Difference between revisions of "Automated Coat/Develop System (S-Cubed Flexi)"

Jump to navigation

Jump to search

(indicated which PR's/chems are availabelf for general use) |

|||

| Line 12: | Line 12: | ||

|toolid=67 |

|toolid=67 |

||

}} |

}} |

||

| + | ''This Tool is now available for training - please contact the supervisor. 2022-11-01'' |

||

| ⚫ | |||

=About= |

=About= |

||

| Line 27: | Line 27: | ||

**< 100 particles on 100mm wafer |

**< 100 particles on 100mm wafer |

||

*Photoresists/Underlayers Available: |

*Photoresists/Underlayers Available: |

||

| − | **UV6-0.8 |

+ | **UV6-0.8 |

**DS-K101-304 |

**DS-K101-304 |

||

| ⚫ | |||

| − | **PMMA |

||

| + | **PMGI SF11 - '''<u>NOT FOR GENERAL USE AT THIS TIME</u>''' |

||

| − | **PMGI SF11 |

||

| + | **PMGI SF5 - '''<u>NOT FOR GENERAL USE AT THIS TIME</u>''' |

||

| − | **PMGI SF5 |

||

*Solvents Available: |

*Solvents Available: |

||

| − | **EBR100 |

+ | **EBR100 (wafer backside cleaning) |

| − | *Developers Available: |

+ | *Developers Available: |

| + | **AZ 300 MiF - '''<u>NOT FOR GENERAL USE AT THIS TIME</u>''' |

||

| − | **AZ 300 MiF |

||

=Process Information= |

=Process Information= |

||

| Line 44: | Line 44: | ||

=Operating Procedures= |

=Operating Procedures= |

||

| − | *[[S-Cubed Flexi - Operating Procedure|Standard Operating Procedure]] - For running pre-written recipes only. |

+ | **[[S-Cubed Flexi - Operating Procedure|Standard Operating Procedure]] - For running pre-written recipes only. |

Revision as of 14:19, 8 November 2022

| ||||||||||||||||||||||||||||||||

This Tool is now available for training - please contact the supervisor. 2022-11-01

About

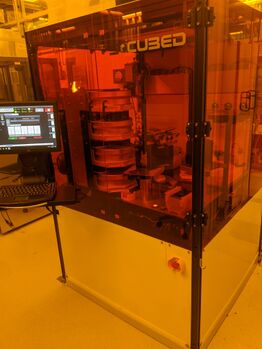

The S3-Coater is a Coater/Developer system that has one photoresist spinner, one developer spinner and 4 hotplates each with independent temperature control and a chill plate. A central robot picks your wafer/s from one of 2 cassettes, processes them and returns them to the cassette. The system is recipe driven with a high degree of process control and minimal backside contamination, and coats photoresists with low particle counts/streaks and high uniformity.

At this time only full size substrates are allowed on this system. The S3 Coater is still in process development and not open for general use.

Detailed Specifications

- Wafer Size: 100mm (150mm possible but not set up)

- PR Coating Properties:

- Uniformity < 1.0%

- < 100 particles on 100mm wafer

- Photoresists/Underlayers Available:

- UV6-0.8

- DS-K101-304

- PMMA - NOT FOR PUBLIC USE AT THIS TIME

- PMGI SF11 - NOT FOR GENERAL USE AT THIS TIME

- PMGI SF5 - NOT FOR GENERAL USE AT THIS TIME

- Solvents Available:

- EBR100 (wafer backside cleaning)

- Developers Available:

- AZ 300 MiF - NOT FOR GENERAL USE AT THIS TIME

Process Information

- Recipe Page for S-Cubed Coater: Lithography Recipes > Automated Coat/Develop System Recipes (S-Cubed Flexi)

- See the Photolith. Chemicals page for info on the installed resists.

Operating Procedures

- Standard Operating Procedure - For running pre-written recipes only.