Difference between revisions of "Deposition Data - temporary 2021-12-15"

(→Standard Cleaning Procedure (IBD): cleaning) |

|||

| (3 intermediate revisions by the same user not shown) | |||

| Line 10: | Line 10: | ||

==SiO<sub>2</sub> deposition (PECVD #1)== |

==SiO<sub>2</sub> deposition (PECVD #1)== |

||

| − | * SiO<sub>2</sub> [PECVD 1] Standard Recipe |

+ | *[https://docs.google.com/spreadsheets/d/1uqpg3sirsRbXdTFlxZ6_k3t0ovP0MtpFtICjpH0-prs/edit#gid= SiO<sub>2</sub><nowiki> [PECVD 1] Standard Recipe</nowiki>] |

| − | * |

+ | *[https://docs.google.com/spreadsheets/d/1fTDNXxpf4tgNYLIEs_jvehG1KvtXqqTRDBI7sHNAVvo/edit#gid=0 SiO<sub>2</sub><nowiki> [PECVD 1] Current Process Control Data</nowiki>] |

| − | * |

+ | *[https://docs.google.com/spreadsheets/d/1fTDNXxpf4tgNYLIEs_jvehG1KvtXqqTRDBI7sHNAVvo/edit#gid=1503619544 SiO<sub>2</sub><nowiki> [PECVD 1] Historical Data</nowiki>] - Oct. 2021 and earlier |

==SiN deposition (PECVD #1)== |

==SiN deposition (PECVD #1)== |

||

| − | * Si<sub>3</sub>N<sub>4</sub> [PECVD 1] Standard Recipe |

+ | *[https://docs.google.com/spreadsheets/d/1DGU745SeunYz4sLs1LpGKbtOYX-tQyBHEvVYcMxHRKE/edit#gid= Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 1] Standard Recipe</nowiki>] |

| − | * |

+ | *[https://docs.google.com/spreadsheets/d/1fTDNXxpf4tgNYLIEs_jvehG1KvtXqqTRDBI7sHNAVvo/edit#gid=98787450 Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 1] Current Process Control Data</nowiki>] |

| − | * |

+ | *[https://docs.google.com/spreadsheets/d/1fTDNXxpf4tgNYLIEs_jvehG1KvtXqqTRDBI7sHNAVvo/edit#gid=604790654 Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 1] Historical Data</nowiki>] - Oct. 2021 and earlier |

==Low Stress Si<sub>3</sub>N<sub>4</sub> (PECVD#1)== |

==Low Stress Si<sub>3</sub>N<sub>4</sub> (PECVD#1)== |

||

| − | * Low Stress Si<sub>3</sub>N<sub>4</sub> [PECVD 1] Standard Recipe |

+ | *[https://wiki.nanotech.ucsb.edu/wiki/images/4/4a/New_PECVD1-LS_SIN-Turner05recipe_2014_LS_SIN_recipe.pdf Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 1] Standard Recipe</nowiki>] |

| − | * |

+ | *[https://docs.google.com/spreadsheets/d/1fTDNXxpf4tgNYLIEs_jvehG1KvtXqqTRDBI7sHNAVvo/edit#gid=1515630363 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 1] Current Process Control Data</nowiki>] |

| − | * |

+ | *[https://docs.google.com/spreadsheets/d/1fTDNXxpf4tgNYLIEs_jvehG1KvtXqqTRDBI7sHNAVvo/edit#gid=934830479 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 1] Historical Data</nowiki>] - 2021-10 and earlier |

==SiO<sub>x</sub>N<sub>y</sub> deposition (PECVD #1)== |

==SiO<sub>x</sub>N<sub>y</sub> deposition (PECVD #1)== |

||

| Line 37: | Line 37: | ||

#Wet cleaning (start cleaning by using a cleanroom wipe sprayed with DI. Wipe chamber sidewalls with it. Finish cleaning by using the cleanroom wipe sprayed with IPA. ) |

#Wet cleaning (start cleaning by using a cleanroom wipe sprayed with DI. Wipe chamber sidewalls with it. Finish cleaning by using the cleanroom wipe sprayed with IPA. ) |

||

#Load the recipe for cleaning "CF4/O2 Clean" (edit the recipe and change ONLY time of cleaning). Follow instructions regarding a required time for cleaning. |

#Load the recipe for cleaning "CF4/O2 Clean" (edit the recipe and change ONLY time of cleaning). Follow instructions regarding a required time for cleaning. |

||

| + | # |

||

| + | |||

| + | {| class="wikitable" |

||

| + | |+Table of Cleaning Times |

||

| + | !Film Dep'd |

||

| + | !Cleaning Time |

||

| + | |- |

||

| + | |SiO<sub>2</sub> |

||

| + | |TBD |

||

| + | |- |

||

| + | |Si<sub>3</sub>N<sub>4</sub> |

||

| + | |TBD |

||

| + | |- |

||

| + | |SiOxNy |

||

| + | |Same as XYZ |

||

| + | |} |

||

| + | |||

| + | # |

||

===[https://wiki.nanotech.ucsb.edu/w/images/7/72/PECVD1-cleaning.png Standard Cleaning Recipe (PECVD#1): "CF4/O2 Clean"]=== |

===[https://wiki.nanotech.ucsb.edu/w/images/7/72/PECVD1-cleaning.png Standard Cleaning Recipe (PECVD#1): "CF4/O2 Clean"]=== |

||

| Line 46: | Line 64: | ||

==SiO<sub>2</sub> deposition (PECVD #2)== |

==SiO<sub>2</sub> deposition (PECVD #2)== |

||

| − | SiO<sub>2</sub> [PECVD 2] Standard Recipe |

||

| − | [https://docs.google.com/spreadsheets/d/ |

+ | *[https://docs.google.com/spreadsheets/d/1wCEcFj6ZMHR4QifngLXwz6dqbyf8hsVKu7bQbMS6EoA/edit#gid= SiO<sub>2</sub><nowiki> [PECVD 2] Standard Recipe</nowiki>] - "''STD SiO2''" |

| + | *[https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=1313651154 SiO<sub>2</sub><nowiki> [PECVD 2] Current Process Control Data</nowiki>] |

||

| + | *[https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=2024333220 SiO<sub>2</sub><nowiki> [PECVD 2] Historical Data</nowiki>] - Before Oct. 2021 |

||

| − | [https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=2024333220 SiO<sub>2</sub><nowiki> [PECVD 2] Historical Data</nowiki>] |

||

==SiN deposition (PECVD #2)== |

==SiN deposition (PECVD #2)== |

||

| + | *[https://docs.google.com/spreadsheets/d/1KS4HfhUJyYVep4H6CRAKpMRP5TA31F0qD-obQkKRnEI/edit#gid= Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Standard Recipe</nowiki>] - "''Nitride2''" |

||

| − | ===Standard Recipe=== |

||

| − | Si<sub>3</sub>N<sub>4</sub> [PECVD 2] |

+ | *[https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=773875841 Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Current Process Control Data</nowiki>] |

| + | *[https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=1153442266 Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Historical Data</nowiki>] - Before Oct. 2021 |

||

| − | |||

| − | ===Present Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=773875841 Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Present Data</nowiki>] |

||

| − | |||

| − | ===Historical Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=1153442266 Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Historical Data</nowiki>] |

||

==Low-Stress SiN deposition (PECVD #2)== |

==Low-Stress SiN deposition (PECVD #2)== |

||

''Low-Stress SilIcon Nitride, Si<sub>3</sub>N<sub>4</sub> (< 100 MPa)'' |

''Low-Stress SilIcon Nitride, Si<sub>3</sub>N<sub>4</sub> (< 100 MPa)'' |

||

| − | * Low Stress Si<sub>3</sub>N<sub>4</sub> [PECVD 2] Standard Recipe |

+ | *[https://docs.google.com/spreadsheets/d/1DzzI7aE61R7c6gyk6cGBdm9FtGrApiNJ4AL90ll2C8k/edit#gid= Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Standard Recipe</nowiki>] - "''LSNitride2''" |

| + | ***''Old Versions of the recipe:'' |

||

| − | * [https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=584923738 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Present Data</nowiki>] |

||

| + | ****[https://wiki.nanotech.ucsb.edu/wiki/images/a/a5/New_AdvPECVD-LS_Nitride2_300C_standard_recipe_LS_Nitride2_standard_recipe.pdf LS Nitride2 Standard Recipe 2014-5/9/2018] |

||

| − | * [https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=268003895 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Historical Data</nowiki>] |

||

| + | ****[https://wiki.nanotech.ucsb.edu/wiki/images/0/01/STD_LSNitride2_5-9-18.pdf STD LSNitride2 5/9/2018] |

||

| + | *[https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=584923738 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Current Process Control Data</nowiki>] |

||

| + | *[https://docs.google.com/spreadsheets/d/1iSW1eAAg824y9PYYLG9aiaw53PEJ-f9ofylpVlCDq9Y/edit#gid=268003895 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [PECVD 2] Historical Data - Before Oct. 2021</nowiki>] |

||

==Amorphous-Si deposition (PECVD #2)== |

==Amorphous-Si deposition (PECVD #2)== |

||

| Line 106: | Line 122: | ||

The system currently has Deuterated Silane (SiD<sub>4</sub>) installed - identical to the regular Silicon precursor SiH<sub>4</sub>, except that it significantly lowers optical absorption in the near-infrared due to shifted molecular vibrations/molecular weights. |

The system currently has Deuterated Silane (SiD<sub>4</sub>) installed - identical to the regular Silicon precursor SiH<sub>4</sub>, except that it significantly lowers optical absorption in the near-infrared due to shifted molecular vibrations/molecular weights. |

||

| − | ===[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=417334948https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=417334948 ICP-PECVD Plots]=== |

+ | ===[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=417334948https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=417334948 ICP-PECVD Plots] - TBD=== |

==Low Deposition Rate SiO<sub>2</sub> [ICP-PECVD]== |

==Low Deposition Rate SiO<sub>2</sub> [ICP-PECVD]== |

||

| + | *[https://docs.google.com/spreadsheets/d/1wocoCPOOEDQcZbXJJNaZs1sr9dXBZpn1wUyglL8IQrI/edit#gid=1199123007 Low Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] - Standard Recipe</nowiki>] - "''SiO2 LDR 250C''" |

||

| − | ===Standard Recipe=== |

||

| − | Low Deposition Rate SiO<sub>2</sub> [ICP-PECVD] |

+ | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=0 Low Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] - Current Process Control Data</nowiki>] |

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1916118198 Low Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] - Historical Data</nowiki>] - before Oct. 2021 |

||

| − | |||

| − | ===Present Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=0 Low Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] Present Data</nowiki>] |

||

| − | |||

| − | ===Historical Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1916118198 Low Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] Historical Data</nowiki>] |

||

==High Deposition Rate SiO<sub>2</sub> [ICP-PECVD]== |

==High Deposition Rate SiO<sub>2</sub> [ICP-PECVD]== |

||

| + | *[https://docs.google.com/spreadsheets/d/1OxHi5r9ifNvF8ODpIk6aoRevb4RdbbykwPVMm1g-yi4/edit#gid=1199123007 High Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] Standard Recipe</nowiki>] - "''SiO2 HDR 250C''" |

||

| − | ===Standard Recipe=== |

||

| − | High Deposition Rate SiO<sub>2</sub> [ICP-PECVD] |

+ | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1459210138 High Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] Present Data</nowiki>] |

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=939753086 High Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] Historical Data</nowiki>] |

||

| − | |||

| − | ===Present Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1459210138 High Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] Present Data</nowiki>] |

||

| − | ===Historical Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=939753086 High Deposition Rate SiO<sub>2</sub><nowiki> [ICP-PECVD] Historical Data</nowiki>] |

||

==Si<sub>3</sub>N<sub>4</sub> [ICP-PECVD]== |

==Si<sub>3</sub>N<sub>4</sub> [ICP-PECVD]== |

||

| + | *[https://docs.google.com/spreadsheets/d/1VrgS0cB2OcdZVTCnDAesgQCLRaAgEB_Iajc_OrhXOo0/edit#gid=1199123007 Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] Standard Recipe</nowiki>] - "''SiN 250C''" |

||

| − | ===Standard Recipe=== |

||

| − | Si<sub>3</sub>N<sub>4</sub> [ICP-PECVD] |

+ | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1459210138 Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] Current Process Control Data</nowiki>] |

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=782128304 Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] Historical Data</nowiki>] - before Oct. 2021 |

||

| − | |||

| − | ===Present Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1459210138 Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] Present Data</nowiki>] |

||

| − | |||

| − | ===Historical Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=782128304 Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] Historical Data</nowiki>] |

||

==Low Stress Si<sub>3</sub>N<sub>4</sub> [ICP-PECVD]== |

==Low Stress Si<sub>3</sub>N<sub>4</sub> [ICP-PECVD]== |

||

| + | *[https://docs.google.com/spreadsheets/d/1i2mE2K12EEulnCbO9KuU9PCcvHAmcGxTIXUF8x4IOWk/edit#gid=1199123007 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] Standard Recipe</nowiki>] - "''SiN Low Stress 250C''" |

||

| − | ===Standard Recipe=== |

||

| − | Low Stress Si<sub>3</sub>N<sub>4</sub> [ICP-PECVD] |

+ | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1459210138 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] Current Process Control Data</nowiki>] |

| + | *[https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1024532473 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] Historical Data</nowiki>] - before Oct. 2021 |

||

| − | |||

| − | ===Present Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1459210138 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] Present Data</nowiki>] |

||

| − | ===Historical Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/1CuDMKFTTzGLL6CP-FEI_9cOnUaIw-432ppDFssB59wY/edit#gid=1024532473 Low Stress Si<sub>3</sub>N<sub>4</sub><nowiki> [ICP-PECVD] Historical Data</nowiki>] |

||

==Standard Cleaning Procedure [ICP-PECVD]== |

==Standard Cleaning Procedure [ICP-PECVD]== |

||

You must edit the Post-Dep Clean recipe to correspond to your deposited thickness and material. See the [[ICP-PECVD (Unaxis VLR)#Documentation|Operating Procedure on the Unaxis Tool Page]] for details. |

You must edit the Post-Dep Clean recipe to correspond to your deposited thickness and material. See the [[ICP-PECVD (Unaxis VLR)#Documentation|Operating Procedure on the Unaxis Tool Page]] for details. |

||

| Line 157: | Line 155: | ||

===Standard Clean Recipe=== |

===Standard Clean Recipe=== |

||

| + | ''To Be Added'' |

||

| + | |||

=[[Ion Beam Deposition (Veeco NEXUS)]]= |

=[[Ion Beam Deposition (Veeco NEXUS)]]= |

||

| + | Ion-Beam Assisted Deposition - high density reactive sputtering, with angled/rotating fixtures. |

||

| − | + | [https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=2030038046 IBD Plots] - '''''To Be Added''''' |

|

| − | ==SiO<sub>2</sub> |

+ | ==SiO<sub>2</sub> deposition (IBD)== |

| + | *[https://wiki.nanotech.ucsb.edu/wiki/images/8/8d/New_IBD_SiO2_Standard_Recipe.pdf SiO<sub>2</sub><nowiki> [IBD] Standard Recipe</nowiki>] - "''1_SiO2_dep''" |

||

| − | ===Standard Recipe=== |

||

| + | *[https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=0 SiO<sub>2</sub><nowiki> [IBD] Current Process Control Data</nowiki>] |

||

| − | SiO<sub>2</sub> [IBD] Standard Recipe |

||

| + | *[https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=700537698 SiO<sub>2</sub><nowiki> [IBD] Historical Data</nowiki>] - Before Oct. 2021 |

||

| + | ====SiO<sub>2</sub> Thin-Film Properties (IBD)==== |

||

| − | ===Present Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=0 SiO<sub>2</sub><nowiki> [IBD] Present Data</nowiki>] |

||

| + | *Dep.rate: ≈ 5.2 nm/min (users must calibrate this prior to critical deps) |

||

| − | ===Historical Data=== |

||

| + | *HF Etch Rate ~350 nm/min |

||

| − | [https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=700537698 SiO<sub>2</sub><nowiki> [IBD] Historical Data</nowiki>] |

||

| + | *Stress ≈ -390MPa (compressive) |

||

| + | *Refractive Index: ≈ 1.494 |

||

| + | *[[wikipedia:Cauchy's_equation|Cauchy Parameters]] (350-2000nm): |

||

| + | **A = 1.480 |

||

| + | **B = 0.00498 |

||

| + | **C = -3.2606e-5 |

||

| − | ==Si<sub>3</sub>N<sub>4</sub> |

+ | ==Si<sub>3</sub>N<sub>4</sub> deposition (IBD)== |

| + | *[https://wiki.nanotech.ucsb.edu/wiki/images/d/d3/IBD_SiNdeposition.pdf Si<sub>3</sub>N<sub>4</sub><nowiki> [IBD] Standard Recipe</nowiki>] - "''1_Si3N4_Dep''" |

||

| − | ===Standard Recipe=== |

||

| + | *[https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=971672318 Si<sub>3</sub>N<sub>4</sub><nowiki> [IBD] Current Process Control Data</nowiki>] |

||

| − | Si<sub>3</sub>N<sub>4</sub> [IBD] Standard Recipe |

||

| + | *[https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=2093120876 Si<sub>3</sub>N<sub>4</sub><nowiki> [IBD] Historical Data</nowiki>] - before Oct. 2021 |

||

| + | ===Si<sub>3</sub>N<sub>4</sub> Thin-Film Properties (IBD)=== |

||

| − | ===Present Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=971672318 Si<sub>3</sub>N<sub>4</sub><nowiki> [IBD] Present Data</nowiki>] |

||

| + | *Deposition Rate: ≈ 4.10 nm/min (users must calibrate this prior to critical deps) |

||

| − | ===Historical Data=== |

||

| + | *HF Etch Rate: ~11nm/min |

||

| − | [https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=2093120876 Si<sub>3</sub>N<sub>4</sub><nowiki> [IBD] Historical Data</nowiki>] |

||

| + | *Stress ≈ -1590MPa (compressive) |

||

| − | ==Ta<sub>2</sub>O<sub>5</sub> [IBD]== |

||

| + | *Refractive Index: ≈ 1.969 |

||

| + | *[[wikipedia:Cauchy's_equation|Cauchy Parameters]] (350-2000nm): |

||

| + | **A = 2.000 |

||

| + | **B = 0.01974 |

||

| + | **C = 1.2478e-4 |

||

| + | ==Ta<sub>2</sub>O<sub>5</sub> deposition (IBD)== |

||

| − | ===Standard Recipe=== |

||

| − | Ta<sub>2</sub>O<sub>5</sub> [IBD] Standard Recipe |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/images/8/85/IBD_Ta2O5_deposition_details.pdf Ta<sub>2</sub>O<sub>5</sub><nowiki> [IBD] Standard Recipe</nowiki>] - "''1_Ta2O5_dep''" |

||

| − | ===Present Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=855566098 Ta<sub>2</sub>O<sub>5</sub><nowiki> [IBD] |

+ | *[https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=855566098 Ta<sub>2</sub>O<sub>5</sub><nowiki> [IBD] Current Process Control Data</nowiki>] |

| + | *[https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=1075234846 Ta<sub>2</sub>O<sub>5</sub><nowiki> [IBD] Historical Data</nowiki>] - before Oct. 2021 |

||

| + | ====Ta2O5 Thin-Film Properies (IBD)==== |

||

| − | ===Historical Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=1075234846 Ta<sub>2</sub>O<sub>5</sub><nowiki> [IBD] Historical Data</nowiki>] |

||

| − | ==Al<sub>2</sub>O<sub>3</sub> [IBD]== |

||

| + | *Ta2O5 1hr depositions: |

||

| − | ===Standard Recipe=== |

||

| + | *Deposition Rate: ≈ 7.8 nm/min (users must calibrate this prior to critical deps) |

||

| − | Al<sub>2</sub>O<sub>3</sub> [IBD] Standard Recipe |

||

| + | *HF Etch Rate ≈ 2 nm/min |

||

| + | *Stress ≈ -232MPa (compressive) |

||

| + | *Refractive Index: ≈ 2.172 |

||

| + | *[[wikipedia:Cauchy's_equation|Cauchy Parameters]] (350-2000nm): |

||

| + | **A = 2.1123 |

||

| + | **B = 0.018901 |

||

| + | **C = -0.016222 |

||

| + | ==Al<sub>2</sub>O<sub>3</sub> deposition (IBD)== |

||

| − | ===Present Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=713133870 Al<sub>2</sub>O<sub>3</sub><nowiki> [IBD] Present Data</nowiki>] |

||

| + | *Al<sub>2</sub>O<sub>3</sub> [IBD] Standard Recipe - "''1_Al2O3_dep''" |

||

| − | ===Historical Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid= |

+ | *[https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=713133870 Al<sub>2</sub>O<sub>3</sub><nowiki> [IBD] Present Data</nowiki>] |

| + | *[https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=1294329492 Al<sub>2</sub>O<sub>3</sub><nowiki> [IBD] Historical Data</nowiki>] |

||

| − | ==TiO<sub>2</sub> [IBD]== |

||

| + | ===Al2O3 Thin-Film Properties (IBD)=== |

||

| − | ===Standard Recipe=== |

||

| − | TiO<sub>2</sub> [IBD] Standard Recipe |

||

| + | **Deposition Rate ≈ 2.05nm/min (users must calibrate this prior to critical deps) |

||

| − | ===Present Data=== |

||

| + | **HF etch rate ≈ 167nm/min |

||

| − | [https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=834404663 TiO<sub>2</sub><nowiki> [IBD] Present Data</nowiki>] |

||

| + | **Stress ≈ -332MPa (compressive) |

||

| + | **Refractive Index: ≈ 1.656 |

||

| + | **[[wikipedia:Cauchy's_equation|Cauchy Parameters]] (350-2000nm): |

||

| + | ***A = ''To Be Added'' |

||

| + | ***B = |

||

| + | ***C = |

||

| + | **Absorbing < ~350nm |

||

| + | ==TiO<sub>2</sub> deposition (IBD)== |

||

| − | ===Historical Data=== |

||

| − | [https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=1327808550 TiO<sub>2</sub><nowiki> [IBD] Historical Data</nowiki>] |

||

| − | ==Standard Cleaning Procedure [ICP-PECVD]== |

||

| − | You must edit the Post-Dep Clean recipe to correspond to your deposited thickness and material. See the [[ICP-PECVD (Unaxis VLR)#Documentation|Operating Procedure on the Unaxis Tool Page]] for details. |

||

| + | *[https://wiki.nanotech.ucsb.edu/wiki/images/3/3b/New_IBD_TiO2_deposition.pdf TiO<sub>2</sub><nowiki> [IBD] Standard Recipe</nowiki>] - "''1_TiO2_dep''" |

||

| − | *SiNx etches at 20nm/min |

||

| + | *[https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=834404663 TiO<sub>2</sub><nowiki> [IBD] Current Process Control Data</nowiki>] |

||

| − | *SiO<sub>2</sub> etches at 40nm/min |

||

| + | *[https://docs.google.com/spreadsheets/d/11A0ac8NU51bmcQ_grQcq9wuPwWnfy1_9MNk2DEo5yyo/edit#gid=1327808550 TiO<sub>2</sub><nowiki> [IBD] Historical Data</nowiki>] |

||

| + | ===TiO<sub>2</sub> Thin-Film Properties (IBD)=== |

||

| − | ===Standard Clean Recipe=== |

||

| + | |||

| + | *Deposition Rate: ≈ 1.29 nm/min (users must calibrate this prior to critical deps) |

||

| + | *HF etch rate ~5.34nm/min |

||

| + | *Stress ≈ -445MPa (compressive) |

||

| + | *Refractive Index: ≈ 2.259 |

||

| + | *[[wikipedia:Cauchy's_equation|Cauchy Parameters]] (350-2000nm): |

||

| + | **A = 2.435 |

||

| + | **B = -4.9045e-4 |

||

| + | **C = 0.01309 |

||

| + | *Absorbing < ~350nm wavelength |

||

| + | |||

| + | ===SiO<sub>x</sub>N<sub>y</sub> deposition (IBD)=== |

||

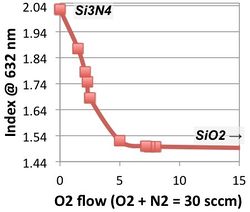

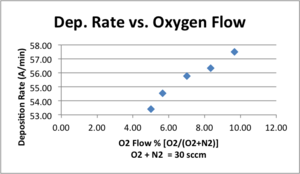

| + | These are some old (2010), initial characterizations only. A recipe improvement would be to increase the Assist O2+N2 = 60sccm total, increasing repeatability. Contact [[Demis D. John|Demis]] for more info. |

||

| + | {| |

||

| + | ![[File:IBD SiON Index @ 623nm vs. O2 Gas Flow - v3 - wiki.jpg|alt=plot showing varying refractive index between Si3N4 and SiO2|none|thumb|250x250px|IBD SiO<sub>x</sub>N<sub>y</sub>: Refractive Index vs. O2/N2 Flow.]] |

||

| + | ![[File:IBD SiON - Dep rate vs O2 flow - wiki.png|alt=Rate varies monotonically from 53-5 Å/min.|none|thumb|Dep. Rate of IBD SiO<sub>x</sub>N<sub>y</sub> vs. Assist O<sub>2</sub> flow.]] |

||

| + | |} |

||

| + | |||

| + | ==Standard Cleaning Procedure (IBD)== |

||

| + | You must edit the "''#_GridClean''"("#" is your group number) steps in your Process according to the following times: |

||

| + | |||

| + | *5min GridClean for 1hr or less deposition |

||

| + | *10min GridClean for up to 2hrs of dep. |

||

| + | *Do not deposit for longer than 2hrs - instead break up your Process into multiple 2-hr subroutines with cleans in between. See the recipe "''1_SiO2_Dep_Multi''" for an example. |

||

| + | ===Standard Grid-Clean Recipe=== |

||

| + | ''To Be Added'' |

||

Latest revision as of 00:07, 16 December 2021

NEW data templates - Demis 2021-12-15

Back to Vacuum Deposition Recipes

PECVD 1 (PlasmaTherm 790)

PECVD 1 Plots - SiO2, SiN and Particulate Count

SiO2 deposition (PECVD #1)

- SiO2 [PECVD 1] Standard Recipe

- SiO2 [PECVD 1] Current Process Control Data

- SiO2 [PECVD 1] Historical Data - Oct. 2021 and earlier

SiN deposition (PECVD #1)

- Si3N4 [PECVD 1] Standard Recipe

- Si3N4 [PECVD 1] Current Process Control Data

- Si3N4 [PECVD 1] Historical Data - Oct. 2021 and earlier

Low Stress Si3N4 (PECVD#1)

- Low Stress Si3N4 [PECVD 1] Standard Recipe

- Low Stress Si3N4 [PECVD 1] Current Process Control Data

- Low Stress Si3N4 [PECVD 1] Historical Data - 2021-10 and earlier

SiOxNy deposition (PECVD #1)

Standard Cleaning Procedure (PECVD #1)

The cleaning procedure is very important in order to have consistent result on this tool and also to keep particulate count low. After each deposition you should clean the tool following instructions carefully. The clean is done in two steps:

- Wet cleaning (start cleaning by using a cleanroom wipe sprayed with DI. Wipe chamber sidewalls with it. Finish cleaning by using the cleanroom wipe sprayed with IPA. )

- Load the recipe for cleaning "CF4/O2 Clean" (edit the recipe and change ONLY time of cleaning). Follow instructions regarding a required time for cleaning.

| Film Dep'd | Cleaning Time |

|---|---|

| SiO2 | TBD |

| Si3N4 | TBD |

| SiOxNy | Same as XYZ |

Standard Cleaning Recipe (PECVD#1): "CF4/O2 Clean"

Click the above link for a screenshot of the standard cleaning recipe, for which you will enter a custom time. The recipe is set up so that it will pop up a window for the cleaning time upon running the recipe - you do not need to edit the recipe before running it.

PECVD 2 (Advanced Vacuum)

PECVD 2 Plots

SiO2 deposition (PECVD #2)

- SiO2 [PECVD 2] Standard Recipe - "STD SiO2"

- SiO2 [PECVD 2] Current Process Control Data

- SiO2 [PECVD 2] Historical Data - Before Oct. 2021

SiN deposition (PECVD #2)

- Si3N4 [PECVD 2] Standard Recipe - "Nitride2"

- Si3N4 [PECVD 2] Current Process Control Data

- Si3N4 [PECVD 2] Historical Data - Before Oct. 2021

Low-Stress SiN deposition (PECVD #2)

Low-Stress SilIcon Nitride, Si3N4 (< 100 MPa)

- Low Stress Si3N4 [PECVD 2] Standard Recipe - "LSNitride2"

- Old Versions of the recipe:

- Low Stress Si3N4 [PECVD 2] Current Process Control Data

- Low Stress Si3N4 [PECVD 2] Historical Data - Before Oct. 2021

Amorphous-Si deposition (PECVD #2)

Standard Cleaning Procedure (PECVD #2)

The cleaning procedure is very important in order to have consistent result on this tool and also to keep particulate count low. After each deposition you should clean the tool following instructions carefully. The clean is done in two steps:

- (If >29min dep time) Wet cleaning: Start cleaning by using a cleanroom wipe sprayed with DI. Wipe upper chamber sidewalls with it. Finish cleaning by using the cleanroom wipe sprayed with IPA & wiping again.

- Load the recipe for cleaning "STD CF4/O2 Clean" (edit the recipe and change ONLY time of cleaning). Follow instructions regarding required time for cleaning.

Standard Clean Recipe (PECVD#2): "STD CF4/O2 Clean"

Click the above link for a screenshot of the standard cleaning recipe, for which you will enter a custom time. The recipe is set up so that it will pop up a window for the cleaning time upon running the recipe - you do not need to edit the recipe before running it.

Clean Times (PECVD#2)

| Film Deposited | Cleaning Time (Dry) |

|---|---|

| SiO2 | 1 min. clean for every 1 min. deposition |

| Si3N4 | 1 min. clean for every 7 min of deposition |

| If > 29min total dep time

(Season + Dep) |

Wet Clean the Upper Lid/Chamber

DI water then Isopropyl Alcohol on chamber wall & portholes |

ICP-PECVD (Unaxis VLR)

2020-02: New recipes have been characterized for low particulate count and repeatability. Only staff-supplied recipes are allowed in the tool. Please follow the new procedures to ensure low particle counts in the chamber.

The system currently has Deuterated Silane (SiD4) installed - identical to the regular Silicon precursor SiH4, except that it significantly lowers optical absorption in the near-infrared due to shifted molecular vibrations/molecular weights.

ICP-PECVD Plots - TBD

Low Deposition Rate SiO2 [ICP-PECVD]

- Low Deposition Rate SiO2 [ICP-PECVD] - Standard Recipe - "SiO2 LDR 250C"

- Low Deposition Rate SiO2 [ICP-PECVD] - Current Process Control Data

- Low Deposition Rate SiO2 [ICP-PECVD] - Historical Data - before Oct. 2021

High Deposition Rate SiO2 [ICP-PECVD]

- High Deposition Rate SiO2 [ICP-PECVD] Standard Recipe - "SiO2 HDR 250C"

- High Deposition Rate SiO2 [ICP-PECVD] Present Data

- High Deposition Rate SiO2 [ICP-PECVD] Historical Data

Si3N4 [ICP-PECVD]

- Si3N4 [ICP-PECVD] Standard Recipe - "SiN 250C"

- Si3N4 [ICP-PECVD] Current Process Control Data

- Si3N4 [ICP-PECVD] Historical Data - before Oct. 2021

Low Stress Si3N4 [ICP-PECVD]

- Low Stress Si3N4 [ICP-PECVD] Standard Recipe - "SiN Low Stress 250C"

- Low Stress Si3N4 [ICP-PECVD] Current Process Control Data

- Low Stress Si3N4 [ICP-PECVD] Historical Data - before Oct. 2021

Standard Cleaning Procedure [ICP-PECVD]

You must edit the Post-Dep Clean recipe to correspond to your deposited thickness and material. See the Operating Procedure on the Unaxis Tool Page for details.

- SiNx etches at 20nm/min

- SiO2 etches at 40nm/min

Standard Clean Recipe

To Be Added

Ion Beam Deposition (Veeco NEXUS)

Ion-Beam Assisted Deposition - high density reactive sputtering, with angled/rotating fixtures.

IBD Plots - To Be Added

SiO2 deposition (IBD)

- SiO2 [IBD] Standard Recipe - "1_SiO2_dep"

- SiO2 [IBD] Current Process Control Data

- SiO2 [IBD] Historical Data - Before Oct. 2021

SiO2 Thin-Film Properties (IBD)

- Dep.rate: ≈ 5.2 nm/min (users must calibrate this prior to critical deps)

- HF Etch Rate ~350 nm/min

- Stress ≈ -390MPa (compressive)

- Refractive Index: ≈ 1.494

- Cauchy Parameters (350-2000nm):

- A = 1.480

- B = 0.00498

- C = -3.2606e-5

Si3N4 deposition (IBD)

- Si3N4 [IBD] Standard Recipe - "1_Si3N4_Dep"

- Si3N4 [IBD] Current Process Control Data

- Si3N4 [IBD] Historical Data - before Oct. 2021

Si3N4 Thin-Film Properties (IBD)

- Deposition Rate: ≈ 4.10 nm/min (users must calibrate this prior to critical deps)

- HF Etch Rate: ~11nm/min

- Stress ≈ -1590MPa (compressive)

- Refractive Index: ≈ 1.969

- Cauchy Parameters (350-2000nm):

- A = 2.000

- B = 0.01974

- C = 1.2478e-4

Ta2O5 deposition (IBD)

- Ta2O5 [IBD] Standard Recipe - "1_Ta2O5_dep"

- Ta2O5 [IBD] Current Process Control Data

- Ta2O5 [IBD] Historical Data - before Oct. 2021

Ta2O5 Thin-Film Properies (IBD)

- Ta2O5 1hr depositions:

- Deposition Rate: ≈ 7.8 nm/min (users must calibrate this prior to critical deps)

- HF Etch Rate ≈ 2 nm/min

- Stress ≈ -232MPa (compressive)

- Refractive Index: ≈ 2.172

- Cauchy Parameters (350-2000nm):

- A = 2.1123

- B = 0.018901

- C = -0.016222

Al2O3 deposition (IBD)

- Al2O3 [IBD] Standard Recipe - "1_Al2O3_dep"

- Al2O3 [IBD] Present Data

- Al2O3 [IBD] Historical Data

Al2O3 Thin-Film Properties (IBD)

- Deposition Rate ≈ 2.05nm/min (users must calibrate this prior to critical deps)

- HF etch rate ≈ 167nm/min

- Stress ≈ -332MPa (compressive)

- Refractive Index: ≈ 1.656

- Cauchy Parameters (350-2000nm):

- A = To Be Added

- B =

- C =

- Absorbing < ~350nm

TiO2 deposition (IBD)

- TiO2 [IBD] Standard Recipe - "1_TiO2_dep"

- TiO2 [IBD] Current Process Control Data

- TiO2 [IBD] Historical Data

TiO2 Thin-Film Properties (IBD)

- Deposition Rate: ≈ 1.29 nm/min (users must calibrate this prior to critical deps)

- HF etch rate ~5.34nm/min

- Stress ≈ -445MPa (compressive)

- Refractive Index: ≈ 2.259

- Cauchy Parameters (350-2000nm):

- A = 2.435

- B = -4.9045e-4

- C = 0.01309

- Absorbing < ~350nm wavelength

SiOxNy deposition (IBD)

These are some old (2010), initial characterizations only. A recipe improvement would be to increase the Assist O2+N2 = 60sccm total, increasing repeatability. Contact Demis for more info.

Standard Cleaning Procedure (IBD)

You must edit the "#_GridClean"("#" is your group number) steps in your Process according to the following times:

- 5min GridClean for 1hr or less deposition

- 10min GridClean for up to 2hrs of dep.

- Do not deposit for longer than 2hrs - instead break up your Process into multiple 2-hr subroutines with cleans in between. See the recipe "1_SiO2_Dep_Multi" for an example.

Standard Grid-Clean Recipe

To Be Added