Difference between revisions of "ASML Stepper 3 Dicing Guide Programming"

Jump to navigation

Jump to search

(initial page, included screenshot and basic programming) |

(Update: state doesn’t work and workaround.) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

<blockquote>''How to program the ASML DUV Stepper #3 to place dicing guides in between die.''</blockquote> |

<blockquote>''How to program the ASML DUV Stepper #3 to place dicing guides in between die.''</blockquote> |

||

| + | UPDATE: doesn’t work: Ning tried this and found these patterns were too difficult to see on the disconfirm saw. Demis: new method, use ASML’s Alignment Mark distribution function to use SPM-X/Y marks as dicing guides. Carefully not to distribute too many - there is a software limit on number of exposures per Image. |

||

| − | * Determine a lithography step in the fabrication process during which the addition of dicing guides (crosses) |

+ | * Determine a lithography step in the fabrication process during which the addition of dicing guides (crosses) would be acceptable and visible during dicing. There are both positive and negative versions of the Cross pattern. |

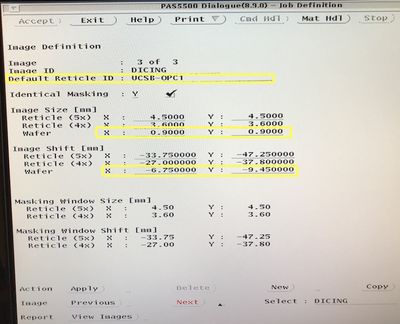

* When programming the job, add an new Image in <code>Wafer Layout > Image Definition</code> for the DicingGuides image, as so: |

* When programming the job, add an new Image in <code>Wafer Layout > Image Definition</code> for the DicingGuides image, as so: |

||

** Reticle ID: "'''UCSB-OPC1'''" (hyphenated) |

** Reticle ID: "'''UCSB-OPC1'''" (hyphenated) |

||

| + | ** For <u>Positive PR image</u>: |

||

| ⚫ | |||

| − | ** Image |

+ | *** Image Size (Wafer): X = 0.90000; Y = 0.90000 mm |

| ⚫ | |||

| − | ** [[File:UCSB Dicing Guides - IMG 1199 annotated.jpg|alt=ASML Programming: Image Definition Screen|none|thumb|400x400px|ASML Programming |

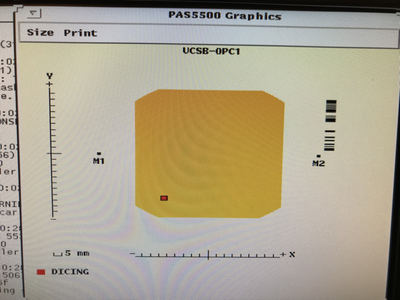

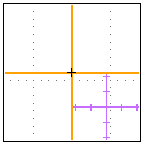

+ | *** [[File:UCSB Dicing Guides - IMG 1199 annotated.jpg|alt=ASML Programming: Image Definition Screen|none|thumb|400x400px|ASML Programming (Positive PR) Image Definition Screen]][[File:UCSB Dicing Guides - Image Location on Reticle - 800px.png|alt=Image Definition: Resulting location on Reticle screenshot|none|thumb|400x400px|Image Definition (Positive PR): Location on Reticle]][[File:GlobalMulti POS - Screen Shot 2018-07-23 at 11.17.23 AM.png|alt=Positive PR Alignment Mark schematic|none|thumb|Positive PR Alignment Mark. Will center the large Cross.]] |

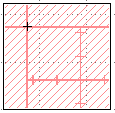

| + | **For <u>Negative PR Image</u>: |

||

| + | *** Image Size (wafer scale): X = 0.710000 ; Y = 0.710000 mm |

||

| + | *** Image Shift (wafer scale): X = 6.750000 ; Y = -9.450000 mm[[File:GlobalMulti NEG - Screen Shot 2018-07-23 at 11.22.19 AM.png|alt=Negative PR pattern schematic|none|thumb|Negative PR pattern]] |

||

| + | *** ''More info on either pattern can be [[ASML Stepper 3 - UCSB Test Reticles|found here]].'' |

||

* Under <code>Wafer Layout > Image Distribution</code>, add an <code>'''Image-to-Cell Shift'''</code> of '''half the die X/Y size''', and <code>Apply</code> to all die, to place the marks at the corner of every die. |

* Under <code>Wafer Layout > Image Distribution</code>, add an <code>'''Image-to-Cell Shift'''</code> of '''half the die X/Y size''', and <code>Apply</code> to all die, to place the marks at the corner of every die. |

||

| − | ** The software will only let you place the die at the upper-right (''+X,+Y'') corner. To include the lower-left corners, you will need to make sure you enabled the <code>Wafer Layout > Cell Structure > Die Definition > # of Dies & Minimum per Cell</code> options |

+ | ** The software will only let you place the die at the upper-right (''+X,+Y'') corner. To include the lower-left corners, you will need to make sure you enabled the <code>Wafer Layout > Cell Structure > Die Definition > # of Dies & Minimum per Cell</code> options too shoot partial die at the wafer edges. |

** Make sure they don't expose over any of your other alignment marks! |

** Make sure they don't expose over any of your other alignment marks! |

||

Latest revision as of 11:07, 30 January 2021

How to program the ASML DUV Stepper #3 to place dicing guides in between die.

UPDATE: doesn’t work: Ning tried this and found these patterns were too difficult to see on the disconfirm saw. Demis: new method, use ASML’s Alignment Mark distribution function to use SPM-X/Y marks as dicing guides. Carefully not to distribute too many - there is a software limit on number of exposures per Image.

- Determine a lithography step in the fabrication process during which the addition of dicing guides (crosses) would be acceptable and visible during dicing. There are both positive and negative versions of the Cross pattern.

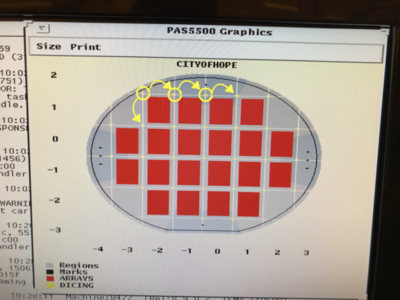

- When programming the job, add an new Image in

Wafer Layout > Image Definitionfor the DicingGuides image, as so:- Reticle ID: "UCSB-OPC1" (hyphenated)

- For Positive PR image:

- Image Size (Wafer): X = 0.90000; Y = 0.90000 mm

- Image Shift (Wafer): X = -6.750000; Y= -9.450000 mm

- For Negative PR Image:

- Image Size (wafer scale): X = 0.710000 ; Y = 0.710000 mm

- Image Shift (wafer scale): X = 6.750000 ; Y = -9.450000 mm

- More info on either pattern can be found here.

- Under

Wafer Layout > Image Distribution, add anImage-to-Cell Shiftof half the die X/Y size, andApplyto all die, to place the marks at the corner of every die.- The software will only let you place the die at the upper-right (+X,+Y) corner. To include the lower-left corners, you will need to make sure you enabled the

Wafer Layout > Cell Structure > Die Definition > # of Dies & Minimum per Celloptions too shoot partial die at the wafer edges. - Make sure they don't expose over any of your other alignment marks!

- The software will only let you place the die at the upper-right (+X,+Y) corner. To include the lower-left corners, you will need to make sure you enabled the