Difference between revisions of "Laser Scanning Confocal M-scope (Olympus LEXT)"

m (caption update) |

|||

| Line 16: | Line 16: | ||

=== Technique & Capabilities === |

=== Technique & Capabilities === |

||

[[File:Olypmus LEXT Example Profile Measurement.png|alt=Measurement of 5µm wide posts|thumb|205x205px|Example Height/Profile Measurement (click to enlarge)]] |

[[File:Olypmus LEXT Example Profile Measurement.png|alt=Measurement of 5µm wide posts|thumb|205x205px|Example Height/Profile Measurement (click to enlarge)]] |

||

| − | The LEXT allows you to take height measurements of features too small to reach with a physical Stylus needle, in a non-contact mode that is much faster than engaging an AFM tip. In addition, very large aspect-ratios can be measured - for example, 1mm depth x 50µm width. Confocal microscopy ensures that only surfaces that are in-focus will return a signal to the microscope detector. The LEXT sweeps the focus motor and captures a 2D scan of your sample at each focus step, taken with a blue laser ( |

+ | The LEXT allows you to take height measurements of features too small to reach with a physical Stylus needle, in a non-contact mode that is much faster than engaging an AFM tip. In addition, very large aspect-ratios can be measured - for example, 1mm depth x 50µm width. Confocal microscopy ensures that only surfaces that are in-focus will return a signal to the microscope detector. The LEXT sweeps the focus motor and captures a 2D scan of your sample at each focus step, taken with a blue laser (405 nm). After the scan, the height of each surface is calculated by the focus step which produced the highest laser intensity, and this is constructed into a 3D image by the OLS software. |

Because this is an optical method, films that are optically transparent to blue light and/or have transparent sloping sidewalls can produce non-physical measurements due to optical interference on the sample. In addition, features on the order of the laser wavelength can produce unreliable/non-physical data - for example, the data near (within ~500 nm) very steep slopes, or features ≤ 1.0 µm wide may not be reliable. |

Because this is an optical method, films that are optically transparent to blue light and/or have transparent sloping sidewalls can produce non-physical measurements due to optical interference on the sample. In addition, features on the order of the laser wavelength can produce unreliable/non-physical data - for example, the data near (within ~500 nm) very steep slopes, or features ≤ 1.0 µm wide may not be reliable. |

||

Revision as of 09:34, 20 April 2020

|

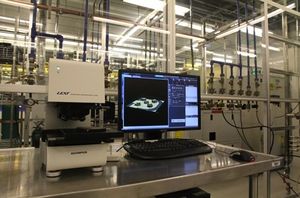

About

The LEXT OLS4000 3D Laser Measuring Microscope is designed for nanometer level imaging, 3D measurement and roughness measurement. Magnification ranges from 108x - 17,280x satisfy the needs of today's researchers. For a complete description of the tool and its capabilities, please see the above link to the manufacturer’s website.

Technique & Capabilities

The LEXT allows you to take height measurements of features too small to reach with a physical Stylus needle, in a non-contact mode that is much faster than engaging an AFM tip. In addition, very large aspect-ratios can be measured - for example, 1mm depth x 50µm width. Confocal microscopy ensures that only surfaces that are in-focus will return a signal to the microscope detector. The LEXT sweeps the focus motor and captures a 2D scan of your sample at each focus step, taken with a blue laser (405 nm). After the scan, the height of each surface is calculated by the focus step which produced the highest laser intensity, and this is constructed into a 3D image by the OLS software.

Because this is an optical method, films that are optically transparent to blue light and/or have transparent sloping sidewalls can produce non-physical measurements due to optical interference on the sample. In addition, features on the order of the laser wavelength can produce unreliable/non-physical data - for example, the data near (within ~500 nm) very steep slopes, or features ≤ 1.0 µm wide may not be reliable.

Surfaces that are opaque to the laser wavelength work best, although measurements on rectangular transparent edges do work relatively well. Edges of steps where light does not reflect in an ideal manner often produce non-physical features, typically manifesting as trenches/spikes right next to the sidewall.

Technically the height-resolution is specified as 10 nm (the height resolution of the focus motor), but in practice, noise and optical uncertainties worsen this spec.