Difference between revisions of "ASML Stepper 3 Standard Operating Procedure"

(→Running a focus and/or exposure matrix: discussion of "process window" and "tolerance") |

|||

| Line 1: | Line 1: | ||

'''Regular Procedures for ASML Deep-UV Stepper #3''' |

'''Regular Procedures for ASML Deep-UV Stepper #3''' |

||

| − | == |

+ | ==Normal User Procedures== |

| − | === |

+ | ===Cleaning the back-sides of wafers === |

Very important! '''It is crucial that particles do not get tracked into the system's exposure chuck'''. Sub-micron features will have resolution issues if a particle alters the local wafer focus, affecting everyone's processes. |

Very important! '''It is crucial that particles do not get tracked into the system's exposure chuck'''. Sub-micron features will have resolution issues if a particle alters the local wafer focus, affecting everyone's processes. |

||

| − | # Make sure all work surfaces/spin chucks/hot plates are cleaned! Don’t use wipes, instead place baked wafers directly on cleaned steel surfaces. |

||

| − | # Cleaning residue of AR2 or DSK101: This technique is much better than trying to wipe. Use clean gloves and hold the wafer edges with your hands. |

||

| − | ## After spin coating, place wafer upside down in POLOS spinner using non-contact chuck. |

||

| − | ## Set spin speed to 2000rpm. |

||

| − | ## Spin wafer, wait until at top speed. |

||

| − | ## Squirt Acetone on sample back for 3 seconds. Followed by ISO for 3 sec. |

||

| − | ## Spin Dry while blowing with N2. |

||

| − | ## Remove wafer and do bake as normal |

||

| − | # Cleaning residues of UV210, UV6, UNV2300, or PEK-162C1 |

||

| − | ## After baking and cooling, place wafer upside down in POLOS spinner using non-contact chuck. |

||

| − | ## Set spin speed to 2000rpm. |

||

| − | ## Spin wafer, wait until at top speed. |

||

| − | ## Squirt Acetone on sample back for 3 seconds. Followed by ISO for 3 sec. |

||

| − | ## Spin Dry while blowing with N2. |

||

| − | # Check back-side of wafer thoroughly for particulates before loading into system! If you see particulates, try to blow then off with high N2 flow first, you may need to get physical with a razor blade to remove stubborn particles. |

||

| + | #Make sure all work surfaces/spin chucks/hot plates are cleaned! Don’t use wipes, instead place baked wafers directly on cleaned steel surfaces. |

||

| − | === Reticle Unloading and Loading === |

||

| + | #Cleaning residue of AR2 or DSK101: This technique is much better than trying to wipe. Use clean gloves and hold the wafer edges with your hands. |

||

| − | # Material Handler '''(Mat Hdl)''' button near top right of main software window |

||

| + | ##After spin coating, place wafer upside down in POLOS spinner using non-contact chuck. |

||

| − | ## Remove reticles from machine |

||

| + | ##Set spin speed to 2000rpm. |

||

| − | ## Exchange reticle box |

||

| + | ##Spin wafer, wait until at top speed. |

||

| − | ## Unlock Box #3 |

||

| + | ##Squirt Acetone on sample back for 3 seconds. Followed by ISO for 3 sec. |

||

| − | ### Only box 3 is for general use. |

||

| + | ##Spin Dry while blowing with N2. |

||

| − | # Physically Remove desired reticle pod(s), green indicator at box should be lit and all reticles should be up inside box, not down into machine. |

||

| + | ##Remove wafer and do bake as normal |

||

| − | # Use manual box opener to open reticle box. Move arm slowly. |

||

| + | #Cleaning residues of UV210, UV6, UNV2300, or PEK-162C1 |

||

| − | # Remove Pod Lid |

||

| + | ##After baking and cooling, place wafer upside down in POLOS spinner using non-contact chuck. |

||

| − | # Remove (or add) reticle to pod. Two stars ('''*''') on reticle should be in front. |

||

| + | ##Set spin speed to 2000rpm. |

||

| − | # Place Pod lid back on |

||

| + | ##Spin wafer, wait until at top speed. |

||

| − | # Close Pod using arm, move arm slowly |

||

| + | ##Squirt Acetone on sample back for 3 seconds. Followed by ISO for 3 sec. |

||

| − | # Place Pod back in stepper |

||

| + | ##Spin Dry while blowing with N2. |

||

| − | # '''(Read)''' Box #3 - takes a few minutes |

||

| + | #Check back-side of wafer thoroughly for particulates before loading into system! If you see particulates, try to blow then off with high N2 flow first, you may need to get physical with a razor blade to remove stubborn particles. |

||

| − | # Exit the Material Handler. The Material Handler can be run in parallel with other operations. |

||

| − | === |

+ | ===Reticle Unloading and Loading=== |

| − | *# Open lid, Remove cassette |

||

| − | *# Clean underside of wafers thoroughly, looking very carefully for particles. |

||

| − | *## '''Make sure backs of wafers are extremely clean!''' No Particles! No residues! Be extra careful and attentive to this detail! See Brian Thibeault for instructions. |

||

| − | *# Place wafers in slots |

||

| − | *# Place cassette back. Make sure cassette is pulled ''back &'' snugly in place |

||

| − | *# Close Lid. |

||

| + | #Material Handler '''(Mat Hdl)''' button near top right of main software window |

||

| − | === Running a Job – Normal operation === |

||

| + | ##Remove reticles from machine |

||

| − | *# Batch Control |

||

| + | ##Exchange reticle box |

||

| − | *## Task Streaming |

||

| + | ##Unlock Box #3 |

||

| − | *### Wait until wafers are read by machine |

||

| + | ###Only box 3 is for general use. |

||

| − | *### Ensure all other job's status is "Completed" or "Aborted". |

||

| + | #Physically Remove desired reticle pod(s), green indicator at box should be lit and all reticles should be up inside box, not down into machine. |

||

| − | *### Task: '''Append Batch''' (or select a previous batch and copy) |

||

| + | #Use manual box opener to open reticle box. Move arm slowly. |

||

| − | *### Enter Batch ID first, Hit Return to apply change |

||

| + | #Remove Pod Lid |

||

| − | *### Press '''Select''' Button under Job Name and navigate to your job |

||

| + | #Remove (or add) reticle to pod. Two stars ('''*''') on reticle should be in front. |

||

| − | *### Click on '''Layer ID''' to get a list of layers you can expose: Select layer you want to shoot. |

||

| + | #Place Pod lid back on |

||

| − | *### Enter number of wafers in '''Batch Size''' |

||

| + | #Close Pod using arm, move arm slowly |

||

| − | *### Batch Type is P for production run (see below for doing a FEM) |

||

| + | #Place Pod back in stepper |

||

| − | *### Verify ''Energy'', ''Focus Offset'', ''Ilumination Mode'', ''NA'', ''Sigma'' and change as desired |

||

| + | #'''(Read)''' Box #3 - takes a few minutes |

||

| − | *#### Click through the Images to be shot by this Layer and verify for each Image. |

||

| + | #Exit the Material Handler. The Material Handler can be run in parallel with other operations. |

||

| − | *#### Click through the Images to be shot by this Layer, and make sure all the "Reticle ID" shown are loaded into the Reticle system. (Toggle the "View" button on the System View to see loaded Reticle ID's.) |

||

| − | *### Hit Action: '''Apply''' button to register all changes |

||

| − | *### Press '''Accept''' Button at Top |

||

| − | *### Press '''Continue''' Button to execute batch. (May be a short delay before this becomes active.) |

||

| − | *### If batch has general failure: |

||

| − | *### On the “Abort Batch” error window: click (HELP) button to see the cause of error - photograph this screen. Then Choose the ('''clear litho cluster''') option |

||

| − | *### unload your Reticle when done, follow procedure above. |

||

| + | ===Wafer Load=== |

||

| − | === Running a focus and/or exposure matrix === |

||

| + | |||

| − | ''Focus/Exposure Arrays are used to determine the proper exposure dose & focus offset for your lithography. Especially important for high-resolution layers. Make sure your entire litho process remains constant (spins, bakes, develop times etc.) between the FEA and your real sample lithos.'' |

||

| + | *#Open lid, Remove cassette |

||

| − | # ''Optional'': Copy you job to a new job file with the layers/images you want to shoot, but which does not fill the entire wafer to the edges - it instead has only a ~6x6-cm wide array of die (set in the '''''Wafer Layout > Image Distribution''''' section of your program). This ensures that our SEMs can view the full array (The extreme edges of a 4-inch wafer are not possible to image on our SEMs due to motor limits) and simplifies calculations while inspecting the exposed wafer. |

||

| + | *#Clean underside of wafers thoroughly, looking very carefully for particles. |

||

| − | # Follow "''Running a Job''" procedure above, until Step 7 |

||

| + | *##'''Make sure backs of wafers are extremely clean!''' No Particles! No residues! Be extra careful and attentive to this detail! See Brian Thibeault for instructions. |

||

| − | # Under '''Batch Type''': |

||

| + | *#Place wafers in slots |

||

| − | ## Choose '''E''' for exposure snake (with flat down, first exposure lower left increments to the right, snakes in serpentine manner around entire wafer). Enter starting exposure in mJ (bottom-left die) and incremental exposure in mJ (increments up). |

||

| + | *#Place cassette back. Make sure cassette is pulled ''back &'' snugly in place |

||

| − | ## Choose '''F''' for focus snake (with flat down, first exposure lower left increments to the right, snakes around entire array). Enter starting focus offset (bottom-left die) and incremental focus for the snake (increments up). |

||

| + | *#Close Lid. |

||

| − | ## Choose '''M''' for Focus-Exposure-Matrix (FEM). Center cell 0,0 is the nominal Exposure Energy and Focus value you enter. The array is incremented up and down from the nominal value. By default, exposure Energy varies by columns, Focus by Rows. See schematic below. |

||

| + | |||

| − | # Verify non-varied parameters as well as Ilumination Mode, NA, Sigma and change as desired. |

||

| + | ===Running a Job – Normal operation=== |

||

| − | # Hit '''Action: (Apply)''' button to register all changes |

||

| + | |||

| − | # Press '''Accept''' Button at Top |

||

| + | *#Batch Control |

||

| − | # Press '''Continue''' Button to execute batch. |

||

| + | *##Task Streaming |

||

| − | # When the batch is complete, select the batch in the Task ist, and click '''Batch:''' '''(Report)'''. The '''"Test Exposure Data"''' section of the report shows the exposure params for each die location. This is very useful during your inspection, and it is recommended that you bring a photograph or copy of this exposure matrix table with you when inspecting on the microscope/SEM. |

||

| + | *###Wait until wafers are read by machine |

||

| + | *###Ensure all other job's status is "Completed" or "Aborted". |

||

| + | *###Task: '''Append Batch''' (or select a previous batch and copy) |

||

| + | *###Enter Batch ID first, Hit Return to apply change |

||

| + | *###Press '''Select''' Button under Job Name and navigate to your job |

||

| + | *###Click on '''Layer ID''' to get a list of layers you can expose: Select layer you want to shoot. |

||

| + | *###Enter number of wafers in '''Batch Size''' |

||

| + | *###Batch Type is P for production run (see below for doing a FEM) |

||

| + | *###Verify ''Energy'', ''Focus Offset'', ''Ilumination Mode'', ''NA'', ''Sigma'' and change as desired |

||

| + | *####Click through the Images to be shot by this Layer and verify for each Image. |

||

| + | *####Click through the Images to be shot by this Layer, and make sure all the "Reticle ID" shown are loaded into the Reticle system. (Toggle the "View" button on the System View to see loaded Reticle ID's.) |

||

| + | *###Hit Action: '''Apply''' button to register all changes |

||

| + | *###Press '''Accept''' Button at Top |

||

| + | *###Press '''Continue''' Button to execute batch. (May be a short delay before this becomes active.) |

||

| + | *###If batch has general failure: |

||

| + | *###On the “Abort Batch” error window: click (HELP) button to see the cause of error - photograph this screen. Then Choose the ('''clear litho cluster''') option |

||

| + | *###unload your Reticle when done, follow procedure above. |

||

| + | |||

| + | ===Running a focus and/or exposure matrix=== |

||

| + | ''Focus-Exposure Matrix/Arrays (FEM or FEA) are used to determine the proper exposure dose & focus offset for your lithography. Especially important for high-resolution layers. Make sure your entire litho process remains constant (spins, bakes, develop times etc.) between the FEA and your real sample lithos.'' |

||

| + | |||

| + | #''Optional'': Copy you job to a new job file with the layers/images you want to shoot, but which does not fill the entire wafer to the edges - it instead has only a ~6x6-cm wide array of die (set in the '''''Wafer Layout > Image Distribution''''' section of your program). This ensures that our SEMs can view the full array (The extreme edges of a 4-inch wafer are not possible to image on our SEMs due to motor limits) and simplifies calculations while inspecting the exposed wafer. |

||

| + | #Follow "''Running a Job''" procedure above, until Step 7 |

||

| + | #Under '''Batch Type''': |

||

| + | ##Choose '''E''' for exposure snake (with flat down, first exposure lower left increments to the right, snakes in serpentine manner around entire wafer). Enter starting exposure in mJ (bottom-left die) and incremental exposure in mJ (increments up). |

||

| + | ##Choose '''F''' for focus snake (with flat down, first exposure lower left increments to the right, snakes around entire array). Enter starting focus offset (bottom-left die) and incremental focus for the snake (increments up). |

||

| + | ##Choose '''M''' for Focus-Exposure-Matrix (FEM). Center cell 0,0 is the nominal Exposure Energy and Focus value you enter. The array is incremented up and down from the nominal value. By default, exposure Energy varies by columns, Focus by Rows. See schematic below. |

||

| + | #Verify non-varied parameters as well as Ilumination Mode, NA, Sigma and change as desired. |

||

| + | #Hit '''Action: (Apply)''' button to register all changes |

||

| + | ##Check ALL the Images in the job! Use the '''(Preset)''' button to apply to all Images in the job. |

||

| + | #Press '''Accept''' Button at Top |

||

| + | #Press '''Continue''' Button to execute batch. |

||

| + | #When the batch is complete, select the batch in the Task ist, and click '''Batch:''' '''(Report)'''. The '''"Test Exposure Data"''' section of the report shows the exposure params for each die location. This is very useful during your inspection, and it is recommended that you bring a photograph or copy of this exposure matrix table with you when inspecting on the microscope/SEM. |

||

| + | |||

| + | ==== Tips for FEM analysis ==== |

||

| + | You need to find the '''center of the ''Viable Process Window''''' - meaning you need to see the BAD dose (too high + too low) and BAD focus (too high + too low) then choose a Dose+Focus in the ''middle'' of this range. This allows your process to work even if the focus or some other process varies. |

||

| + | |||

| + | You'll need to decide what "good enough" looks like on your feature inspection - this is your process '''''tolerance'''''. For example instead of looking for "''the feature that is exactly 300nm wide''", you may want to look for Dose/Focus where "''the feature is between 250-350nm, or 300nm±50nm''". |

||

| + | |||

| + | A '''common mistake is to look for "''the best die''"''' - but this one good die could be (and often is) at the edge of the working process window, so a small focus variation (wafer thickness or lab temperature) will put your process outside the process window - you'll have chosen a very tight process that easily goes out of spec with random fluctuation in the process. |

||

{| |

{| |

||

![[File:Stepper 3 - FEM Energy Meander Schematic.png|alt=Stepper 3 - FEM Energy Meander Schematic|none|thumb|335x335px|Ordering of Energy/Focus for "Meander" mode.]] |

![[File:Stepper 3 - FEM Energy Meander Schematic.png|alt=Stepper 3 - FEM Energy Meander Schematic|none|thumb|335x335px|Ordering of Energy/Focus for "Meander" mode.]] |

||

Revision as of 12:23, 11 November 2021

Regular Procedures for ASML Deep-UV Stepper #3

Normal User Procedures

Cleaning the back-sides of wafers

Very important! It is crucial that particles do not get tracked into the system's exposure chuck. Sub-micron features will have resolution issues if a particle alters the local wafer focus, affecting everyone's processes.

- Make sure all work surfaces/spin chucks/hot plates are cleaned! Don’t use wipes, instead place baked wafers directly on cleaned steel surfaces.

- Cleaning residue of AR2 or DSK101: This technique is much better than trying to wipe. Use clean gloves and hold the wafer edges with your hands.

- After spin coating, place wafer upside down in POLOS spinner using non-contact chuck.

- Set spin speed to 2000rpm.

- Spin wafer, wait until at top speed.

- Squirt Acetone on sample back for 3 seconds. Followed by ISO for 3 sec.

- Spin Dry while blowing with N2.

- Remove wafer and do bake as normal

- Cleaning residues of UV210, UV6, UNV2300, or PEK-162C1

- After baking and cooling, place wafer upside down in POLOS spinner using non-contact chuck.

- Set spin speed to 2000rpm.

- Spin wafer, wait until at top speed.

- Squirt Acetone on sample back for 3 seconds. Followed by ISO for 3 sec.

- Spin Dry while blowing with N2.

- Check back-side of wafer thoroughly for particulates before loading into system! If you see particulates, try to blow then off with high N2 flow first, you may need to get physical with a razor blade to remove stubborn particles.

Reticle Unloading and Loading

- Material Handler (Mat Hdl) button near top right of main software window

- Remove reticles from machine

- Exchange reticle box

- Unlock Box #3

- Only box 3 is for general use.

- Physically Remove desired reticle pod(s), green indicator at box should be lit and all reticles should be up inside box, not down into machine.

- Use manual box opener to open reticle box. Move arm slowly.

- Remove Pod Lid

- Remove (or add) reticle to pod. Two stars (*) on reticle should be in front.

- Place Pod lid back on

- Close Pod using arm, move arm slowly

- Place Pod back in stepper

- (Read) Box #3 - takes a few minutes

- Exit the Material Handler. The Material Handler can be run in parallel with other operations.

Wafer Load

- Open lid, Remove cassette

- Clean underside of wafers thoroughly, looking very carefully for particles.

- Make sure backs of wafers are extremely clean! No Particles! No residues! Be extra careful and attentive to this detail! See Brian Thibeault for instructions.

- Place wafers in slots

- Place cassette back. Make sure cassette is pulled back & snugly in place

- Close Lid.

Running a Job – Normal operation

- Batch Control

- Task Streaming

- Wait until wafers are read by machine

- Ensure all other job's status is "Completed" or "Aborted".

- Task: Append Batch (or select a previous batch and copy)

- Enter Batch ID first, Hit Return to apply change

- Press Select Button under Job Name and navigate to your job

- Click on Layer ID to get a list of layers you can expose: Select layer you want to shoot.

- Enter number of wafers in Batch Size

- Batch Type is P for production run (see below for doing a FEM)

- Verify Energy, Focus Offset, Ilumination Mode, NA, Sigma and change as desired

- Click through the Images to be shot by this Layer and verify for each Image.

- Click through the Images to be shot by this Layer, and make sure all the "Reticle ID" shown are loaded into the Reticle system. (Toggle the "View" button on the System View to see loaded Reticle ID's.)

- Hit Action: Apply button to register all changes

- Press Accept Button at Top

- Press Continue Button to execute batch. (May be a short delay before this becomes active.)

- If batch has general failure:

- On the “Abort Batch” error window: click (HELP) button to see the cause of error - photograph this screen. Then Choose the (clear litho cluster) option

- unload your Reticle when done, follow procedure above.

- Task Streaming

- Batch Control

Running a focus and/or exposure matrix

Focus-Exposure Matrix/Arrays (FEM or FEA) are used to determine the proper exposure dose & focus offset for your lithography. Especially important for high-resolution layers. Make sure your entire litho process remains constant (spins, bakes, develop times etc.) between the FEA and your real sample lithos.

- Optional: Copy you job to a new job file with the layers/images you want to shoot, but which does not fill the entire wafer to the edges - it instead has only a ~6x6-cm wide array of die (set in the Wafer Layout > Image Distribution section of your program). This ensures that our SEMs can view the full array (The extreme edges of a 4-inch wafer are not possible to image on our SEMs due to motor limits) and simplifies calculations while inspecting the exposed wafer.

- Follow "Running a Job" procedure above, until Step 7

- Under Batch Type:

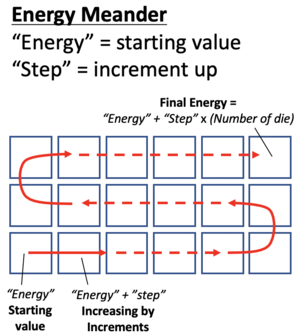

- Choose E for exposure snake (with flat down, first exposure lower left increments to the right, snakes in serpentine manner around entire wafer). Enter starting exposure in mJ (bottom-left die) and incremental exposure in mJ (increments up).

- Choose F for focus snake (with flat down, first exposure lower left increments to the right, snakes around entire array). Enter starting focus offset (bottom-left die) and incremental focus for the snake (increments up).

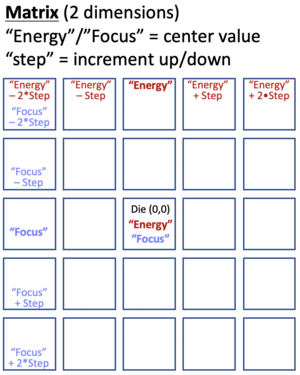

- Choose M for Focus-Exposure-Matrix (FEM). Center cell 0,0 is the nominal Exposure Energy and Focus value you enter. The array is incremented up and down from the nominal value. By default, exposure Energy varies by columns, Focus by Rows. See schematic below.

- Verify non-varied parameters as well as Ilumination Mode, NA, Sigma and change as desired.

- Hit Action: (Apply) button to register all changes

- Check ALL the Images in the job! Use the (Preset) button to apply to all Images in the job.

- Press Accept Button at Top

- Press Continue Button to execute batch.

- When the batch is complete, select the batch in the Task ist, and click Batch: (Report). The "Test Exposure Data" section of the report shows the exposure params for each die location. This is very useful during your inspection, and it is recommended that you bring a photograph or copy of this exposure matrix table with you when inspecting on the microscope/SEM.

Tips for FEM analysis

You need to find the center of the Viable Process Window - meaning you need to see the BAD dose (too high + too low) and BAD focus (too high + too low) then choose a Dose+Focus in the middle of this range. This allows your process to work even if the focus or some other process varies.

You'll need to decide what "good enough" looks like on your feature inspection - this is your process tolerance. For example instead of looking for "the feature that is exactly 300nm wide", you may want to look for Dose/Focus where "the feature is between 250-350nm, or 300nm±50nm".

A common mistake is to look for "the best die" - but this one good die could be (and often is) at the edge of the working process window, so a small focus variation (wafer thickness or lab temperature) will put your process outside the process window - you'll have chosen a very tight process that easily goes out of spec with random fluctuation in the process.