill gently 2x. Don’t allow direct hard water to hit PR surface. |

||

| − | *PEii Technics O2: 30sec. May increase feature openings. |

+ | *PEii Technics O2: 30sec. May increase feature size openings. |

*Metal Evaporation - EBeam#4 or EBeam#1 vertical/4-inch holder |

*Metal Evaporation - EBeam#4 or EBeam#1 vertical/4-inch holder |

||

*Lift-off in NMP, facing down or vertical. |

*Lift-off in NMP, facing down or vertical. |

||

Revision as of 20:22, 7 September 2019

This process is intended for Deep-UV Exposure on the ASML DUV Stepper. PMGI is used as the underlayer, which is exposed at the same time as the imaging resist.

This process uses PMGI SF-5 @ 4krpm, which spins to about 130nm (maximum metal thickness = 130nm/3 ≈ 45nm) and undercuts laterally about 130-140nm (minimum gap between metals = (2 x 140nm) + 30nm ≈ 350nm).

Adjust spin speed or switch to a different PMGI formulation to tailor the underlayer thickness to your desired metal thickness.

Tips

Please see our [Bi-Layer Lift-Off Tutorial] to understand the limitations and requirements for good lift-off.

- Remember that gaps in between adjacent metal traces can lift-off during the develop!

- Need underlayer thickness 2x to 3x the desired metal thickness.

- The underlayer will develop laterally from both sides which can lift-off the imaging resist, so:

- Minimum gap between adjacent metals should then be: less than 0.5 * underlayer thickness

- Want at least 30-50nm of underlayer width left to support the imaging resist, so the PR doesn't fall over/collapse.

- Make sure to use a vertical evaporation - EBeam4 or EBeam1. EBeam3 is not vertical.

Suggested Process for Liftoff

- De-H2O Bake (eg. 220°C, 1m+). Optionally Oxygen ash instead (faster and more effective).

- Spin PMGI SF-5 @ 4krpm (rcp 7)

- --> POLOS underside clean: 2000rpm, ACE/ISO/N2

- PMGI-Bake: 220°C, 3min (BrewerSci lift-pin hotplate). Can just place wafer directly onto hotplate surface. Optionally can use lift-pins & Recipe "00 220deg, 3min Vac"; Enable Vacuum with overhead valve, only for wafer landing and then turn off to prevent sliding.

- Spin UV-6-0.8 @ rcp 6 (3.5krpm)

- --> POLOS underside clean: 2000rpm, ACE/ISO/N2

- Soft-Bake = 135°C, 1min (builtin hotplate)

- (check underside for particulates)

- ASML Exposure

- Default: Exp = 37.5mJ // foc = –0.10

- Try this exposure dose - might need to do a FocArray (smaller Image Distribution eg. 5x5) to find proper exposure.

- PEB = 135°C, 1.5min (built-in hotplate)

- Dev (300MiF) = 50sec (CRITICAL time)

- --> with cassette & H2O rinse dish prepared

- --> not stirring, instead very slow/gentle lift/drop at various angles or gentle swish just to mix developer slightly.

- DI rinse : very Gently! Dunk into prepared DI dish, and dump/fill gently 2x. Don’t allow direct hard water to hit PR surface.

- PEii Technics O2: 30sec. May increase feature size openings.

- Metal Evaporation - EBeam#4 or EBeam#1 vertical/4-inch holder

- Lift-off in NMP, facing down or vertical.

Examples