Difference between revisions of "Contact Aligner (SUSS MA-6)"

(→Detailed Specifications: updated system specs) |

(Updated SOP with BSA steps, removed old BSA steps) |

||

| (4 intermediate revisions by 2 users not shown) | |||

| Line 12: | Line 12: | ||

}} |

}} |

||

==About== |

==About== |

||

| − | This system is a dual-use mask aligner and wafer-bond aligner. Mask alignment is used for contact and proximity exposure processes. Exposures can be performed with gaps programmable from 10 um to 300 um in 1 um increments. Automatic wedge error compensation (WEC) is used to ensure that the mask and wafer are parallel. Lithography can be performed on wafers from 2” to 6” in diameter. Piece parts are better handled on the MJB-3 aligners. An automated image capture system is used for alignment at 5x, 10x, or 20x magnification. The system is fitted with visible, bottom-side optics for back-side alignment capability. The lamp is a 350 W Hg-Arc lamp, providing significant power in the g-h-and i-line regime. Integrated light level sensing ensures proper exposure doses as the lamp degrades. Bond alignment can be performed on 3” to 6” wafers. The bond alignment is performed with special fixturing to allow aligned samples to be transferred to the Karl-Suss SB6 system. |

+ | This system is a dual-use mask aligner and wafer-bond aligner. Mask alignment is used for contact and proximity exposure processes. Exposures can be performed with gaps programmable from 10 um to 300 um in 1 um increments. Automatic wedge error compensation (WEC) is used to ensure that the mask and wafer are parallel. Lithography can be performed on wafers from 2” to 6” in diameter. Piece parts are better handled on the MJB-3 aligners. An automated image capture system is used for back side alignment at 5x, 10x, or 20x magnification. The system is fitted with visible, bottom-side optics for back-side alignment capability. The lamp is a 350 W Hg-Arc lamp, providing significant power in the g-h-and i-line regime. Integrated light level sensing ensures proper exposure doses as the lamp degrades. Bond alignment can be performed on 3” to 6” wafers. The bond alignment is performed with special fixturing to allow aligned samples to be transferred to the Karl-Suss SB6 system. |

==Detailed Specifications== |

==Detailed Specifications== |

||

| Line 21: | Line 21: | ||

**Hard Contact: <1.5 µm |

**Hard Contact: <1.5 µm |

||

**Soft Contact: <2.5 µm |

**Soft Contact: <2.5 µm |

||

| − | **Proximity (@ 20 µm): <3.0µm |

+ | **Proximity (@ 20 µm): <3.0µm |

<nowiki>*</nowiki> Resolution achieved on 150 mm Si-wafer with 1.2 µm thick AZ 4110 |

<nowiki>*</nowiki> Resolution achieved on 150 mm Si-wafer with 1.2 µm thick AZ 4110 |

||

| − | * |

+ | *Topside alignment accuracy: down to 0.5 µm |

| − | * |

+ | *Backside alignment accuracy: down to 1 µm |

*Automatic Light Intensity Drift Compensation: |

*Automatic Light Intensity Drift Compensation: |

||

| Line 34: | Line 34: | ||

*Stored video imaging for precise, repeatable alignment |

*Stored video imaging for precise, repeatable alignment |

||

*Visible Back-Side Alignment System |

*Visible Back-Side Alignment System |

||

| − | *Lithography for 2” to 6” diameter wafers |

+ | *Lithography for 2” to 6” diameter wafers - 6 mm maximum thickness |

*Pieces down to 5 x 5 mm - Please be aware of the stage movement range: X ± 10mm, Y ± 5 mm |

*Pieces down to 5 x 5 mm - Please be aware of the stage movement range: X ± 10mm, Y ± 5 mm |

||

*Bond alignment for 3” to 6” wafers, integrates with SB6 bond |

*Bond alignment for 3” to 6” wafers, integrates with SB6 bond |

||

| Line 41: | Line 41: | ||

==Documentation== |

==Documentation== |

||

| − | *[https:// |

+ | *[https://wiki.nanotech.ucsb.edu/w/images/4/41/MA-6_SOP_Rev_D.pdf MA-6 Standard Operating Procedure, includes BSA] |

| − | *[[Suss MA-6 Backside Alignment QuickStart]] |

||

*[https://signupmonkey.ece.ucsb.edu/wiki/images/7/75/MA-6_Exp_Mode_Visual_Aid.pdf MA-6 Exposure Mode Information] |

*[https://signupmonkey.ece.ucsb.edu/wiki/images/7/75/MA-6_Exp_Mode_Visual_Aid.pdf MA-6 Exposure Mode Information] |

||

Revision as of 10:24, 13 July 2021

|

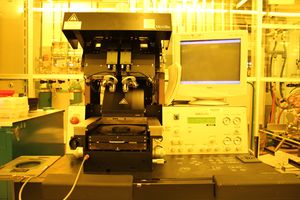

About

This system is a dual-use mask aligner and wafer-bond aligner. Mask alignment is used for contact and proximity exposure processes. Exposures can be performed with gaps programmable from 10 um to 300 um in 1 um increments. Automatic wedge error compensation (WEC) is used to ensure that the mask and wafer are parallel. Lithography can be performed on wafers from 2” to 6” in diameter. Piece parts are better handled on the MJB-3 aligners. An automated image capture system is used for back side alignment at 5x, 10x, or 20x magnification. The system is fitted with visible, bottom-side optics for back-side alignment capability. The lamp is a 350 W Hg-Arc lamp, providing significant power in the g-h-and i-line regime. Integrated light level sensing ensures proper exposure doses as the lamp degrades. Bond alignment can be performed on 3” to 6” wafers. The bond alignment is performed with special fixturing to allow aligned samples to be transferred to the Karl-Suss SB6 system.

Detailed Specifications

- 350 W Hg arc lamp, broadband exposure with Suss UV400 Optics (350 - 450 nm)

- Resolution (per Manufacturer*):

- Vacuum Contact: <0.8 µm

- Hard Contact: <1.5 µm

- Soft Contact: <2.5 µm

- Proximity (@ 20 µm): <3.0µm

* Resolution achieved on 150 mm Si-wafer with 1.2 µm thick AZ 4110

- Topside alignment accuracy: down to 0.5 µm

- Backside alignment accuracy: down to 1 µm

- Automatic Light Intensity Drift Compensation:

- Channel 1 is calibrated to 9 mW/cm² at 365 nm

- Channel 2 is calibrated to 15 mW/cm² at 405 nm

- Programmable exposure gaps of 10-300 um in 1 um steps

- Stored video imaging for precise, repeatable alignment

- Visible Back-Side Alignment System

- Lithography for 2” to 6” diameter wafers - 6 mm maximum thickness

- Pieces down to 5 x 5 mm - Please be aware of the stage movement range: X ± 10mm, Y ± 5 mm

- Bond alignment for 3” to 6” wafers, integrates with SB6 bond

- Other wafer sizes can be discussed with staff